Select the appropriate assembly process according to requirements such as drawings and assembly accuracy, arrange a more reasonable assembly process, and develop a complete solution. Our experienced assembly lines can complete your order with higher quali

Top Sheet Metal Assembly Factory Supplies

Better Sheet Metal Assembly Service

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

Start Sheet Metal Assembly at HULK METAL

We have advanced assembly lines, experienced workers, and strict assembly process management. Below, we will briefly describe how to complete high-quality orders quickly. Kindly contact us if you have an order and need OEM. Our sales manager will take you to visit the factory on-site or online..

-

Sheet Metal Assembly Machinery:

We have advanced welding, riveting, and thread-fastening equipment. We have established a complete assembly line to complete the assembly of each sheet metal part faster. Assembly is only an important part of our sheet metal fabrication. We also have advanced sheet metal cutting, stamping, and other equipment, quality testing equipment. Your order can be completed in one place with us, which can save more costs.

-

Experience:

We have provided excellent sheet metal assembly services to more than 20 industries, such as construction hardware, trailer manufacturing, fitness equipment manufacturing, automotive exterior sheet metal, etc. After more than 20 years of development, we are familiar with the performance of each material that can develop solutions, including sheet metal cutting, blanking, forming, surface treatment, assembly, and packaging according to the drawings. Contact us to get a better quote for you.

-

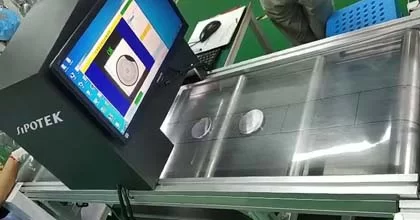

Quality:

The quality control center focuses on providing higher-quality products and quality inspection services. We have advanced testing equipment such as CMM, hardness tester, metallographic microscope, spectrometer, salt spray tester, etc. Before ordering production, we will develop a complete testing process to complete testing of the chemical properties and physical properties of the raw materials, semi-finished products, and finished products.

-

Services:

You can enjoy high-quality services through our complete supply chain. Our sales team will have an in-depth understanding of your needs, and then our technical team will develop a complete solution and calculate the price. Our factory will complete the production and delivery of the order according to the solution. We will follow up on the entire order process and give you feedback at any time. At HULK Metal, you save more time, effort, and money.

Sheet Metal Assembly Services Capacities

Complete sheet metal fabrication services we can offer. The following is a summary of our service capabilities, which cannot be introduced in detail due to space constraints. Kindly contact us if you want to fully understand before placing an order. We will take you to visit the factory, develop a more suitable and free solution, and quote you.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

SHEET METAL THICKNESS: | <=80mm |

PROCESS: | Sheet Metal Cutting, Stamping, Machining, Surface Treatment, Assembly. |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / According to Drawings & Materials |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Sheet Metal Assembly Service

We've sorted out how to provide quality sheet metal assembly services to our customers. When we choose a factory, we can also fully understand their production process to determine their professional capabilities. You can use our introduction as a comparison.

-

01

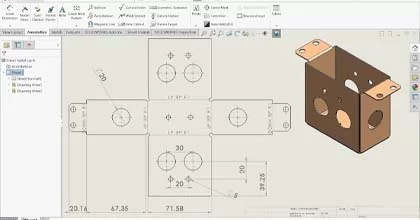

Get Drawings And Requirements

You need to send at least one 2D drawing and tell us some information you know, such as quantity, acceptable delivery methods, and some requirements not mentioned in the drawings, such as surface treatment method, packaging method, etc. Of course, our sales team will provide you with more suggestions during communication.

-

02

Custom Solutions

We will use your needs obtained through in-depth communication to improve all aspects of the solution. Your order will be completed strictly according to the solution. Any problems that arise will have effective and appropriate solutions.

-

03

Welding Samples Sending & Testing

After the solution is determined, we will complete the cutting, stamping, and other processes of sheet metal parts according to the process and complete quality inspection. We will send samples to you to compare the test data. After passing the inspection, we will arrange the details of the production and start manufacturing.

-

04

Order Scheduling

Based on the delivery date, order size, and other information, we will purchase raw materials in advance, arrange the production site, and replace molds so that we can complete the order more efficiently and with guaranteed quality and quantity.

-

05

Raw Materials Purchasing & Testing

The purchased raw materials need to undergo strict physical and chemical property testing first. Only raw materials that pass the inspection will be used for the production of orders. We will issue a product inspection report for each batch of products.

-

06

Raw Materials Cutting

We will use laser cutting to complete the pre-processing of raw materials to facilitate the stamping and forming process. In most cases, we use laser cutting because it can save more material and labor costs.

-

07

Sheet Metal Stamping

According to the structural characteristics of sheet metal parts, we need to use punching, bending, spinning, and other processes to complete the further processing of the cut raw materials.

-

08

Sheet Metal Welding

The stamped sheet metal parts are pre-assembled through the welding process. Surface treatment of the whole after welding can make the surface coating continuous and more uniform. Performance in all aspects will be even better.

-

09

Surface Treatment

Surface treatment needs to be selected according to the material of the sheet metal part and the specific usage scenario. The surface treatment services we can provide include galvanizing, electrophoresis, passivation, anodizing, polishing, wire drawing, etc. You can contact us to learn more.

-

010

Assembly

The surface-treated sheet metal parts need to be assembled to complete the final step. We have fully automatic screw machines, efficient riveting machines, and experienced operators to complete product assembly faster.

-

011

Warehousing & Delivery

We have a strictly managed warehousing center that can provide free temporary storage services for goods. Our logistics team can complete loading, transportation, port entry, and more faster. Realize seamless connection from factory to port, station, and air freight station. The professional freight consulting team can help you find a more suitable freight company to complete the final handover of goods.

-

012

After Service

We will be responsible for the quality of the goods you receive. We have a complete team to provide one-to-one service to develop solutions that satisfy you based on the problem.

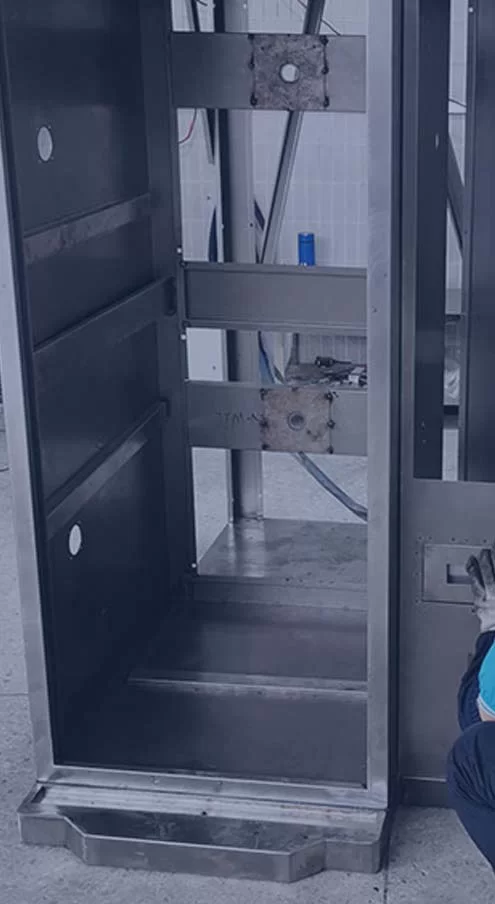

Parts Our Metal Assembly Service Produced

Here, you can see the sheet metal parts we have produced, such as automobile exterior sheet metal decorative parts, fitness equipment accessories, trailer parts, construction hardware, etc. We already provide sheet metal fabrication services to more than 20 industries. You can trust us with your order.

-

Trailer Tire Carrier Factory In China

Trailer Tire Carrier Factory In ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Support Legs Factory in China

Trailer Support Legs Factory in ChinaWe have a complete trailer support legs supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide.

READ MORE

-

Boat Trailer Roller Brackets OEM Factory

Boat Trailer Roller Brackets OEM FactoryBy integrating a comprehensive supply chain, we are committed to providing high-quality OEM services for boat trailer roller brackets to each customer.We sincerely invite you to contact us for solutions and quotations.

READ MORE

-

Boat Trailer Bunk Brackets Factory in China

Boat Trailer Bunk Brackets Factory in ChinaWe can use this component to construct a "V" structure on the trailer to secure the boat. It consists of three primary parts: the trailer connection, the support rod, and the support head.

READ MORE

-

Pickup Truck Bed Accessories OEM Factory

Pickup Truck Bed Accessories OEM FactoryWe have a complete pickup truck bed accessories supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide. We provide a complete QA Service.

READ MORE

More Results

Sheet Metal Assembly Serice Types We Can Supply

Here, we mainly introduce the two assembly methods - riveting and threaded fastening because both of these are non-welding assembly processes.

Sheet Metal Riveting

Sheet Metal Fastening

-

Sheet Metal Riveting

Sheet metal riveting refers to reserving riveting holes on two sheet metal parts that need to be assembled. During assembly, place solid rivets into the riveting interface and press them under the action of the machine to complete the riveting. In addition to the previously described riveting methods, current riveting methods include core rivets, flat head rivets, core blind rivets, etc. Solid rivets are the strongest type available. When assembling sheet metal, it is necessary to select appropriate rivets and reserve riveting holes of a specific size based on the strength requirements of the sheet metal parts. If you want to disassemble the riveted sheet metal parts, you can only destroy the rivets.

-

Sheet Metal Fastening

There are two types of threaded fastening links. One is to reserve threads on the sheet metal parts and use screws to directly fasten them. The other is to only reserve assembly holes and use threads and nuts for assembly. There are pros and cons to both approaches. The holes will be marked on the drawing to see if they have threads. There are two ways to process threaded holes: one is to use a tapping machine, and the other is to use turning. The first one is more advantageous. The biggest benefit of this assembly method is that it can be disassembled and installed at will.

View Our Assembly Factory

You can contact us to visit our sheet metal manufacturing factory on-site or online. We show here some production moments for you to understand briefly.

Sheet Metal Assembly Introduction

We've put together some information on sheet metal assembly. This can help you better understand what process your foundry uses to complete your order. You can learn and communicate with them at the same time.

-

Assembly

Sheet metal assembly services refer to the process in which sheet metal manufacturers equipped with assembly lines use riveting, welding, thread fastening, adhesive bonding, and crimping seams to complete the assembly of sheet metal parts. We need to choose the appropriate link method based on the performance requirements of the sheet metal parts in the usage scenario and the ease of transportation of the finished product.

-

Welding, Riveting, Screw Fasteners Link Comparison

Welding, riveting, and screw fastener links can all be used as a means of assembly in the metal fabrication process. Welding and riveting is a permanent process. After welding is completed, it can only be cut and separated. If not handled properly, the structure of the sheet metal parts will be damaged. It is more suitable for structures that will not easily change the shape. Linked locations can be unlinked and linked again using special tools. Riveted sheet metal parts have excellent shear resistance but weak tensile properties. Threaded fasteners are flexible links with relatively balanced shear and tension forces and are suitable for most environments.

From a convenience perspective, only threaded connections can be disassembled and reused at any time, while riveting and welding are one-time connections, and fasteners cannot be reused after installation.

From a complete point of view, threaded connections are the best, riveting is second, and welding is last.

From the perspective of quality control, threaded connections are more convenient and suitable for quality inspection and inspection at any time, followed by welding and riveting.

In terms of cost of use, the opposite is true. The cost of welding is relatively low, the cost of riveting is slightly higher, and the cost of threaded connection is the highest among the three connection methods.

In terms of lightweight construction, riveting is the lightest, followed by welding, and threaded connections are the highest.

Therefore, among these three methods, there is no way to compare which one is better. We can only say which one is more suitable for the installation environment.

Choose HULK Metal As Your OEM Factory

HULK Metal has a complete sheet metal manufacturing supply chain. In addition to assembly, we can also provide cutting, stamping, surface treatment, packaging, warehousing, transportation, freight consulting, and other services. Our OEM service can control order costs from all aspects. You can make higher quality products for less money at HULK Metal.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Article of Sheet Metal Assembly

Here, we have compiled some articles about sheet metal assembly to supplement some content that cannot be described in detail due to space. I hope they can help you understand welding more fully and find the foundry that suits you.