HULK Metal's factory has passed ISO 9001 and ISO 16949 double certification, with rich experience in precision stamping parts production, and is one of the top suppliers in China. The experienced technical team can develop a perfect solution according

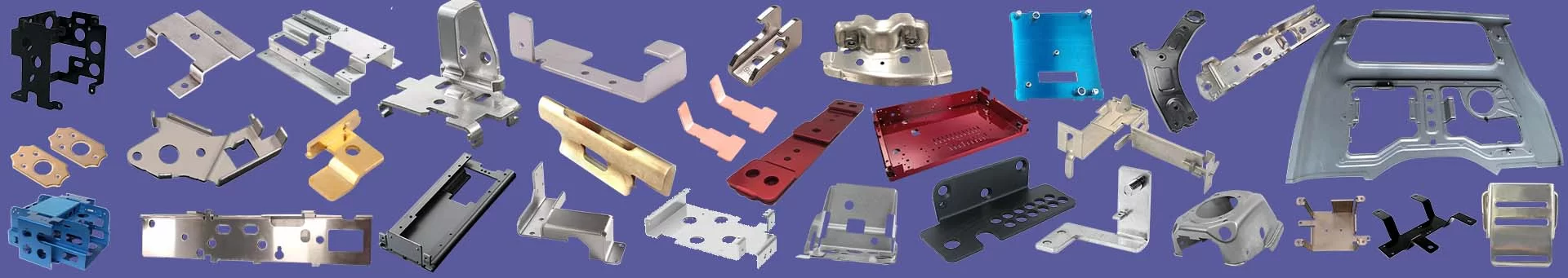

HULK Metal Is An Excellent Precision Stamping Parts Manufacturer in China

Provide Better Precision Stamping Parts OEM Services

Industries

-

- Stone Fixing Brackets Factory In China

- Custom Sheet Metal Brackets

- Wood Framing Connectors

- Steel Beam Clamps

- Precast Concrete Accessories

- Custom Sheet Metal Parts For Construction

- Post to Beam Connector

- Metal Beams Brackets

- Metal Base Plate

- Concrete Embeds Steel Embed Plates

- Angle Iron Connectors Construction Hardware

-

- Roof Rack Connectors Factory In China

- Universal Roof Rack Crossbars Factory in China

- Roof Bike Carriers For Cars Factory in China

- Pickup Truck Bed Accessories OEM Factory

- Pickup Truck Roll Bars OEM Factory

- Kayak Roof Rack OEM Service

- Cargo Baskets

- Car Bike Racks

- Heavy Duty Roof Racks

- Metal Roof Racks

-

- Trailer Tow Hitch Drop Plate Factory in China

- Winch Post for Boat Trailer Factory in China

- Trailer Tire Carrier Factory In China

- Trailer Support Legs Factory in China

- Trailer Stake Pocket Manufacturer In China

- Trailer Hitch Mount Factory in China

- Trailer Coupler Factory In China

- Boat Trailer Roller Brackets OEM Factory

- Boat Trailer Bunk Brackets Factory in China

- Boat Trailer Brackets Manufacturer In China

-

- Custom Wall Mount Network Rack

- Heavy Duty Network Server Cable Management

- Custom OEM Server Rack Blank Panels

- Custom Network Server Tray

- Wall Mount Network Racks

- Network Server Rack Tray Brackets

- 1U 2U 3U 4U Server Rack Blank Panels

- 18 to 47U Network Server Cabinets

- Network Server Rack Cable Management

- 18 to 47U Network Server Rack

-

- Laser Cutting Metal Parts Factory

- OEM Server Switch Rack Enclosure Cabinet

- Custom Metal Brackets Factory In China

- Carbon Steel Stamping Parts Factory in China

- Sheet Metal Spinning Parts Factory In China

- Stainless Steel Stamping Parts Factory In China

- Aluminum Stamping Parts Factory In China

- Sheet Metal Parts Manufacturer In China

- Precision Metal Stamping Parts Manufacturer

- OEM Auto Metal Stamping Parts Factory

- Stamped Steel Parts Factory

- Metal Stamping Parts Factory

- China OEM Metal Stamping Parts

-

Features

-

Capacities

-

Description

-

Factories Visit

-

Benefits

-

Articles

-

Review

-

Top