HULK Metal has advanced sheet metal cutting, stamping, welding, machining factories, and quality control centers, with experienced technology, production, and quality inspection teams. We also have a complete supply chain to complete your orders faster and better at lower prices.

Supply Precision Cutting Stamping Welding Service

REQUEST A QUOTE

HULK METAL Strengthen

Three-dimensionally integrate the supply chain to provide more complete sheet metal fabrication services. Advanced punching, bending, spinning, drawing, flanging, shrinking, and other processes can process various parts. Processes such as welding, machining, surface treatment, and assembly meet the various needs of customers. High-quality service makes your purchase easier.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Get Better Solutions

Three-dimensionally integrate the supply chain to provide more complete sheet metal fabrication services. Advanced punching, bending, spinning, drawing, flanging, shrinking, and other processes can process various parts. Processes such as welding, machining, surface treatment, and assembly meet the various needs of customers. High-quality service makes your purchase easier.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Types of Sheet Metal Fabrication Service

HULK METAL can provide almost all sheet metal stamping, welding, cutting, machining, assembly, and surface treatment services. Click here to learn more, or contact us directly for solutions and quotes.

-

Surface Treatment

ServiceIn sheet metal fabrication, surface treatment is a very important process in finishing. The surface properties of parts are improved through galvanizing, electrophoresis, anodizing, and powder spraying to extend their service life in the use environment. Surface quality is mainly coating thickness, hardness, accuracy, and life in the use environment. The testing tools are thickness gauge, hardness tester, and salt spray tester. Professional surface treatment factories can better complete orders in a shorter time according to requirements.

READ MORE

-

Metal Machining

ServiceMachining services mainly play the role of processing holes and threads, cutting shapes, and adjusting shapes in sheet metal fabrication services. Hole processing processes include drilling, reaming, milling, thread processing includes tapping, milling, turning, and cutting processes include laser cutting, plasma cutting, flame cutting, water cutting, etc. Our technical team will arrange a more suitable machining process based on the drawings and samples you provide. Kindly contact us for solutions and quotes.

READ MORE

-

Metal Welding

ServiceWelding is a very critical process in sheet metal fabrication. The stamped and machined semi-finished products are welded into the required parts. Choose the appropriate welding process and get better performance from the welding joint. There are many ways to classify welding processes. The welding types include arc welding, gas welding, resistance welding, laser welding, etc. Like the sheet metal stamping process, choosing the suitable welding process can complete parts faster, reduce production costs, and shorten order time.

READ MORE

-

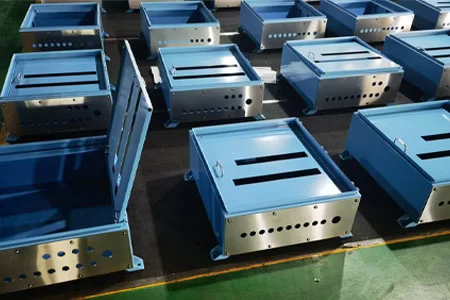

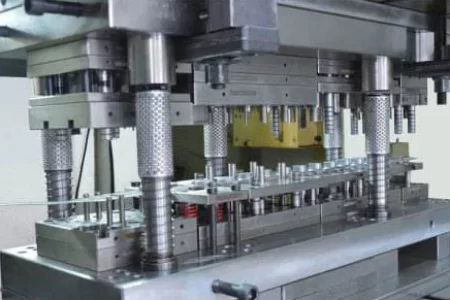

Metal Stamping

ServiceSheet metal stamping is one of the most basic and critical sheet metal fabrication services. It uses punches and dies to process iron, steel, copper, aluminum, and other metal sheets into the required parts through punching, spinning, bending, deep drawing, drawing, expanding, flanging, and shrinking. Complex parts often need a combination of processes to complete. A high-quality sheet metal fabrication service provider can plan a more reasonable metal stamping process to improve the yield rate, shorten order production time, and save materials, labor, and other costs.

READ MORE

-

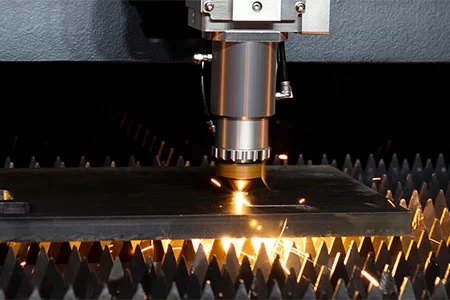

Metal Cutting

ServiceWe use laser cutting for most of our metal cutting services. The finer slits of laser cutting can save more material costs, and the smoother cutting edges can save machining costs. CNC cutting equipment can improve cutting efficiency and the repeatability of sheet metal cutting parts. We use plasma cutting when the thickness of the metal plate exceeds 30cm. For small batch orders, we use flame cutting. Choosing the appropriate cutting method can not only shorten order delivery time but also reduce costs.

READ MORE

You only need to provide drawings, and we will formulate solutions, calculate prices, and complete orders until delivery.

HULK METAL To Be

The Top Metal Fabricator

Since 2000, HULK Metal (Qingdao Hulk Metal Technology Co., Ltd) has begun to focus on providing metal processing services to global customers. The business scope covers metal casting, metal forging, and metal fabrication. We will treat metal fabrication services as an independent team in 2021 to provide better services. We have reintegrated the resources of ISO 9001-certified stamping, welding, machining, and surface treatment factories to improve the quality of orders, shorten lead time, and reduce costs. Our complete logistics and freight consulting team can perfectly connect orders and freight on time. Every order can be delivered to you faster.

Give HULK Metal a chance, and let us achieve mutual success.

REQUEST A QUOTE

Foundry Show

Industries We Served

We have provided OEM services for over 20 industries, such as automotive exterior accessories, trailers, fitness equipment, and construction. Our technical team will develop a complete production solution based on the samples or drawings you provide and strive to complete your order at a more competitive price.

-

Construction Hardware

Construction HardwareConstruction hardware is a variety of accessories produced using metal. What we will introduce to you here is to use sheet metal made of aluminum, iron, copper, steel, stainless steel, and other materials to complete the production of accessories through cutting, stamping, welding, machining, surface treatment, and other processes, and use riveting and thread fastening to complete the assembly. Construction hardware made later. Architectural hardware can be divided into links, supports, and fixations according to their uses during the sheet metal stamping process. Building hardware needs to undergo strict testing during production to meet usage requirements.

READ MORE

-

Metal Exterior Accessories for Car SUV Truck

Metal Exterior Accessories for Car SUV TruckWe have rich experience in sheet metal fabrication. ISO 9001-certified stamping factory, strict management quality control center, and thoughtful warehousing and logistics center provide complete services such as raw material procurement, production, quality inspection, packaging, warehousing, and logistics.

READ MORE

-

Trailer Parts

Trailer PartsWe can produce tire fenders, shock absorbers, support, trailer fences, metal connectors, frame couplers, and other trailer parts. Kindly tell us your needs and provide drawings, and we will give you a satisfactory price and solution.

READ MORE

-

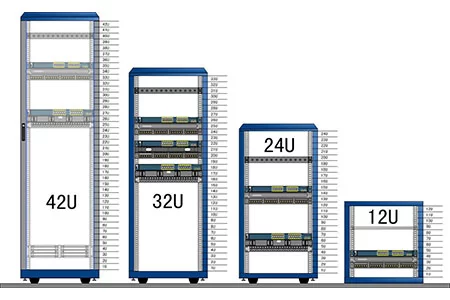

Server Network Rack Cabint Accessories

Server Network Rack Cabint AccessoriesHULK Metal has a rich resource of sheet metal manufacturing factories in China, and can produce high-quality racks, cabinets, cable managements, brackets, trays, and other Server Network Rack Cabinet Accessories.

READ MORE

-

Metal Fabrication Parts

Metal Fabrication PartsWe have CNC laser cutting machines, advanced punching machines, bending equipment, welding machines, and assembly lines. We have helped hundreds of customers in more than 20 industries to complete the production of hundreds of metal fabrication parts.

READ MORE

More Results

You only need to provide drawings, and we will formulate solutions, calculate prices, and complete orders until delivery.

Sheet Metal Fabrication News

We have organized content related to sheet metal fabrication, including types, applications, advantages and disadvantages of metal stamping, types, applications, advantages and disadvantages of welding, etc. You can find what you need here. Kindly contact us if you want to know more or have a parts order.

- News

- Technology

-

February 28, 2025

A Suitable OEM Factory for Your Network Server Blank Panels

READ MORE

-

February 28, 2025

Common Network Server Accessories: A Complete Guide

READ MORE

-

February 28, 2025

Network Server Tray Solutions for Enhanced Data Center Efficiency

READ MORE

-

February 26, 2025

A Comprehensive Guide to Network Server Racks

READ MORE

-

February 24, 2025

Optimized Network Server Tray Solutions for Enhanced Data Center Efficiency

READ MORE

-

February 24, 2025

Superior Network Server Cable Management Solutions by HULK Metal

READ MORE

-

February 21, 2025

Optimized Network Server Blank Panel Solutions for Modern Data Centers

READ MORE

-

February 21, 2025

Choose a Suitable OEM Factory to Produce Your Network Server Racks

READ MORE

-

February 21, 2025

1U, 2U 18U, 42U, What That Mean

READ MORE

-

February 21, 2025

How Should You Choose A Suitable OEM Factory to Produce Your Network Server Accessories

READ MORE

-

December 04, 2024

Comprehensive Guide to Sheet Metal Spinning

READ MORE

-

October 29, 2024

Introduction to Sheet Metal Forming: Processes, Materials, and Choosing the Right Partner

READ MORE

-

October 25, 2024

Comprehensive Guide to Sheet Metal Cutting: Methods, Materials, and Choosing the Right Partner

READ MORE

-

October 24, 2024

Comprehensive Guide to Sheet Metal Blanking

READ MORE

-

September 30, 2024

Comprehensive Understanding of Sheet Metal Welding

READ MORE

-

September 27, 2024

8 Types of Sheet Metal Assembly Technology and Their Processes and Applications

READ MORE

-

September 24, 2024

The Most Comprehensive Introduction To Metal Stamping Dies

READ MORE

-

September 19, 2024

Introduction to Metal Stamping Processes

READ MORE

Frequently Asked Questions

Here is a collection of sheet metal fabrication-related questions that customers have asked and some of our standard answers. Our service content can also be seen here. Kindly contact us for complete solutions and quotes.

-

Sheet Metal manufacturing is also called Sheet Metal Fabrication. It is a process in which factories use cutting or stamping to process aluminum, iron, steel, copper, or other metal sheets and strips into blanks of specific size and then process them into sheet metal parts or finished products with specific shapes and properties through forming, welding, riveting and other processes.

-

Many customers do not have drawings when they first cooperate with us, and they choose to send us samples. We develop production solutions based on the size and weight of the sample. After cooperation, our engineers helped them draw 2D drawings and 3D drawings. And because of our excellent product quality, excellent service, and suitable prices, they have been cooperating with us.

You can first send us product pictures, required quantities, and other information, and our sales manager will communicate other details with you.

-

We can provide electro-galvanizing, hot-dip galvanizing, powder coating, electrophoresis, phosphating, bluing, and other surface treatments.

Aluminum sheet metal parts can be anodized.

We can also provide polishing, brushing, and other treatments for stainless steel sheet metal parts.

You can contact us for complete surface treatment solutions and quotes.

-

The smallest tolerance we can achieve is 0.05µm. However, this needs to be achieved with the help of mechanical processing technology. Because ordinary stamping, cutting, and welding processes are difficult to meet such strict tolerance requirements.

-

We have more than a dozen customers who thought the price was too expensive and did not cooperate with us after receiving our samples. However, they came back to us a few months later for cooperation. Today, we still maintain a close cooperative relationship. Products that are too cheap may bring problems of sub-standard quality. So please be sure to choose carefully.

-

Hello!

QINGDAO HULK METAL Technology Co., ltd (hereinafter referred to as "we") takes your privacy and personal information very seriously and is always committed to protecting your privacy. In order for you to better enjoy the services provided by HULK Metal, we have specially formulated this privacy policy, and we hope to explain to you what information we collect when you use HULK Metal's services and how to collect, use, and protect this information.

-

To be precise, welding is an important process in the Metal Fabrication process. Its function is to melt the connecting parts of two parts and connect them. Metal Fabrication is the process of using various processes to change the size and shape of sheet metal, profiles, etc., and then assemble them into a more complex part.

-

The only common process for sheet metal manufacturing is to use cutting to cut the material to a specific size, and then change its shape through a complex process to obtain the final workpiece. The reason for calling it a universal process is that the production process will be determined based on the complexity of the sheet metal parts and cannot be generalized. Below we will introduce in detail:

-

Sheet metal fabrication service is a process in which factories or companies cut, stamp, weld, and assemble processing metal sheets according to requirements and finally complete the order. In industrial production, ODM is designing drawings and finally completes production, while OEM is only completing production based on drawings. Here we will give you a detailed introduction to sheet metal processing service types, materials, and supplier selection.

-

Sheet metal fabrication is a process in which we use shearing, stamping, welding, and other tools to complete cutting, deformation, and assembly to obtain a workpiece that can solve various problems. Materials, and procedures, will be described in detail below. Kindly send drawings to us if you need a sheet metal manufacturer to OEM your product.