We will choose the more suitable one from welding, brazing, and pressure welding processes to complete your sheet metal order based on material, accuracy, and other requirements. Kindly contact us for solutions and more competitive quotes.

Excellent Sheet Metal Welding Factory Supplier

Better Sheet Metal Welding Service

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

Start Sheet Metal Welding at HULK METAL

When you become familiar with the materials and sheet metal structures that are more suitable for each welding method, as well as the mechanical properties of the welds and other techniques, you can choose a more suitable welding process to complete your order based on the various requirements of the sheet metal parts.

-

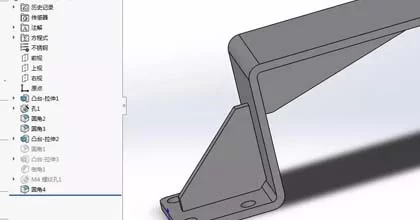

Sheet Metal Welding Machinery:

Our variety of advanced welding equipment can complete orders using fusion welding, pressure welding and brazing processes according to the performance requirements of the workpiece on the weld. The arc welding machine can complete the welding of all metal materials and the welds have high-quality mechanical properties. The spot welding machine is used for welding stamping parts less than 4mm and without sealing requirements. Brazing is used to weld more precise, complex, and thin parts. Sheet metal gold structure.

-

Experience:

The experienced welding team has an average of more than 15 years of experience and is certified. They can skillfully operate automatic welding machines to complete the welding of large-volume orders and can also manually weld small-volume orders. Our welding team's one-time welding pass rate is close to 100%. This greatly shortens the order lead time and reduces order costs.

-

Quality:

Our quality control center has a CMM, spectrometer, hardness tester, impact testing machine, metallographic microscope, tensile testing machine, salt spray testing machine, etc., and has strict quality inspection operation rules. We will develop a complete quality inspection process based on customer requirements. It has been ensured that all indicators of the product can meet customer requirements. Strict material and product testing reports will be issued for every batch of goods.

-

Services:

High-quality service can help you save more energy and time. We have established a service team including sales, technology, procurement, production, packaging, quality inspection, warehousing, logistics, freight consulting, after-sales and other members. We will promptly and effectively solve your various purchasing problems, saving you a lot of time.

Shett Metal Welding Services Capacities

We have summarized our service capabilities in a table. This will give you an idea of our range of welding services. You can send us the drawings. We will develop a complete production solution and calculate a more competitive quotation.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

SHEET METAL THICKNESS: | <=80mm |

PROCESS: | Fusion Welding / Pressure Welding / Brazing |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / According to Drawings & Materials |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Sheet Metal Welding Service

Below, we will briefly introduce how your order goes from drawings to real goods. You can contact us. We will take you to visit the factory online or on-site. You can also send us the drawings. Our technical team will help you calculate a more competitive quote.

-

01

Get Drawings And Requirements

You need to send at least one 2D drawing and tell us some information you know, such as quantity, acceptable delivery methods, and some requirements not mentioned in the drawings, such as surface treatment method, packaging method, etc. Of course, our sales team will provide you with more suggestions when communicating with you.

-

02

Custom Solutions

We will use your needs obtained through in-depth communication to improve all aspects of the solution. Your order will be completed strictly according to the solution. Any problems that arise will have effective and appropriate solutions.

-

03

Welding Samples Sending & Testing

We will weld multiple samples according to the solution process for weld metallography, defects, mechanical properties, etc. (if required). Samples will also be sent to you for testing. We will start arranging the order after the sample passes the inspection.

-

04

Order Scheduling

We will reasonably arrange the order of raw material procurement, production, machining, surface treatment, packaging, and other processes based on the order size, factory production saturation, etc. Your order can be produced faster.

-

05

Raw Materials Purchasing

We will conduct strict random inspections to test their chemical composition and physical properties before raw materials enter the factory.

-

06

Parts Manufacturing

Use cutting, punching, forming, and other sheet metal manufacturing processes to complete the accessories. During the manufacturing process of accessories, it is necessary to detect their factory, shape, and mechanical properties.

-

07

Welding

Select the appropriate welding process according to the material, the thickness of accessories, etc., to improve the mechanical properties of the weld and the order qualification rate and shorten the lead time of the order.

-

08

Packaging

For stainless steel and aluminum sheet metal parts with high surface precision, such as brushed, polished, and anodized, they can be coated (higher price) or packed with bubble pad isolation. We also support packaging box material and appearance customization.

-

09

Warehousing & Delivery

We have a strictly managed warehousing center that can provide free temporary storage services for goods. Our logistics team can complete loading, transportation, port entry, and more faster. Realize seamless connection from factory to port, station, and air freight station. The professional freight consulting team can help you find a more suitable freight company to complete the final handover of goods.

-

010

After Service

We will be responsible for the quality of the goods you receive. We have a complete team to provide one-to-one service to develop solutions that satisfy you based on the problem.

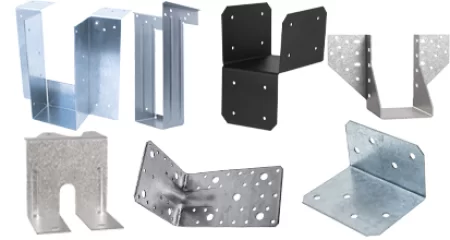

Parts Our Metal Welding Service Produced

We have provided sheet metal welding services to more than 20 industries, such as automobile exterior decoration, trailers, fitness equipment, construction hardware, etc. These are schematics of the products we have produced. You can send us the drawings. Our sales manager will communicate the details with you and develop a more suitable solution.

-

Roof Rack Connectors Factory In China

Roof Rack Connectors Factory In ChinaWe focus on providing customers with high-quality metal fabrication services. To this end, we have integrated high-quality factory resources and established a complete supply chain.

READ MORE

-

Pickup Truck Bed Accessories OEM Factory

Pickup Truck Bed Accessories OEM FactoryWe have a complete pickup truck bed accessories supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide. We provide a complete QA Service.

READ MORE

-

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

Post to Beam Connector

Post to Beam ConnectorHULK Metal focuses on providing high-quality sheet metal manufacturing services to global sheet metal purchasers. So far, we have produced millions of items of more than a dozen types for customers.

READ MORE

-

Concrete Embeds Steel Embed Plates

Concrete Embeds Steel Embed PlatesHULK Metal is committed to producing higher-quality steel embed plates through high-quality sheet metal manufacturing services. Kindly contact us for a better quotation.

READ MORE

More Results

Sheet Metal Welding Serice Types HULK Metal Can Supply

Choosing the appropriate welding process can greatly improve production efficiency, shorten order delivery cycles, and reduce order costs. The welding processes we can provide include laser welding, spot welding, arc welding, etc.

Laser Welding

Arc Welding

Sheet Metal Spot Welding

-

Laser Welding

Laser welding can be used to weld materials with precise joints, less than 19mm, and relatively low reflectivity and thermal conductivity. At present, we use the laser to weld some stainless steel, steel, iron sheet metal parts, etc., to require high welding prices.

-

Arc Welding

The arc welding process can be used to weld all metal materials, such as aluminum, magnesium, copper, nickel and their alloys, stainless steel, carbon steel, low alloy structural steel, etc. We use the argon arc welding process. It is necessary to decide whether to use X-ray flaw detection for welds according to requirements (must be done for pressure vessels, etc.

-

Sheet Metal Spot Welding

We use spot welding process to complete the welding of sheet metal parts below 4mm. Using spot welding to complete the welding of orders can effectively reduce labor costs. We have advanced welding machines that can effectively ensure welding quality.

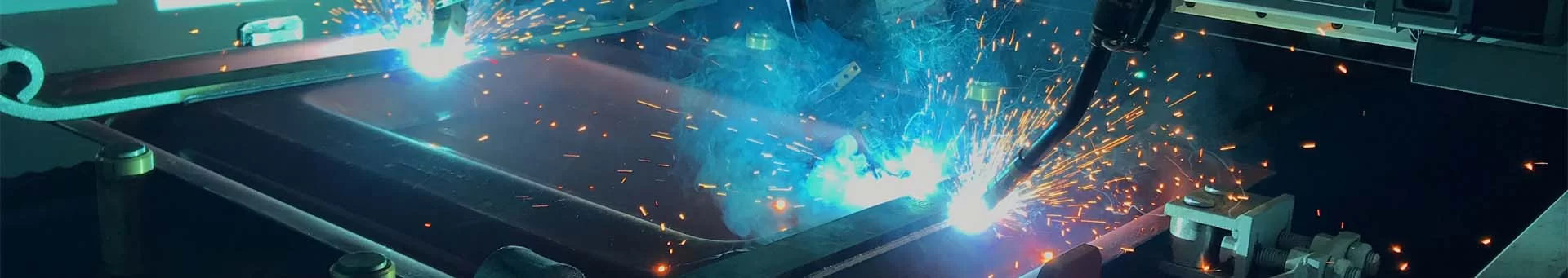

View HULK Metal Welding Factory

HULK Metal's welding workshop has a variety of welding equipment to meet the requirements of different materials and mechanical properties of welds. Kindly contact us if you would like a site visit. We will take you to visit our factory and explain it in detail.

-

Argon Arc Welding

The moment when the master uses argon arc welding to weld steel sheet metal parts.

-

QC Center

Quality inspectors test product performance.

-

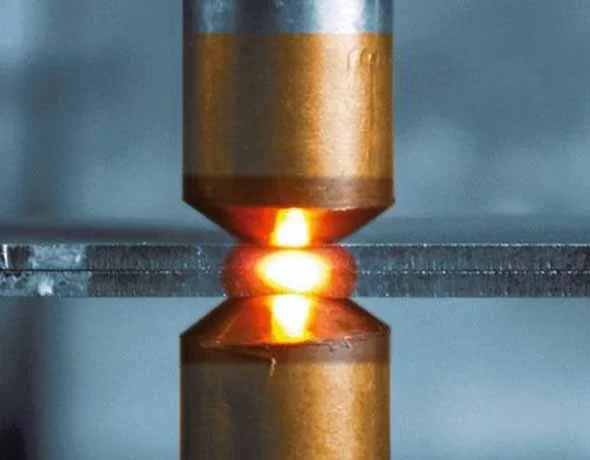

Spot Welding Moment

The moment a spot welder welds sheet metal parts.

-

Sheet Metal Welding Workshop

A variety of welding equipment can be used for welding sheet metal parts made of aluminum, steel, iron, and other materials.

Sheet Metal Welding Introduction

Here, We have compiled some concepts about welding so that you can fully understand the welding process, types, and applications. We also briefly talked about how you will benefit from choosing HULK Metal's OEM services.

-

Sheet Metal Welding

It is a metal fabrication process in which we use heating, high pressure, etc., to melt metal links and splice multiple block metal structures together. Welding is divided into three types according to the joining method: fusion welding, pressure welding, and brazing. And according to specific energy methods, such as chemical energy gas welding, explosion welding, flame brazing, electric arc welding, resistance spot welding, soft soldering, mechanical friction pressure welding, light energy laser welding, etc. The above welding methods are suitable for most metals. Choosing the appropriate process based on the metal type, sheet metal performance, and other requirements can improve the processing efficiency of the order and shorten the lead time.

-

Welding, Riveting, Screw Fasteners Link Comparison

Welding, riveting, and screw fastener links can all be used as a means of assembly in the metal fabrication process. Welding is a permanent process. After welding is completed, it can only be cut and separated. If not handled properly, the structure of the sheet metal parts will be damaged. It is more suitable for structures that will not easily change the shape. Riveting can be regarded as a semi-permanent connection, and the connecting position can be released and reconnected using special tools. Sheet metal parts that are easy to transport or that are inconvenient to assemble on-site can be riveted. Threaded fasteners are flexible links that can be easily linked and disassembled. Sheet metal parts with complex shapes that are inconvenient to transport can be linked with threaded fasteners.

Choose HULK Metal As Your OEM Factory

HULK Metal has a complete sheet metal fabrication supply chain. In addition to welding, we can also provide cutting, stamping, surface treatment, overall assembly, packaging, warehousing, transportation, freight consulting, and other services. Our OEM service can control order costs from all aspects. You can make higher quality products for less money at HULK Metal.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Article of Sheet Metal Welding

Here, we have compiled some articles about sheet metal welding to supplement some content that cannot be described in detail due to space. I hope they can help you understand welding more fully and find the foundry that suits you.