HULK Metal is one of the well-known sheet metal spinning factories in China, and has passed ISO 9001 certification. Since 2000, we have been committed to integrating a more complete supply chain to provide more thoughtful services to global customers. As

HULK Metal Provide Better Sheet Metal Spinning Parts OEM Service.

Sheet Metal Spinning Factory In China

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

HULK Metal's sheet metal spinning factory has passed ISO 9001 certification, with more than a dozen advanced spinning machines, 5 laser cutting machines, and a variety of welding machines, and can accept orders for a variety of complex processes. The quality control center has advanced instruments to complete the inspection of sheet metal spinning parts with higher precision. Choosing a suitable factory can save you a lot of time, energy and money. We have integrated a complete supply chain in China and can provide a full range of services such as raw material procurement, production, quality inspection, packaging, and transportation. Quality assurance service is also one of the services we provide. It is both our confidence in our products and the greatest guarantee for you.

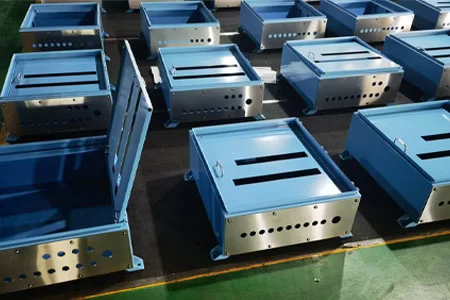

Sheet Metal Spinning Factory Show

Here are photos and introduction of our factory during mold making, cutting, production, and quality inspection. You can contact us at any time to visit the factory and place your order with us after understanding our production capacity.

-

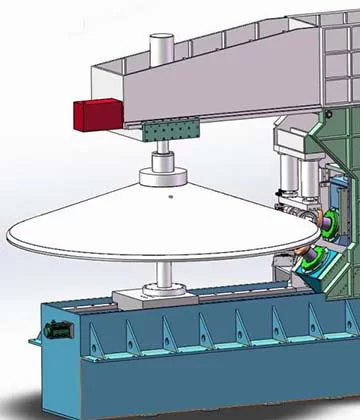

01Design Molds & Programming

The technicians will design the mold drawing according to the drawing and design the program used by the CNC spinning machine according to the drawing parameters, so that the production can be completed more efficiently.

-

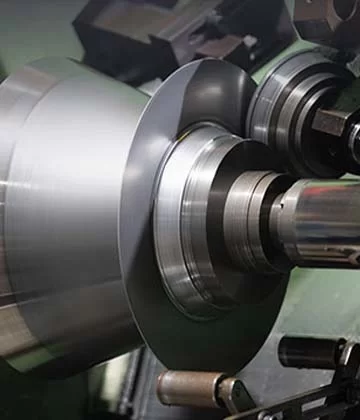

02Spinning

This is when we produce metal spun parts.

-

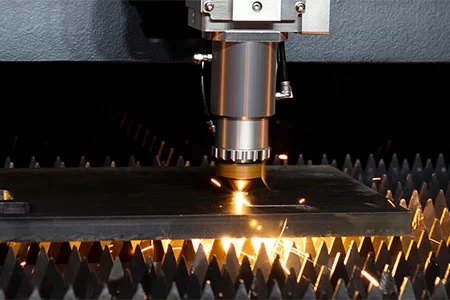

03Cutting

Cutting of metal sheets and edges of sheet metal spinning machines. We use laser cutting, which has smoother cuts and higher precision.

Quality Control Center

The quality control center can test the size, shape, mechanical properties and chemical properties of spun parts. We will formulate sampling inspection standards based on order quantity, qualification rate and other requirements.

-

Hardness Tester

Brinell and Rockwell hardness testers are used by sheet metal spinning factories to measure the hardness of products.

-

CMM

Its function is to detect the size and shape of sheet metal spinning parts.

-

Salt Spray Test Machine

Spinning plants use it to test the corrosion and oxidation resistance of metal parts.

-

Impact Tester

Used to determine the resistance of sheet metal spinning parts to high-speed loads under different environmental conditions.

-

Tensile Testing Machine

Complete various tests such as stretching, compression, bending, shearing, peeling, tearing, two-point extension, etc. of sheet metal spinning parts.

-

Spectrograph

It is an important tool for sheet metal spinning plants to detect material composition.

Steps of Sheet Metal Spinning Factory Complete Your Order

This is our service process. A simple introduction from solution development to after-sales service. Our service will be adjusted according to the needs of each customer but will only increase the content without increasing the price. You can contact us at any time to experience our service.

-

PART 01Custom A Suitable Solution

PART 01Custom A Suitable SolutionAfter receiving your request, our sales manager will communicate with you to understand your needs and lead the technical team to develop a solution that is more suitable for you. Ensure that the order qualification rate and delivery cycle can meet your requirements, and on this basis, reduce the price as much as possible.

-

PART 02Formulate a Quality Inspection Plan

PART 02Formulate a Quality Inspection PlanOur quality inspectors will formulate strict sampling standards based on the pass rate and performance requirements. The inspection content includes raw materials, semi-finished products, and finished products.

-

PART 03Molding

PART 03MoldingWe have close cooperation with mold manufacturers, which can obtain better quality and relatively low-priced molds. We will also choose more suitable mold materials according to the order size to further reduce the price of your purchase order.

-

PART 04Make Samples & Testing

PART 04Make Samples & TestingWe will complete the trial production of samples according to the preset process to ensure the consistency of the size and performance of all sheet metal spinning parts. We will send samples for you to test to unify the testing standards of both parties.

-

PART 05Raw Material Purchasing

PART 05Raw Material PurchasingAfter the samples pass the test, we will purchase the required materials from the raw material suppliers with whom we have close cooperation. If the quality is the same, the price will be lower.

-

PART 06Cutting or Blanking

PART 06Cutting or BlankingWe will choose the appropriate blanking method according to the quality of the sheet metal spinning parts. Both methods have their own advantages and disadvantages. Choosing the right one can reduce the production cost of the order.

-

PART 07Spinning

PART 07SpinningAfter the blank is placed on the spinning machine and fixed, the equipment will automatically run to complete the processing of the component.

-

PART 08Finishing

PART 08FinishingAfter the semi-finished product is completed, the spun parts need to be machined to complete the edge cutting, grinding, etc. to obtain the semi-finished products without heat treatment and surface treatment. Whether to perform heat treatment or not needs to consider the performance requirements of the sheet metal spun parts.

-

PART 09Surface Treatment

PART 09Surface TreatmentWe have several closely cooperating surface treatment factories to provide galvanizing, electrophoresis, powder coating, zinc plating, anodizing, polishing and other surface treatment requirements.

-

PART 10Packaging

PART 10PackagingWe support a full range of customized services including packaging materials, appearance, internal filling, etc.

-

PART 11Warehousing

PART 11WarehousingWe have a strictly managed warehouse that can provide temporary storage services for goods. We can deliver goods in one go or in batches according to your needs.

-

PART 12Delivery

PART 12DeliveryOur logistics center can quickly complete the transportation of goods in China. In terms of international logistics, we can find a more suitable freight company to complete the timely delivery of goods.

-

PART 13After Service

PART 13After ServiceAfter-sales service will solve your goods quality problems, and we provide return, exchange, and replenishment services. You can contact our sales manager after discovering the problem, and we will propose a solution that satisfies you.

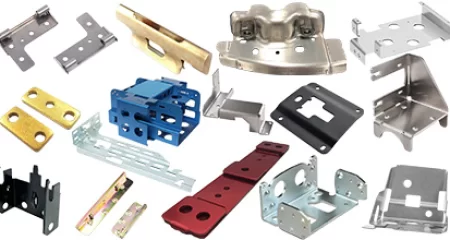

Sheet Metal Spinning Parts We Can Produce

We have currently provided sheet metal spinning manufacturing services for more than 20 industries including automobile manufacturing, furniture and home appliance manufacturing, general machinery manufacturing, etc. Our rich experience can better provide high-quality OEM services. We provide quality assurance services. We are always looking forward to your inquiries.

-

Sheet Metal Spinning Parts Factory In China

Sheet Metal Spinning Parts Factory In ChinaHULK Metal is committed to providing high-quality sheet metal spinning parts OEM services to customers around the world. We have an ISO 9001 certified factory and integrated supply chain.

READ MORE

-

Aluminum Stamping Parts Factory In China

Aluminum Stamping Parts Factory In ChinaHULK Metal is a well-known sheet metal parts manufacturer in China, which provides complete solutions to produce higher quality customized sheet metal parts at lower prices.

READ MORE

-

Precision Metal Stamping Parts Manufacturer

Precision Metal Stamping Parts ManufacturerHULK Metal's factory has passed ISO 9001 and ISO 16949 double certification, with rich experience in precision stamping parts production, and is one of the top suppliers in China.

READ MORE

-

OEM Auto Metal Stamping Parts Factory

OEM Auto Metal Stamping Parts FactoryOur factory is certified by ISO 9001 and ISO 16949. Our experienced technical team can develop a more complete solution according to the drawings and requirements.

READ MORE

-

Stamped Steel Parts Factory

Stamped Steel Parts FactoryStamped steel parts are made of carbon steel, alloy steel, and other plates into workpieces with specific shapes and functions using stamping processes such as blanking, bending, bulging, spinning, shrinking, flanging, etc.

READ MORE

-

China OEM Metal Stamping Parts

China OEM Metal Stamping PartsWe have abundant stamping factory resources and a complete supply chain to provide high-quality metal stamping parts OEM services. We have accumulated rich experience in OEM for hundreds of customers around the world and thousands of products.

READ MORE

More Results

You Will Get at HULK Metal

We have a professional team, ISO 9001 certified factory, and perfect supply to provide more comprehensive services. Through us, you can spend less energy, time and money to complete the procurement tasks again and again in China. We look forward to establishing long-term cooperation with you.

-

Get Higher Quality Sheet Metal Spinning Parts

Our sheet metal spinning factory is ISO 9001 certified. Our quality inspectors will strictly test the quality of raw materials, semi-finished products and finished products at each stage, and ensure the pass rate of the entire order by setting strict sampling standards. Advanced testing equipment enables us to produce higher precision spinning parts. We will also attach a complete test report to each order.

-

Get Goods Faster

We are a well-known sheet metal spinning factory in China. Our production capacity and efficiency are guaranteed. We can complete production faster through reasonable scheduling of equipment, employees, raw materials and other resources. Our logistics team can quickly complete the transportation of goods from the factory to the destination port. Our freight consulting team can help you find a more suitable international freight company. The goods can be delivered to you faster.

-

Spend Less Money

Our technical team will comprehensively consider the tolerance, complexity, surface accuracy, surface treatment and other requirements of sheet metal spinning parts by selecting the most appropriate production process and sequence to control order costs. We can minimize costs without affecting product quality. When you purchase more, we can also use a complete supply chain to save costs in terms of raw materials, packaging, warehousing logistics and cross-border freight. Contact us now to get a new quote.

-

Spend Less Time & Energy

Perfect service can help you save more energy and time. We have formed a full-service team including sales, technology, procurement, production, quality inspection, logistics, international freight company consulting and after-sales service to support you. They will become your office in China to help you handle all matters related to your order in China. We provide quality assurance services. After-sales service will handle the follow-up matters of your order for you.

Articles Of Sheet Metal Spinning Factory

This is the relevant content about sheet metal spinning that I have sorted out. If you need to know more, you can contact us at any time.

-

October 18, 2024

HULK Metal Fabrication

READ MORE

-

October 29, 2024

Introduction to Sheet Metal Forming: Processes, Materials, and Choosing the Right Partner

READ MORE

-

October 25, 2024

Comprehensive Guide to Sheet Metal Cutting: Methods, Materials, and Choosing the Right Partner

READ MORE

-

September 27, 2024

8 Types of Sheet Metal Assembly Technology and Their Processes and Applications

READ MORE