In addition to providing sheet metal raw material procurement, cutting, stamping, welding, machining, surface treatment, and assembly services, our sheet metal factory also provides packaging, warehousing, logistics, freight consulting, and after-sales se

To Supply Better Custom Sheet Metal Fabricaiton Service

HULK Metal Sheet Metal Factory

-

Introduction

-

Type

-

Served Industries

-

Benefits

-

Articles

-

Review

-

Top

Sheet metal manufacturing services are a process in which sheet metal factories process purchased aluminum, iron, copper, carbon steel, stainless steel, and other metal sheets by cutting, stamping, etc., and then undergo mechanical processing, surface treatment, and assembly to complete the finished product.

On this basis, we have also added technical support to better plan the above processes to save more time and money, added warehousing and logistics to manage the quantity and time of deliveries better, and added freight consulting teams to do Perfect handover of goods.

Our factory strictly implements ISO 9001 management. The factory has more automated production machines and experienced workers. The quality control center is equipped with complete testing instruments.

Kindly contact us. We will take you to visit the factory on-site or offline and develop solutions based on the drawings and requirements you provide and calculate a more affordable price.

Our Sheet Metal Factory

Below, we will introduce our sheet metal factory in terms of cutting, stamping, welding, etc. You can learn more about them here or contact us directly to visit the factory. You could feel our production capabilities more intuitively when choosing the second method.

-

Sheet Metal Stamping Factory

Sheet Metal Stamping FactoryOur sheet metal stamping factory has more than 20 punch presses of 300 tons, 250 tons, 160 tons, 120 tons, and other tonnages, which can complete the punching and forming of sheet metal parts of most thicknesses and sizes. We can help you specify a more cost-effective solution. Kindly contact us to get a quote.

Sheet Metal Stamping Factory

Sheet Metal Stamping FactoryOur sheet metal stamping factory has more than 20 punch presses of 300 tons, 250 tons, 160 tons, 120 tons, and other tonnages, which can complete the punching and forming of sheet metal parts of most thicknesses and sizes. We can help you specify a more cost-effective solution. Kindly contact us to get a quote.

READ MORE

-

Sheet Metal Welding Center

Sheet Metal Welding CenterHULK Metal has advanced arc welding, laser welding, gas welding, resistance welding, and other welding equipment. Experienced welders can complete welding with higher quality requirements.

Sheet Metal Welding Center

Sheet Metal Welding CenterHULK Metal has advanced arc welding, laser welding, gas welding, resistance welding, and other welding equipment. Experienced welders can complete welding with higher quality requirements.

READ MORE

-

Sheet Metal Cutting Center

Sheet Metal Cutting CenterWe have advanced CNC laser, plasma, and flame cutting machines. We can provide 0.1~45mm metal plate cutting services. The accuracy can reach ±0.05µm. Kindly contact us and send us drawings or samples. We will give you a more cost-effective solution.

Sheet Metal Cutting Center

Sheet Metal Cutting CenterWe have advanced CNC laser, plasma, and flame cutting machines. We can provide 0.1~45mm metal plate cutting services. The accuracy can reach ±0.05µm. Kindly contact us and send us drawings or samples. We will give you a more cost-effective solution.

READ MORE

-

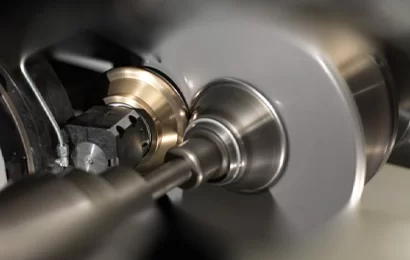

Sheet Metal Machining Factory

Sheet Metal Machining FactoryWe briefly introduce to you the equipment of our machining center in the form of pictures and text. Choosing more appropriate CNC processing equipment based on the complexity of the sheet metal structure can save more costs.

Sheet Metal Machining Factory

Sheet Metal Machining FactoryWe briefly introduce to you the equipment of our machining center in the form of pictures and text. Choosing more appropriate CNC processing equipment based on the complexity of the sheet metal structure can save more costs.

READ MORE

-

Sheet Metal Surface Treatment Factory

Sheet Metal Surface Treatment FactoryOur complete supply chain can provide electrophoresis, electroplating, hot dip plating, powder coating, passivation, anodizing, sandblasting, polishing, wire drawing, and other surface treatment services.

Sheet Metal Surface Treatment Factory

Sheet Metal Surface Treatment FactoryOur complete supply chain can provide electrophoresis, electroplating, hot dip plating, powder coating, passivation, anodizing, sandblasting, polishing, wire drawing, and other surface treatment services.

READ MORE

-

Sheet Metal Assembly Center

Sheet Metal Assembly CenterWe have advanced sheet metal assembly lines that can complete assembly, such as crimping, riveting, welding, and thread fastening. In addition, we can also provide higher standard cutting, stamping, and surface treatment services.

Sheet Metal Assembly Center

Sheet Metal Assembly CenterWe have advanced sheet metal assembly lines that can complete assembly, such as crimping, riveting, welding, and thread fastening. In addition, we can also provide higher standard cutting, stamping, and surface treatment services.

READ MORE

-

Sheet Metal QC Center

Sheet Metal QC CenterOur quality control center has a CMM, spectrometer, hardness tester, metallographic microscope, tensile tester, impact testing machine, salt spray tester, thickness gauge, and various measuring tools to complete the testing of various properties of sheet metal parts.

Sheet Metal QC Center

Sheet Metal QC CenterOur quality control center has a CMM, spectrometer, hardness tester, metallographic microscope, tensile tester, impact testing machine, salt spray tester, thickness gauge, and various measuring tools to complete the testing of various properties of sheet metal parts.

READ MORE

-

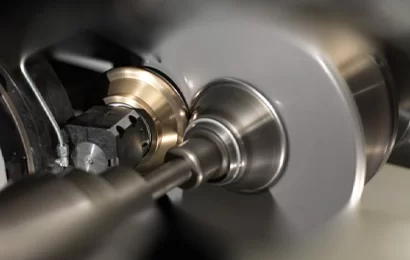

Sheet Metal Spinning Factory

Sheet Metal Spinning FactoryHULK Metal is one of the well-known sheet metal spinning factories in China, and has passed ISO 9001 certification. Since 2000, we have been committed to integrating a more complete supply chain to provide more thoughtful services to global customers.

Sheet Metal Spinning Factory

Sheet Metal Spinning FactoryHULK Metal is one of the well-known sheet metal spinning factories in China, and has passed ISO 9001 certification. Since 2000, we have been committed to integrating a more complete supply chain to provide more thoughtful services to global customers.

READ MORE

Industries HULK Metal Sheet Metal Factory Has Served

We have provided sheet metal manufacturing services for more than 20 industries, such as fitness equipment manufacturing, construction hardware, trailer manufacturing, and exterior decoration for cars, SUVs, Trucks, etc. You can send drawings to us. Our engineers will calculate a more competitive price for a comprehensive comparison.

-

Construction Hardware

Construction HardwareConstruction hardware is a variety of accessories produced using metal. What we will introduce to you here is to use sheet metal made of aluminum, iron, copper, steel, stainless steel, and other materials to complete the production of accessories through cutting, stamping, welding, machining, surface treatment, and other processes, and use riveting and thread fastening to complete the assembly. Construction hardware made later. Architectural hardware can be divided into links, supports, and fixations according to their uses during the sheet metal stamping process. Building hardware needs to undergo strict testing during production to meet usage requirements.

READ MORE

-

Metal Exterior Accessories for Car SUV Truck

Metal Exterior Accessories for Car SUV TruckWe have rich experience in sheet metal fabrication. ISO 9001-certified stamping factory, strict management quality control center, and thoughtful warehousing and logistics center provide complete services such as raw material procurement, production, quality inspection, packaging, warehousing, and logistics.

READ MORE

-

Trailer Parts

Trailer PartsWe can produce tire fenders, shock absorbers, support, trailer fences, metal connectors, frame couplers, and other trailer parts. Kindly tell us your needs and provide drawings, and we will give you a satisfactory price and solution.

READ MORE

-

Server Network Rack Cabint Accessories

Server Network Rack Cabint AccessoriesHULK Metal has a rich resource of sheet metal manufacturing factories in China, and can produce high-quality racks, cabinets, cable managements, brackets, trays, and other Server Network Rack Cabinet Accessories.

READ MORE

-

Metal Fabrication Parts

Metal Fabrication PartsWe have CNC laser cutting machines, advanced punching machines, bending equipment, welding machines, and assembly lines. We have helped hundreds of customers in more than 20 industries to complete the production of hundreds of metal fabrication parts.

READ MORE

More Results

Benefits Choose HULK Metal Sheet Metal Factory

We have provided sheet metal manufacturing services for more than 20 industries, such as fitness equipment manufacturing, construction hardware, trailer manufacturing, and exterior decoration for cars, SUVs, Trucks, etc. You can send drawings to us. Our engineers will calculate a more competitive price for a comprehensive comparison.

-

Shorter Lead Time

The technical team will quickly develop perfect solutions based on the drawings, samples, and special requirements you provide. IOS 9001-certified factories will use this to rationally arrange raw material procurement, production, and quality inspection processes. Experienced workers will operate advanced cutting, stamping, welding, and other equipment to complete each process efficiently. Your order can therefore be delivered faster.

-

Higher Quality

In order to provide higher quality products, we have developed a complete quality inspection process. We will test their physical and chemical properties to meet production requirements when purchasing raw materials. During the production process, we will randomly check the various properties of the semi-finished products in each process to ensure that they meet the requirements of the next process. After the finished product is completed, we will randomly check its appearance, tolerances, chemical properties, and various mechanical properties to meet the final use requirements. Each batch of orders comes with comprehensive material and finished product inspection reports.

-

Save More Time & Effort

We have established a professional service team to provide one-to-one service. They will solve your technical, raw material procurement, production, quality inspection, packaging, warehousing logistics, and other issues during your communication with us. The sales manager will take you to visit our sheet metal factory, provide you with real-time feedback on the progress of the order production, and assist you in completing each order. We'll help you think of things you haven't thought of. You only need to spend less energy and time when working with us.

-

Cheaper

We have established a professional service team to provide one-to-one service. They will solve your technical, raw material procurement, production, quality inspection, packaging, warehousing logistics, and other issues during your communication with us. The sales manager will take you to visit our sheet metal factory, provide you with real-time feedback on the progress of the order production, and assist you in completing each order. We'll help you think of things you haven't thought of. You only need to spend less energy and time when working with us.

Articles of Sheet Metal Factory

We have compiled some content on sheet metal fabrication. You can learn more about cutting, stamping, and welding, as well as how to choose a more suitable sheet metal factory here. You can try to contact us if you want to find an OEM factory. We have a special surprise for you.