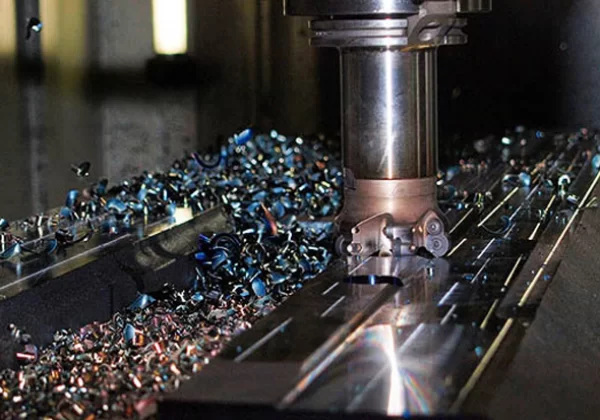

We will use CNC machining centers to optimize the appearance, size, surface accuracy, and other aspects of the stamped, cut, and welded sheet metal parts. We also use it for direct sheet metal fabrication services when necessary.

Advanced CNC Machining Center

Supply Better Sheet Metal Machining Service

-

Capacities

-

Industries

-

Introduction

-

Factory

-

Benefits

-

Process

-

Articles

-

Review

-

Top

Sheet Metal Machining Service Capacities

Sheet metal processing is mainly used to supplement the structure of parts that cannot be completed using cutting, welding, stamping, and other processes. CNC machining centers play an irreplaceable role in sheet metal manufacturing that other processes cannot replace. Kindly contact us to learn more.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron, Aluminum, Steel, Brass, Stainless Steel |

PROCESS: | Turning, Milling, Grinding, Drilling, Reaming, Tapping, Polishing, And So On. |

Thickness: | <=50cm/piece / According to Drawings |

Length*Width | <=1m*1m/piece / According to Drawings |

PRODUCTION CAPACITY: | 500 tons/month |

CERTIFICATION: | ISO 9001 |

TOLERANCE LEVEL: | Min IT5, According to CNC Machining Process. |

SURFACE ROUGHNESS: | RA>=0.2µm |

MACHINING CENTER: | Four-axis, Five-axis, Three-axis. |

MOQ: | 500KG / A Standard Tray |

Sheet Metal Machining Introduction

We have compiled some knowledge aspects of sheet metal processing so that you can understand it from more perspectives. When we also have rich experience, we can accurately find the right sheet metal manufacturing factory to complete the order at a lower cost, with less time and managers.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Choose HULK Metal as Sheet Metal Machining Factory

When we receive your order, a team including technology, procurement, production, quality inspection, sales, and after-sales will provide one-to-one service. They will work together to help you solve the problems you encounter during the purchasing process. Kindly contact us. We will take you to experience different purchasing.

-

Factory

Our sheet metal manufacturing plant has an ISO 9001 management process. Advanced laser cutting machines and punching machines can complete the process before the mechanical processing of sheet metal machines. We use a variety of machining machines to reasonably arrange production according to order conditions to improve efficiency, shorten lead time, and reduce costs.

-

Experience

We have produced thousands of products for hundreds of sheet metal buyers, covering more than 20 industries, including automobile exterior decoration, fitness equipment production, trailer manufacturing, and construction hardware. After more than 20 years of development, we have integrated global freight channels, covering almost all routes by sea, land, and air. Our experienced technical team can leverage our mature supply chain to develop excellent solutions. Kindly contact us to obtain.

-

Quality

We care about product quality as much as you do. To this end, we have established a well-equipped quality inspection center that can provide testing of physical and chemical properties of materials, mechanical properties, corrosion resistance, size, shape, and surface accuracy of finished products. We will attach material and product testing reports to batches of orders. We also pay attention to the quality of service because high-quality service quality can help you save more energy and time costs.

-

Service

We have established a complete service team to solve the raw material procurement, production, quality inspection, and other problems you may encounter when purchasing. The sales manager who is in contact with you will provide full feedback on the production progress of the order. Quality assurance services will be provided to you after the order is delivered. We have established a service quality supervision hotline. You can give feedback to our CEO at any time.

Machining Processes of Your Sheet Metal Parts

Here, we mainly introduce how sheet metal manufacturing plants perform mechanical processing. Here is only a brief description of it. You can contact us for more information.

-

01Sheet Metal Parts Leave Machining Allowance

01Sheet Metal Parts Leave Machining AllowanceSheet metal parts that require metal processing need to leave enough machining allowance to ensure that the dimensions meet the final requirements.

-

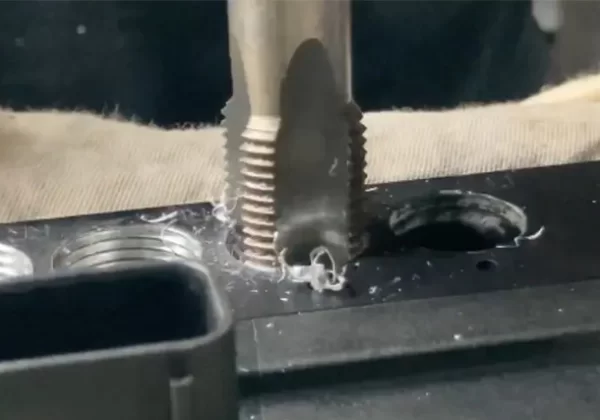

02Choose the Right Machine

02Choose the Right MachineFor small batch orders and sheet metal parts with uncomplicated structures, we will use ordinary processing machine tools to process the holes, threads, and edges of the sheet metal parts. We will use CNC machining centers to complete complex sheet metal parts. The suitable process can save costs in many aspects, such as labor, materials, time, etc.

-

03Formulate Machining Routes

03Formulate Machining RoutesWhen we process complex metal parts, we need to consider the processing process, which can save the number of changes of equipment, tools, and procedures to improve order production efficiency and sheet metal parts' repeatability.

-

04Design Machining Program

04Design Machining ProgramFor sheet metal parts using CNC machining centers, we need to set up the program in advance according to the drawings and import it into the control center. In actual production, it is only necessary to change the program according to the next processing position.

-

05Fixing Sheet Metal Parts

05Fixing Sheet Metal PartsThe fixed surface and position are determined according to the number of axes of the CNC machining center and the complexity of the sheet metal parts. To complete processing faster.

-

06Machining

06MachiningUse the appropriate tool to start machining the sheet metal parts according to the set procedures and steps. Pay attention to protection during processing.

-

07Quality Control

07Quality ControlQuality control mainly tests the accuracy, shape, performance, and other dimensions of sheet metal parts. Our quality inspection team will develop a complete quality inspection plan according to customer requirements.

-

08Packaging

08PackagingWe provide customized services for packaging materials, appearance, and packaging methods. We work closely with packaging factories and can get prices you can't get.

-

09Delivery

09DeliveryWe provide short-term warehousing, logistics, and cross-border freight consulting services. Help you plan a more suitable freight route.