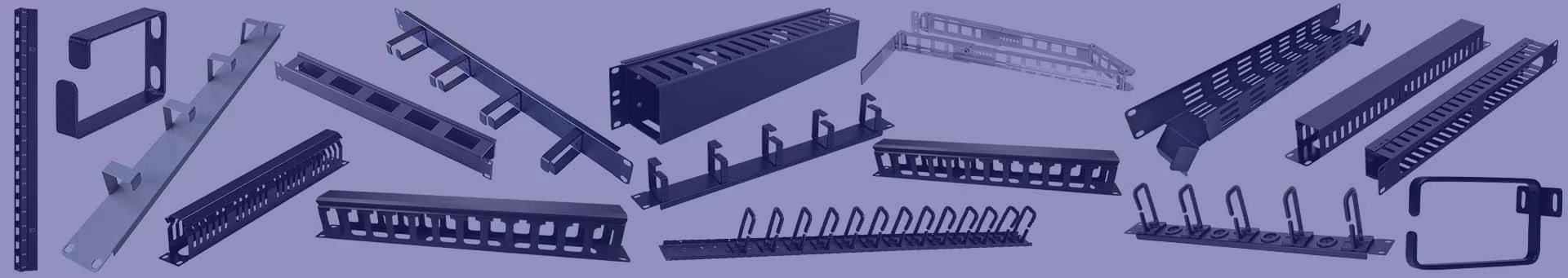

Processes of Complete Heavy Duty Network Server Cable Management:

Our comprehensive production process transforms your designs into premium Heavy Duty Network Server Cable Management solutions. Every phase—from initial planning and mold making to final packaging and aftersales—is executed with precision, ensuring superior quality and on-time delivery. Contact us now to begin your project journey.

Develop a Production Solution Based on the Drawings:

Based on your detailed drawings, our engineering team develops a production plan that addresses every design nuance. We analyze specifications, dimensions, and performance requirements to craft a strategy that ensures precision and efficiency throughout manufacturing. This plan outlines material selection, process workflows, and quality checkpoints. By anticipating potential challenges, we guarantee a seamless transition from design to production. Contact us today to discuss your project and experience our meticulous planning for outstanding Heavy Duty Network Server Cable Management solutions now.

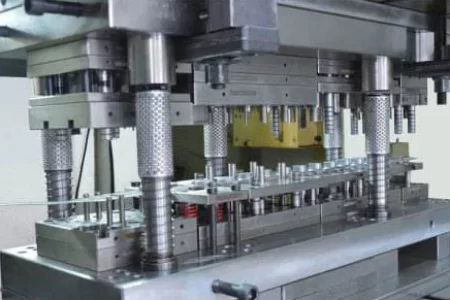

Mold Making:

Following the production plan, our technicians create custom molds matching your design. Using advanced CNC equipment, we fabricate molds that ensure accurate replication of each component. Our process includes quality checks and adjustments for flawless consistency. These molds are the foundation of our manufacturing, ensuring repeatable excellence. Trust our expertise to deliver molds that meet your specifications and boost production efficiency. Contact us to learn more about our mold-making capabilities for your Heavy Duty Network Server Cable Management project now.

Sample Trial Production and Adjustment:

After mold creation, we initiate sample trial production to validate design and process accuracy. Our quality team tests each sample for dimensional precision, finish quality, and performance under controlled conditions. Feedback from these trials refines both the mold and production parameters, ensuring optimal results. Adjustments guarantee that every sample meets your exact specifications before mass production begins. Contact us to discuss how our sample trial process can deliver outstanding Heavy Duty Network Server Cable Management solutions now for you immediately.

Quality Control Plan Establishment:

Our quality control team formulates a plan ensuring each production stage meets strict standards. We set inspection criteria, testing protocols, and corrective measures to maintain consistency and excellence. Each component is checked for accuracy, material integrity, and finish quality. This proactive approach minimizes defects and ensures reliable performance. Our quality plan is updated through regular audits. Trust our commitment to quality for your Heavy Duty Network Server Cable Management project. Contact us to learn about our quality control strategies now.

Production Scheduling:

Our production scheduling team coordinates every step to ensure timely project completion. We align machinery, workforce, and material deliveries to create an optimized timeline that minimizes downtime. Real-time monitoring and adjustments keep the process on track, meeting deadlines without compromising quality. Our scheduling integrates all production phases seamlessly, ensuring transparency and efficiency. Experience hassle-free manufacturing with punctual execution. Contact us today to learn how our scheduling can accelerate your Heavy Duty Network Server Cable Management project now for you.

Raw Material Procurement:

Our procurement team sources premium raw materials that meet your requirements for Heavy Duty Network Server Cable Management. We partner with trusted suppliers to secure metals and components of high quality. Each batch undergoes rigorous inspection to ensure compliance with performance and durability standards. This careful selection underpins our manufacturing, guaranteeing consistent excellence. Our efficient procurement minimizes delays and optimizes costs. Contact us today to discuss how our material sourcing can enhance your project now for exceptional results every time.

Laser Cutting:

Using precision cutting technology, our facility slices raw materials into exact dimensions for your Heavy Duty Network Server Cable Management. Automated systems and skilled operators ensure clean, accurate cuts with minimal waste. Each cut is verified for consistency, setting the stage for flawless processing. This process enhances product quality and efficiency. Our advanced equipment adapts to varying material types and thicknesses. Contact us today to learn how our cutting capabilities deliver superior performance in your cable management solutions now efficiently.

Bending:

In the bending phase, our advanced machinery shapes materials into precise curves and angles for your Heavy Duty Network Server Cable Management. Automated systems, overseen by skilled technicians, ensure every bend meets design specifications. This process guarantees structural integrity and a flawless finish while reducing waste. Our equipment adapts to varying material thicknesses for uniform results. Experience reliable, high-quality bending that enhances overall performance. Contact us today to learn how our bending process can optimize your cable management system now.

Stamping:

In the stamping stage, our high-speed equipment converts raw metal into precisely stamped components for your Heavy Duty Network Server Cable Management. Custom dies and controlled presses ensure every detail is consistent and accurate. This process produces clean, defined edges and strong structures critical for performance. Automated monitoring maintains quality and reduces waste. Our stamping operations deliver repeatable excellence for reliable assembly. Contact us today to learn how our stamping process can boost your cable management system now with precision.

Welding:

In the welding stage, precision joining techniques are employed to secure panel components with robust and seamless bonds. Our automated welding systems, combined with skilled oversight, ensure consistent heat control and alignment, resulting in durable joints that meet your custom design requirements. This process is essential for reinforcing the structural integrity of the panels, ensuring that all components are securely connected. Each weld undergoes strict inspection protocols to confirm its strength and quality. Our commitment to precision welding guarantees that the final product is not only aesthetically pleasing but also built to withstand the rigors of daily use in demanding environments. Contact us to learn more about our welding process.

Surface Treatment:

Following welding, our surface treatment process enhances the durability and appearance of your custom panels. Advanced techniques such as cleaning, polishing, and coating are employed to protect the metal from corrosion and wear. Automated application systems ensure a uniform finish across every panel, while quality checks verify the smoothness and consistency of the treatment. This stage not only improves the product's visual appeal but also extends its lifespan, ensuring it remains functional and attractive over time. Our surface treatment process is tailored to meet your specific requirements, offering both protection and aesthetic value. Reach out to us today to discuss how our surface treatment capabilities can elevate your project.

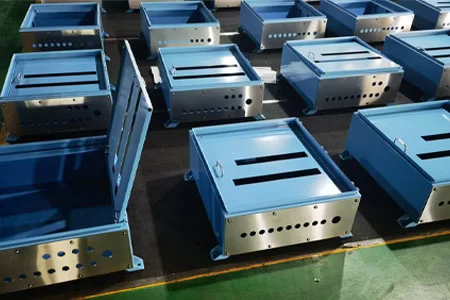

Assembly:

In the assembly phase, our technicians integrate all components into a cohesive Heavy Duty Network Server Cable Management system. Automated lines and manual precision ensure each part fits perfectly and functions correctly. Inspections verify structural integrity and performance. This coordinated process produces a reliable, ready-to-install product meeting your specifications. Experience seamless assembly that boosts efficiency and quality. Contact us today to discover how our assembly process can bring your cable management solution to life now for outstanding overall industry performance.

Packaging & Delivery:

After assembly, our packaging team prepares each Heavy Duty Network Server Cable Management unit for shipment. Using automated wrapping and secure sealing, we protect products from damage during transit. Custom packaging prevents moisture, dust, and impact, ensuring units arrive in pristine condition. Every package is inspected for quality. Our efficient process minimizes handling while maintaining integrity. Contact us today to learn how our packaging services provide the final safeguard for your cable management system now, ensuring safe delivery always, guaranteed.

After-sales Service:

Our aftersales service focuses on returns, exchanges, and replenishment for your Heavy Duty Network Server Cable Management products. If you encounter any issues upon delivery, we offer a streamlined process for returns or exchanges to ensure complete satisfaction. Our team is dedicated to providing additional stock when needed, maintaining your supply continuity. We do not offer repair or system assembly services. Trust our responsive aftersales support to address your needs quickly. Contact us today to discuss our aftersales process now.