Our quality control center has a CMM, spectrometer, hardness tester, metallographic microscope, tensile tester, impact testing machine, salt spray tester, thickness gauge, and various measuring tools to complete the testing of various properties of sheet

To Manufacture Better Sheet Metal Parts

HULK Metal Sheet Metal QC Center

-

Introduction

-

Equipment

-

Moments

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

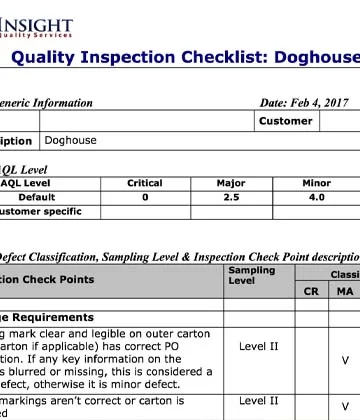

Experienced quality inspection personnel will develop complete inspection solutions based on finished product requirements. They can skillfully operate various testing instruments to conduct strict testing on the physical and chemical properties of raw materials, sheet metal parts tolerances, shape, tensile strength, shear resistance, torsion resistance, impact resistance, hardness, surface quality, and other aspects. Before the raw materials are put into order production, the quality control center will complete various physical and chemical property tests to meet production requirements. Sheet metal parts undergo strict random inspection before leaving the factory to ensure that the qualification rate of each batch of orders meets the requirements.

HULK METAL QC Center Equipment

One of the reasons we can provide high-quality sheet metal parts is that we have advanced inspection equipment. Our testing equipment is shown here. You can contact us to visit the factory online for free. Our sales manager will introduce you to the function of each instrument in detail.

-

01CMM

It can measure the three-dimensional dimensions of sheet metal parts. Its measurement accuracy is 1~3μm, and it can measure shape and tolerance at the same time.

-

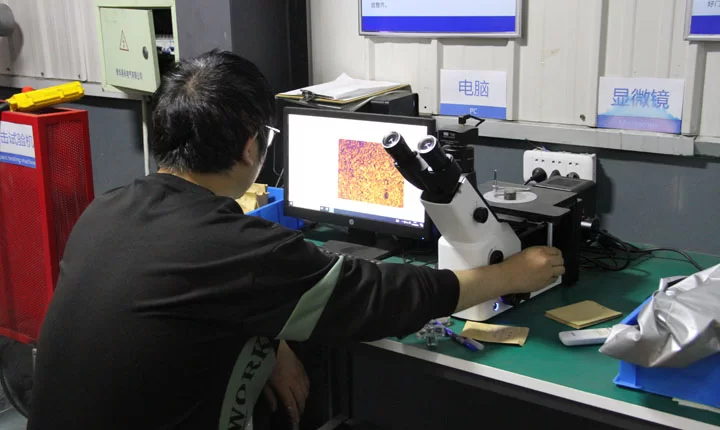

02Electron Microscope

It can be used to detect the internal structure of raw materials and check whether their performance meets production requirements.

-

03Hardness Tester

There are two types of Brinell hardness tester and Rockwell hardness tester. They can test the hardness of sheet metal parts to determine their wear resistance.

-

04Impact Tester

We use it to measure the resistance of sheet metal parts to high-speed loads under different environments.

-

05Spectrograph

Detect the types and contents of elements in metal plates.

-

06Salt Spray Test Machine

Place the surface-treated sheet metal parts in a simulated environment to test their oxidation resistance, corrosion resistance, etc.

-

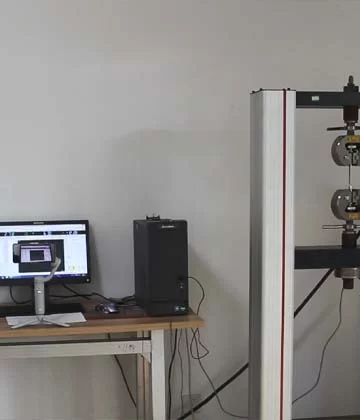

07Tensile Testing Machine

The tensile, fracture, compression, bending, shearing, bending resistance, and other properties of sheet metal parts can be tested through a variety of experiments.

Quality Control Center Testing Moment

Our quality inspection team is one of the reasons why we can provide higher-quality sheet metal parts. They can skillfully operate various equipment to complete product testing. Kindly contact us to view their testing details.

-

Corrosion and Oxidation Resistance Testing

Use a salt spray testing machine to simulate the use environment to test the corrosion resistance and oxidation resistance of sheet metal parts or surface treatments.

-

Casting Dimensional Inspection

Use a three-dimensional coordinate measuring machine to check whether the product size and shape are qualified.

-

Hardness Testing

Use a Rockwell or Brinell hardness tester to test the hardness of sheet metal parts.

-

Metallographic Testing

Quality inspectors operate electron microscopes to examine the internal structure of metal.

-

Tension Testing

Use a tensile testing machine to test the tensile, fracture, and yield resistance of sheet metal parts.

How HULK Metal QC Center Test Your Order

This is one of the three reasons why we can provide you with higher-quality sheet metal parts. The experienced team will develop a more appropriate testing plan based on the order quantity. We will develop a more appropriate sampling plan to ensure that the test pass rate is the order pass rate. Kindly contact us to learn more.

-

PART 01Raw Material Testing and Report

PART 01Raw Material Testing and ReportThe raw materials of each batch of orders will undergo strict physical and chemical property testing before being put into use to meet the requirements of order production. We eliminate the appearance of substandard products from the source.

-

PART 02Semi-Finished Product Sampling Inspection

PART 02Semi-Finished Product Sampling InspectionSampling inspection of semi-finished products obtained from each process to eliminate substandard parts from the production process. The finished product qualification rate obtained in this way will be maximized.

-

PART 03Finished Sheet Metal Parts Testing

PART 03Finished Sheet Metal Parts TestingExperienced quality inspection personnel use advanced testing instruments to complete various performance tests of sheet metal parts.

-

PART 04Goods Quantity Testing

PART 04Goods Quantity TestingFor large quantity orders, we estimate the quantity of goods by dividing the total weight by the weight of the individual items. The quantity of goods in each order will exceed the requirements.

-

PART 05Pre-delivery Texting

PART 05Pre-delivery TextingWe will unpack the products again to randomly check the quality and recalculate the quantity to ensure that customers receive goods with guaranteed quality and quantity.

-

PART 06Issuing a Test Report

PART 06Issuing a Test ReportWe will issue a complete quality inspection report for each batch of orders.

Sheet Metal Parts We Have Produced

Here, we produce construction hardware, fitness equipment parts, automotive exterior trim accessories, and custom sheet metal parts for other industries. You can send drawings to us to get more suitable solutions and quotations.

-

Trailer Tow Hitch Drop Plate Factory in China

Trailer Tow Hitch Drop Plate Factory in ChinaOur OEM Trailer Tow Hitch Drop Plate is generally made of high-performance carbon steel, which can withstand the weight and stress during towing. The finished product needs to pass strict random inspections to ensure the qualified rate.

READ MORE

-

Winch Post for Boat Trailer Factory in China

Winch Post for Boat Trailer Factory in ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Tire Carrier Factory In China

Trailer Tire Carrier Factory In ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Support Legs Factory in China

Trailer Support Legs Factory in ChinaWe have a complete trailer support legs supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide.

READ MORE

-

Trailer Stake Pocket Manufacturer In China

Trailer Stake Pocket Manufacturer In ChinaHULK Metal is dedicated to providing excellent trailer stake pocket manufacturing services to numerous suppliers. We have an experienced technical team, an ISO 9001 and ISO 16949 certified sheet metal factory, and supporting logistics.

READ MORE

-

Trailer Hitch Mount Factory in China

Trailer Hitch Mount Factory in ChinaWe have a sheet metal manufacturing facility certified by ISO 9001 and ISO 16949, capable of providing high-quality OEM services for your trailer hitch mounts. Our integrated supply chain ensures the efficient completion of every order.

READ MORE

-

Trailer Coupler Factory In China

Trailer Coupler Factory In ChinaWe have an advanced sheet metal factory certified by ISO 9001 and ISO 16949 to meet your trailer coupler manufacturing needs. We provide customers with quality services through perfect supply chain management.

READ MORE

-

Boat Trailer Bunk Brackets Factory in China

Boat Trailer Bunk Brackets Factory in ChinaWe can use this component to construct a "V" structure on the trailer to secure the boat. It consists of three primary parts: the trailer connection, the support rod, and the support head.

READ MORE

-

Pickup Truck Bed Accessories OEM Factory

Pickup Truck Bed Accessories OEM FactoryWe have a complete pickup truck bed accessories supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide. We provide a complete QA Service.

READ MORE

-

Cargo Baskets

Cargo BasketsIt is a storage expansion placed on the roof of SUVs, Cars, or Trucks, used to store and fix luggage, tents, sports tools, and other facilities that cannot be placed inside the car.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesWe can produce a full range of Spread Anchors, wire loop boxes concrete embeds, and other precast concrete accessories produced using cutting, stamping, welding, and other processes.

READ MORE

-

Post to Beam Connector

Post to Beam ConnectorHULK Metal focuses on providing high-quality sheet metal manufacturing services to global sheet metal purchasers. So far, we have produced millions of items of more than a dozen types for customers.

READ MORE

-

Metal Base Plate

Metal Base PlateHULK Metal has an ISO 9001-certified factory. We can develop complete production and quality inspection plans to provide high-quality metal base plate OEM services according to your requirements.

READ MORE

More Results

Choose HULK Metal You Will Get

HULK Metal has a complete supply chain to provide excellent sheet metal parts foundry services. Below are the benefits you will get, when choosing HULK Metal as your foundry.

-

Get Higher Quality Sheet Metal Parts

An ISO 9001-certified sheet metal manufacturing plant, advanced equipment, experienced workers, and a fully equipped quality control center are the basis for our ability to provide high-quality sheet metal parts. We will develop a complete testing process based on your requirements. Each batch of orders will be accompanied by a comprehensive finished product quality inspection report and material report.

-

Get Goods Faster

Our technical team will plan a more reasonable production process according to your requirements. Experienced workers can ensure that all production links are carried out more efficiently. Our logistics center can realize the seamless connection of sheet metal parts from factory to factory, factory to warehouse, and warehouse to port. You can also find more suitable routes for faster delivery of your goods through our Freight Advisory Center.

-

Spend Less Money

Our complete supply chain can achieve all-round cost reduction and efficiency increase in raw material procurement, mold manufacturing, production, packaging, transportation, and other aspects to a greater extent. The increase in the demand for sheet metal parts can maintain the supply chain operating efficiently for a long time. This means that you can spend less money to complete goods that other companies cannot provide.

-

Spend Less Time & Energy

We hope to help you save more time and energy through comprehensive services. To this end, we have launched a series of services such as online factory visits, online follow-up of order production, real-time feedback on sheet metal production progress, and real-time feedback on cargo transportation status. You can keep track of the progress of your order without being physically present.

Articles of Sheet Metal Parts

We have compiled some content on quality control of sheet metal parts. You can tell how familiar we are in this industry. You can send drawings and requirements to us when OEM is needed. Our sales manager will lead the team to provide one-to-one service.