We have advanced CNC laser, plasma, and flame cutting machines. We can provide 0.1~45mm metal plate cutting services. The accuracy can reach ±0.05µm. Kindly contact us and send us drawings or samples. We will give you a more cost-effective solution.

Top Sheet Metal Factory

Sheet Metal Cutting Center

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

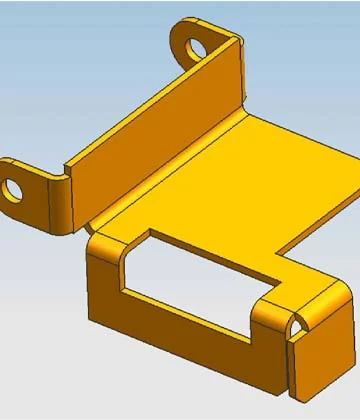

When your product needs to be cut or used as a pre-processing step, you need to choose the appropriate cutting method. Different materials and thicknesses, as well as the edge performance requirements of the accessories after cutting, all need to be considered when choosing the cutting method. Our laser cutting can complete most metal plate cutting work below 30mm. The minimum slit can reach 0.02mm (0.1mm thick metal plate). We will develop a complete solution based on your drawings and samples and achieve efficient, high-precision cutting through programming. Complete your order quickly.

SHEET METAL CUTTING PRODUCTION LINE

Below is shown a demonstration of our cutting center programming, cutting, and sheet metal cutting parts. You can contact us if you would like to learn more about our production capabilities. Our sales manager will take you to visit the factory online or on-site.

-

01Cutting Slit Show

The cut surface is smoother than other cutting methods.

-

02Advanced Fully Automatic Laser Cutter

Realize fully automatic production of sheet metal cutting parts through programming.

-

03Cutting

The process of laser cutting sheet metal, it's so beautiful.

-

04Metal Plate Cutaway Show

The thinnest slits of laser cutting can reach 0.02mm and will become larger and larger as the thickness of the plate becomes wider.

-

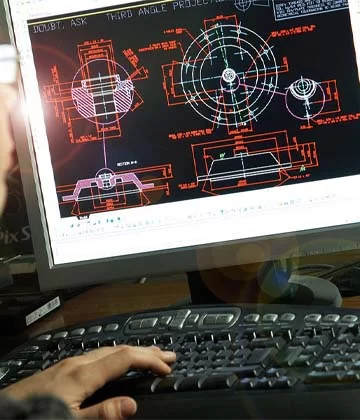

05Programming

Our engineers use CAD to complete cutting programming according to drawings to achieve more efficient cutting.

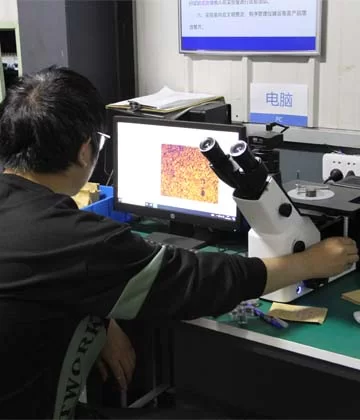

QUALITY CONTROL CENTER

Our quality control center can complete the testing of sheet metal cutting parts' tolerances, shapes, cut metal properties, chemical properties, and other mechanical properties according to your requirements.

-

Hardness Tester

Has Brinell and Rockwell hardness testers. Meet various requirements for hardness measurement.

-

CMM

It can more accurately measure the size of sheet metal cutting parts.

-

Impact Tester

It is used to measure the resistance of sheet metal cutting parts to high-speed loads under different environmental conditions.

-

Salt Spray Test Machine

Place the sheet metal parts in a simulated environment to test their oxidation resistance, corrosion resistance, etc.

-

Tensile Testing Machine

Complete various tests, such as tension, compression, bending, shearing, peeling, tearing, and two-point extension of sheet metal cutting parts.

-

Spectrograph

Detect the types and contents of elements in sheet metal parts.

HOW DO WE FULFILL ORDERS FOR SHEET METAL CUTTING PARTS

You can see the order completion process here. Due to limited space, we can only briefly describe it. Kindly contact us to experience our services, visit our factory, and get the latest quotation.

-

PART 01Custom A Suitable Solution

PART 01Custom A Suitable SolutionOur service team will connect with you and develop a solution more suitable for you, including the cutting process, raw material procurement, production, quality inspection, packaging, and delivery, after an in-depth understanding of your needs. With this solution, you can save more costs.

-

PART 02Formulate a Quality Inspection Plan

PART 02Formulate a Quality Inspection PlanThe quality inspection center will formulate a comprehensive testing plan based on the performance requirements of sheet metal cutting parts and conduct various performance tests of raw materials, semi-finished products, and finished products. Each order is accompanied by inspection reports of materials and finished products.

-

PART 03Programming

PART 03ProgrammingThe technical team will use CAD and other cutting programming software to design the program for the CNC laser cutting machine based on the drawings or samples. A high-quality program can cut sheet metal parts more efficiently and maintain higher repeatability.

-

PART 04Make Samples

PART 04Make SamplesWe will trial-produce multiple samples according to the process of the solution, leave a few for quality inspection ourselves, and then send them to you for testing. In this way, detection criteria are the same at both ends.

-

PART 05Raw Material Purchasing

PART 05Raw Material PurchasingWe have close cooperation with raw material suppliers and can obtain lower supply prices than those on the market. When purchasing in larger quantities, the purchase price will be more advantageous. The purchased raw materials will be put into production after passing strict physical and chemical property testing.

-

PART 06Cutting

PART 06CuttingLaser cutting is used to cut sheet metal parts below 30mm. Digital control ensures cutting efficiency and repeatability. Finer cutting seams and smoother cutting surfaces allow us to save more processing costs and material costs. Cut parts can be stamped, welded, or packaged after machining and surface treatment.

-

PART 07Machining

PART 07MachiningCarry out drilling, edge trimming, tapping, and processing of external edges. The processed sheet metal cutting parts can be subjected to subsequent surface treatment and assembly work.

-

PART 08Surface Treatment

PART 08Surface TreatmentWe will complete galvanizing, powder coating, electrophoresis, anodizing, and other treatments according to your requirements. We have close cooperation with surface treatment factories, and larger orders can obtain more price discounts.

-

PART 09Packaging

PART 09PackagingWe provide customized services such as material and appearance. For corrugated boxes, kraft boxes, wooden boxes, and other packaging methods, We can supply isolation packaging for sheet metal stamping parts that need to protect their appearance.

-

PART 10Warehousing

PART 10WarehousingThe packaged goods will be stored in our strictly managed warehouse, waiting for collective or batch shipment according to your needs.

-

PART 11Delivery

PART 11DeliveryWe have our own logistics team that can achieve rapid transfer of goods from the factory to the designated port. The freight consultation center can help you find a more suitable one from many freight companies.

-

PART 12After Service

PART 12After ServiceAfter-sales service will solve your goods quality problems, and we provide return, exchange, and replenishment services. You can contact our sales manager after discovering the problem, and we will propose a solution that satisfies you.

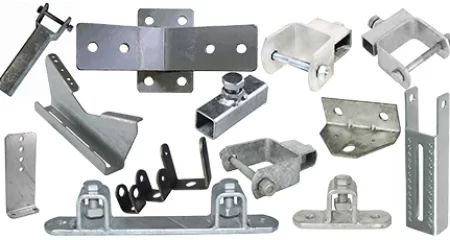

SHEET METAL CUTTING PARTS HULK METAL PRODUCED

Shown here are some of the sheet metal cut parts we have produced since 2000. We have provided sheet metal cutting services to more than 20 industries. You can contact us for more suitable solutions and quotations.

-

Trailer Tow Hitch Drop Plate Factory in China

Trailer Tow Hitch Drop Plate Factory in ChinaOur OEM Trailer Tow Hitch Drop Plate is generally made of high-performance carbon steel, which can withstand the weight and stress during towing. The finished product needs to pass strict random inspections to ensure the qualified rate.

READ MORE

-

Trailer Support Legs Factory in China

Trailer Support Legs Factory in ChinaWe have a complete trailer support legs supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide.

READ MORE

-

Trailer Hitch Mount Factory in China

Trailer Hitch Mount Factory in ChinaWe have a sheet metal manufacturing facility certified by ISO 9001 and ISO 16949, capable of providing high-quality OEM services for your trailer hitch mounts. Our integrated supply chain ensures the efficient completion of every order.

READ MORE

-

Boat Trailer Roller Brackets OEM Factory

Boat Trailer Roller Brackets OEM FactoryBy integrating a comprehensive supply chain, we are committed to providing high-quality OEM services for boat trailer roller brackets to each customer.We sincerely invite you to contact us for solutions and quotations.

READ MORE

-

Boat Trailer Brackets Manufacturer In China

Boat Trailer Brackets Manufacturer In ChinaWe can use this component to construct a "V" structure on the trailer to secure the boat. It consists of three primary parts: the trailer connection, the support rod, and the support head.

READ MORE

-

Universal Roof Rack Crossbars Factory in China

Universal Roof Rack Crossbars Factory in ChinaHULK Metal is a metal fabrication factory with ISO 9001 and ISO 16949 dual certifications. We can provide you with a full range of OEM services such as metal cutting, stamping, welding, surface treatment, etc.

READ MORE

-

Pickup Truck Bed Accessories OEM Factory

Pickup Truck Bed Accessories OEM FactoryWe have a complete pickup truck bed accessories supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide. We provide a complete QA Service.

READ MORE

-

Kayak Roof Rack OEM Service

Kayak Roof Rack OEM ServiceThe goal of our OEM Kayak Roof Rack is to be more durable and safer, and on this basis, control its cost. We hope to gain more customers through perfect services and high-quality products.

READ MORE

-

Heavy Duty Roof Racks

Heavy Duty Roof RacksIts load capacity is stronger than ordinary roof racks. Therefore, its material requirements are more stringent. Even if it is made of the same material, its production thickness will be thicker.

READ MORE

-

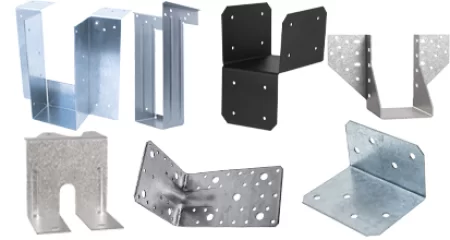

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

Custom Sheet Metal Parts For Construction

Custom Sheet Metal Parts For ConstructionWe provide more comprehensive services by vertically integrating the raw material, packaging, and freight, and horizontally integrating various sheet metal factories to produce better Sheet Metal Parts.

READ MORE

-

Metal Beams Brackets

Metal Beams BracketsHULK Metal can provide high-quality metal beams brackets because our sheet metal factory has advanced cutting machines, stamping, and welding equipment, experienced workers, and QC center.

READ MORE

More Results

YOU WILL GET AT HULK METAL

When you choose HULK Metal as a sheet metal cutting factory, you can get higher quality sheet metal cutting parts at lower prices from us, have an easier purchasing experience, and save more time and energy. The detailed reasons are explained to you below.

-

Get Higher Quality Parts

Our factory strictly implements ISO 9001 quality management, and every quality problem can be quickly found and solved. Advanced CNC cutting machine tools can achieve higher repeatability without any errors when without program errors and machine failures. The advanced quality control center and strict testing procedures all ensure quality. We also provide quality guaranteed after-sales service. So you can place your order with us with complete confidence.

-

Get Goods Faster

We will shorten the order production time by more rationally arranging the procurement time of raw materials and the production process sequence. Our outsourcing factories are very close to us, which reduces time wastage caused by long-distance transportation. The factory is located in a port city and has natural geographical advantages. We have warehousing, physical, and freight company consulting teams to achieve the perfect connection of goods from the factory to your hands.

-

Spend Less Money

The technical team will consider the tolerances, complexity, surface accuracy, surface treatment methods, and other requirements of sheet metal cutting parts to control the order cost by selecting a more appropriate production process and sequence. We can minimize costs without affecting product quality. We can also use the complete supply chain to save costs from raw materials, packaging, warehousing logistics, and cross-border freight when your purchase quantity is larger.

-

Spend Less Time & Energy

Perfect services can help you save more energy and time. We have established a full-service team, including sales, technology, procurement, production, quality inspection, logistics, international freight company consulting, and after-sales service personnel to serve you. Any problems you encounter during consultation, after placing an order, during the production process, or after the order is delivered will be solved promptly and effectively by them.

ARTICLES OF SHEET METAL CUTTING

Here, we compile articles about sheet metal cutting. They introduce you to sheet metal cutting equipment, materials, and factory selection in more detail. You can contact us for a more suitable solution and quotation when you need to find a more suitable OEM factory for sheet metal cutting parts.