Processes of Complete Network Server Rack Tray Brackets OEM Service:

Our comprehensive production process for the Network Server Rack Tray Bracket is designed to ensure precision, quality, and complete customization. From detailed planning based on your drawings to meticulous after-sales support, every step is managed with care. Contact us to learn more about our step-by-step process and request your quote.

Develop a Production Solution Based on the Drawings:

Starting with your technical drawings, our engineering team crafts a detailed production plan tailored to your specifications. We analyze every design element, material requirement, and performance parameter to formulate a roadmap that ensures optimal manufacturability and quality. This plan outlines each production phase, including key milestones and quality checkpoints, ensuring that the final product not only meets but exceeds your expectations. By collaborating closely with you, we ensure that all technical nuances are addressed and that the plan is fully aligned with your project goals. Ready to see your design come to life? Contact us today for a consultation and quote.

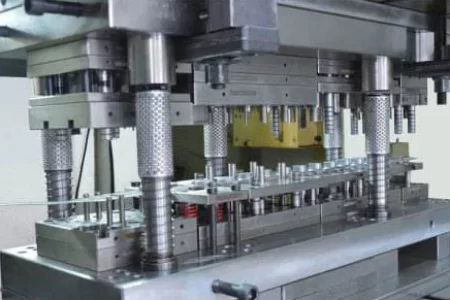

Mold Making:

Our mold-making process begins once the production plan is finalized. Skilled technicians utilize advanced CAD software and precision machining techniques to create molds that accurately reflect your design requirements. The molds are fabricated from high-quality materials and undergo rigorous testing to ensure they produce consistent, reliable components. This stage is critical for ensuring that every bracket fits perfectly and performs as intended. By investing in precision and quality at this stage, we set the foundation for a product that meets the highest standards. Interested in learning more about our mold-making process? Reach out today!

Sample Trial Production and Adjustment:

After mold creation, we move to the sample trial production phase. Initial samples are produced and then thoroughly inspected to verify that all design specifications are met. Our quality control team conducts tests to identify any potential adjustments needed in material properties or processing techniques. Feedback from this phase is crucial, and we promptly make refinements to optimize performance and durability. Once the samples meet our stringent standards, production settings are finalized for full-scale manufacturing. This process ensures that every bracket produced is of exceptional quality. Contact us now to discuss how our sample trial process can benefit your project.

Quality Control Plan Formulation:

Quality is integrated into our production from the start. Following sample approval, our dedicated quality control team formulates a comprehensive quality control plan. This plan includes detailed inspection protocols for every stage of production, from raw material verification to final assembly testing. Real-time monitoring systems and periodic audits ensure that every component adheres to our high standards. By embedding quality checks at each production step, we minimize defects and guarantee consistent performance. Our commitment to excellence means that you can trust our brackets to deliver reliability and durability. For more details on our quality control process, get in touch today.

Production Scheduling:

Efficient production scheduling is key to our operational success. After finalizing the production plan and quality protocols, our project managers create a detailed schedule that aligns manufacturing phases with delivery timelines. This schedule incorporates advanced planning tools to synchronize material procurement, machine allocation, and workforce shifts. Built-in buffers ensure flexibility for quality checks and adjustments, maintaining smooth workflow and timely delivery. Our systematic scheduling allows us to handle both small custom orders and large-scale projects with equal precision. Interested in our production timelines? Contact us for more information and a personalized quote.

Raw Material Procurement:

Our procurement team sources only premium-grade raw materials that meet the exacting standards required for Network Server Rack Tray Brackets. We partner with reliable suppliers and conduct rigorous quality tests on every batch to ensure material consistency and performance. By maintaining strong supplier relationships and leveraging bulk purchasing advantages, we secure competitive pricing and timely delivery. This careful selection process is the cornerstone of our high-quality production, ensuring that each bracket performs reliably under demanding conditions. For more details about our raw material sourcing practices, reach out to our team today.

Laser Cutting:

The cutting process employs advanced machinery to precisely cut raw materials into the exact dimensions specified in your design. Computer-controlled tools ensure accuracy and minimal waste, setting the stage for flawless component fabrication. Our skilled operators oversee the process, verifying that each cut meets strict tolerance requirements. This attention to detail is critical for ensuring that subsequent manufacturing steps align perfectly. By using state-of-the-art cutting techniques, we maintain the high precision required for durable and reliable tray brackets. Contact us to learn more about our cutting process and how it enhances product quality.

Bending:

Following the cutting phase, the bending process shapes the metal into the required forms. Our advanced bending equipment, combined with skilled technicians, ensures that every bend adheres to precise angle and curvature specifications. This step is essential for forming the structural integrity of the bracket. Automated controls and regular quality checks guarantee consistency and repeatability in every batch. The result is a product that not only meets your design requirements but also performs reliably in demanding server environments. For additional information on our bending process, please contact our sales team.

Stamping:

The stamping phase involves using precision presses to form detailed features and contours into the metal components. Our computer-controlled stamping process ensures high repeatability and accuracy, producing intricate designs that enhance both function and aesthetics. Every stamp is monitored for quality, and adjustments are made immediately to ensure conformity to design tolerances. This process is integral to creating the fine details that distinguish a high-quality tray bracket from the rest. To learn more about our stamping capabilities, feel free to contact us and discuss your project requirements.

Welding:

In the welding stage, individual components are seamlessly joined to form a cohesive tray bracket assembly. Utilizing a blend of automated and manual welding techniques, our process ensures strong, durable bonds that meet stringent performance standards. Each weld is inspected for consistency, strength, and precision, ensuring that the final assembly can withstand operational stresses. Our welding process is designed to maintain both the functional and aesthetic integrity of the bracket. If you'd like to explore our welding methods further, contact our expert team for a detailed discussion.

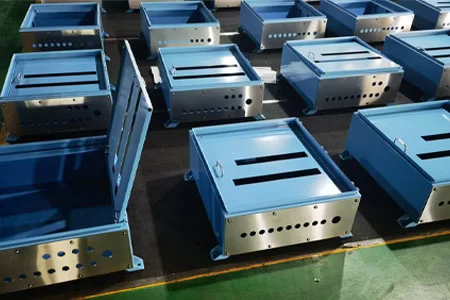

Surface Treatment:

Surface treatment enhances the durability and corrosion resistance of our Network Server Rack Tray Brackets. Using environmentally friendly coatings and advanced finishing techniques, each component receives a uniform, robust finish that withstands harsh environments. This stage is critical in not only elevating the product's visual appeal but also extending its operational life. Rigorous quality inspections ensure that every treated surface meets our high standards. Discover how our surface treatment process can add value to your project by reaching out for more details today.

Assembly:

During the assembly phase, all components are meticulously brought together to form the final Network Server Rack Tray Bracket. Our assembly lines blend automated precision with skilled manual craftsmanship, ensuring every connection is secure and properly aligned. Detailed checklists and quality inspections are employed at each step, guaranteeing that the finished product meets all design specifications and quality benchmarks. The result is a bracket that is both robust and aesthetically refined, ready to support your network infrastructure. For more insights into our assembly process, please contact us and request further information.

Packaging & Delivery:

Once assembled, each Network Server Rack Tray Bracket is carefully packaged to ensure safe transit and optimal protection. Our packaging process employs custom-designed materials that secure the product against damage during shipping and storage. Every package is clearly labeled with product specifications and handling instructions, ensuring a seamless logistics experience. This final stage is executed with the same precision and care as every other phase, guaranteeing that your order arrives in pristine condition. Contact us today to learn more about our packaging standards and how we safeguard your investment.

After-sales Service:

Our commitment to you extends beyond production. With our dedicated after-sales service, we offer ongoing support for return, replenishment, and exchange. Our knowledgeable service team is always ready to assist, ensuring that your product performs optimally. Whether you need installation guidance or post-sale support, we are just a call or message away. Experience a partnership that truly cares about your success—contact us for more details on our comprehensive after-sales service.