Processes of Complete Wall Mount Network Rack:

Our comprehensive production process converts your designs into superior Wall Mount Network Racks. Each phase—from initial planning and mold making to final packaging and aftersales—is executed with precision and rigorous quality control. Contact us now to initiate your project journey.

Develop a Production Solution Based on the Drawings:

Based on your detailed drawings, our engineering team develops a robust production plan addressing every design nuance. We analyze dimensions, material specifications, and performance requirements to craft a strategy that ensures precision throughout manufacturing. This plan outlines optimal material selection, workflow procedures, and critical quality checkpoints. By foreseeing potential challenges, we guarantee a seamless transition from design to production. Reach out today to discuss your project requirements and experience our meticulous planning for flawless Wall Mount Network Rack solutions.

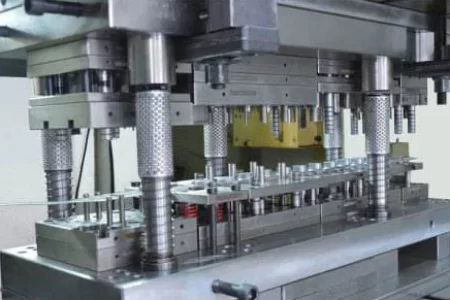

Mold Making:

Following the production plan, our technicians fabricate custom molds that mirror your design specifications with utmost accuracy. Utilizing advanced CNC equipment, we produce molds that ensure consistent replication of every component. Our process involves stringent quality inspections and fine-tuning to achieve flawless precision. These molds serve as the foundation for high-volume production, ensuring repeatability and superior product quality. Contact us to discover how our mold-making expertise enhances your Wall Mount Network Rack manufacturing process.

Sample Trial Production and Adjustment:

After mold fabrication, we initiate a sample trial phase to validate design integrity and production efficiency. Our quality team rigorously tests initial samples for dimensional accuracy, surface finish, and overall performance under simulated conditions. Feedback is used to make necessary adjustments to both mold and process parameters, ensuring the final product meets your exact specifications. This iterative process is crucial for minimizing defects and ensuring reliable performance. Contact us today to experience our commitment to precision in every Wall Mount Network Rack we produce.

Quality Control Plan Establishment:

Our dedicated quality control team develops a comprehensive plan that governs every production stage. This plan establishes stringent inspection criteria, testing protocols, and corrective actions to guarantee consistent product excellence. Each component is verified for material integrity, dimensional accuracy, and finish quality. Regular audits and real-time monitoring ensure that any deviations are promptly addressed. With our proactive quality management approach, we deliver Wall Mount Network Racks that exceed expectations. Reach out now to learn how our quality plan reinforces your project's success.

Production Scheduling:

Our production scheduling team meticulously coordinates every manufacturing phase to meet your project deadlines. By aligning machine availability, labor shifts, and material deliveries, we create an optimized timeline that minimizes downtime and enhances efficiency. Real-time tracking enables us to adjust schedules dynamically, ensuring seamless workflow integration. This systematic approach guarantees timely completion of your Wall Mount Network Rack production without compromising quality. Contact us today to experience the benefits of our efficient scheduling system.

Raw Material Procurement:

Our procurement team sources only premium raw materials that meet your specifications for durability and performance. We collaborate with trusted suppliers to secure high-quality metals and components, which undergo rigorous inspection upon arrival. This careful selection process ensures consistency and reliability throughout production. By streamlining material procurement, we reduce delays and optimize overall costs. Trust our expertise to provide the foundation for exceptional Wall Mount Network Racks. Contact us now to discuss how our sourcing strategy benefits your project.

Laser Cutting:

Utilizing precision cutting technology, our facility slices raw materials into exact dimensions required for your Wall Mount Network Rack. Automated systems combined with skilled operators guarantee clean, accurate cuts with minimal waste. Each cut is verified through real-time digital controls to maintain strict tolerances. This step lays the groundwork for flawless subsequent processing and assembly. Experience the efficiency of our cutting operations, ensuring every component is perfectly prepared for high-quality production. Contact us today to learn more about our advanced cutting capabilities.

Bending:

In the bending phase, advanced machinery precisely shapes the cut materials into the required curves and angles specified in your design. Automated bending systems adjust force and speed for consistent results, while skilled technicians monitor the process to prevent deformation. This ensures the structural integrity and aesthetic quality of your Wall Mount Network Rack components. Our meticulous bending process is critical for achieving accurate dimensions and repeatable quality. Contact us now to discover how our bending expertise can optimize your custom rack production.

Stamping:

During the stamping stage, high-speed equipment transforms raw metal into accurately stamped components. Custom dies and controlled presses ensure each detail is rendered with precision, creating clean edges and robust features. Automated monitoring systems maintain consistent pressure and timing throughout the process. This stamping operation is essential for producing reliable parts that meet design specifications. Experience superior precision with our stamping capabilities, which lay the foundation for a durable Wall Mount Network Rack. Reach out today to explore our stamping process further.

Welding:

Our welding phase employs automated systems and expert oversight to join components with robust, seamless welds. Controlled heat and pressure are applied to ensure strong bonds, while real-time monitoring and inspections verify weld quality. This process reinforces the structural integrity of your Wall Mount Network Rack, ensuring durability and long-lasting performance. Our advanced welding techniques guarantee consistent results, even under demanding conditions. Contact us today to learn how our welding operations contribute to the strength of your custom network rack.

Surface Treatment:

In the surface treatment stage, advanced finishing techniques are applied to enhance the durability and visual appeal of your Wall Mount Network Rack. Processes such as cleaning, polishing, and coating are executed under controlled conditions to protect against corrosion and wear. Automated systems ensure uniform application and optimal adhesion of protective layers. This step not only elevates aesthetics but also extends the product's lifespan. Discover how our surface treatment process transforms raw components into a premium finished product. Contact us now to discuss your specific finish requirements.

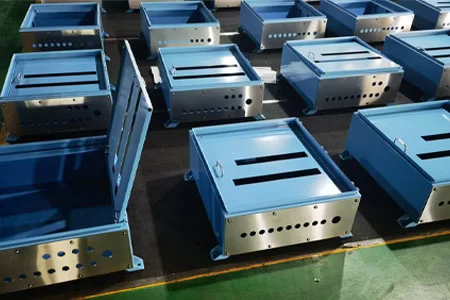

Assembly:

During assembly, all pre-processed components are meticulously integrated into a complete Wall Mount Network Rack. Automated assembly lines and skilled technicians work together to ensure precise alignment and secure fastening. Detailed quality checks are performed at every stage to confirm that the final product meets your custom specifications. This coordinated process results in a robust, ready-to-install rack that is both functional and aesthetically pleasing. Experience the precision of our assembly operations by contacting us today for a custom solution.

Packaging & Delivery:

After assembly, our packaging team prepares each Wall Mount Network Rack for safe transit. Using automated wrapping systems and careful manual inspections, we secure each unit with custom packaging solutions designed to protect against moisture, dust, and mechanical damage. Every package is labeled and sealed to maintain product integrity during shipping. Our efficient packaging process ensures that your rack arrives in pristine condition, ready for installation. Contact us now to learn more about our secure packaging methods.

After-sales Service:

Our aftersales service is dedicated to ensuring your complete satisfaction with our Wall Mount Network Racks. We offer hassle-free return, exchange, and replenishment services to address any issues upon delivery. Should you require additional stock or need to replace a unit, our responsive team is here to support you. Please note that our aftersales support does not cover repair or system assembly services. Rely on our commitment to service excellence—contact us today for prompt assistance with any post-delivery concerns.