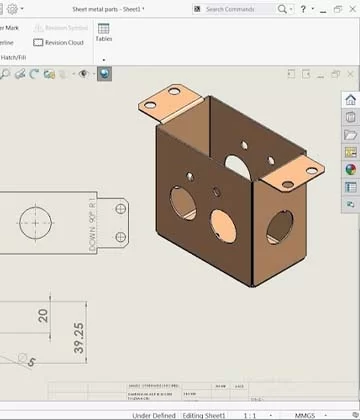

Our sheet metal stamping factory has more than 20 punch presses of 300 tons, 250 tons, 160 tons, 120 tons, and other tonnages, which can complete the punching and forming of sheet metal parts of most thicknesses and sizes. We can help you specify a more c

To Manufacture Better Sheet Metal Stamping Parts

HULK Metal Sheet Metal Stamping Facotry

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

In addition to providing production services such as blanking and forming, sheet metal stamping factories also provide auxiliary services such as sheet metal cutting, welding, machining, surface treatment, and assembly. High-quality factories have more advanced punching machines, testing equipment, cutting machines, welding machines, welding surface treatment centers, and experienced production teams. Sheet metal manufacturers with a complete supply chain can also provide technical support, packaging customization, warehousing logistics, and after-sales services. When choosing a suitable OEM factory, you can consider comprehensively the service content, product quality, overall price, and other factors. When we serve buyers with high demand, we can use the supply chain to save them more costs. Kindly contact us for complete solutions and quotes.

HULK METAL Sheet Metal Stamping Factory Equipment

In this section, you can see the various equipment in our stamping factory to better understand our production capabilities. You can contact us to take you to visit our factory on-site or via video call.

-

01220 Tons Punch Machine

We often use it to produce larger sheet metal stamping parts such as fitness equipment accessories, trailer accessories, and automotive exterior trim accessories.

-

0260 Tons Punch Machine

They can be used to produce thinner galvanized iron and galvanized steel plate connectors, etc.

-

03300 Tons Punch Machine

We can use it to complete the punching and forming of thicker sheet metal parts. The specific thickness needs to be calculated based on the material and side length.

-

04CNC Machining Center

Drilling, tapping, surface adjustment, hole repair, surface adjustment, and other processes all need to be completed by CNC machining centers. The accuracy can be controlled to ±0.5µm.

-

05Surface Treatment Line

Surface treatment requires acid or alkali washing and other processes to remove surface impurities of sheet metal parts before powder spraying, anodizing, passivation, electrophoresis, etc.

Moments Of Sheet Metal Stamping

In this section, you can see how our experienced workers use advanced equipment to complete your order. You can contact us to take you to visit our factory on-site or via video call.

-

Quality Control Moment

Quality inspectors test various properties of sheet metal stamping parts.

-

Sheet Metal Bending

Use a bending die to bend specific sheet metal parts on a punch machine.

-

Sheet Metal Bulging

Workers use the bulging process to complete the production of specific sheet metal parts.

-

Sheet Metal Blanking

-

Sheet Metal Spinning

The spinning mold is used to spin the sheet metal part into a specific shape at a specific position under the pressure of the punching machine or to make a spinning part directly.

-

Sheet Metal Punching

A punch is used to create holes in specific locations on the sheet metal part.

Process Of We Produce Your Sheet Metal Stamping Parts

Developing more appropriate solutions based on drawings or samples of sheet metal stamping parts and strict management will make the production process more reasonable. Provide follow-up support with high-quality packaging, warehousing, logistics, and other services. I will introduce it to you in more detail below.

-

PART 01Understand Your Needs Deeply

PART 01Understand Your Needs DeeplyThe sales managers you will contact have extensive experience in sheet metal stamping and order management because they have served customers with annual purchases of tens of thousands of tons. They will deeply understand your needs and lead the team for one-on-one service.

-

PART 02Custom Solution Based on Drawings Or Samples

PART 02Custom Solution Based on Drawings Or SamplesTechnical staff will analyze drawings or samples and more detailed requirements to formulate a complete production solution. This will ensure that the order can be delivered within the agreed time, its quality will be higher, and the price will be relatively lower.

-

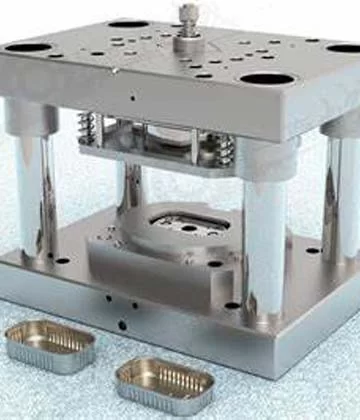

PART 03Select & Design the Stamping Molds

PART 03Select & Design the Stamping MoldsWe will complete the trial production of samples according to the process of the solution. A portion of the sample will be sent to you for testing. We do some of our own testing to ensure consistency in testing standards. After the sample test passes, we will start order production.

-

PART 04Making & Send Samples

PART 04Making & Send SamplesWe will complete the trial production of samples according to the process of the solution. A portion of the sample will be sent to you for testing. We do some of our own testing to ensure consistency in testing standards. After the sample test passes, we will start order production.

-

PART 05Order Scheduling & Raw Material Purchasing

PART 05Order Scheduling & Raw Material PurchasingWe will schedule production resources based on a comprehensive analysis of the current production order situation and your order situation. Ensure that your order is of high quality and quantity and completed within the agreed time. Raw materials will be prepared before production of the order begins.

-

PART 06Sheet Metal Stamping

PART 06Sheet Metal StampingThe aluminum, iron, carbon steel, or stainless steel plate is deformed or plastically deformed according to the shape of the mold under the pressure of the punch machine to the shape we want.

-

PART 07Machining

PART 07MachiningProcess threads, holes, and edges on stamped sheet metal parts. Our processing accuracy can reach 0.5µm.

-

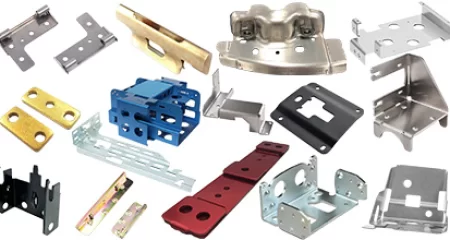

PART 08Surface Treatment

PART 08Surface TreatmentWe provide powder coating, anodizing (aluminum), electrophoresis, and other surface treatments.

-

PART 09Quality Control

PART 09Quality ControlQuality control will cover all aspects of the entire order. We will provide complete material, finished product, and surface treatment test reports as required.

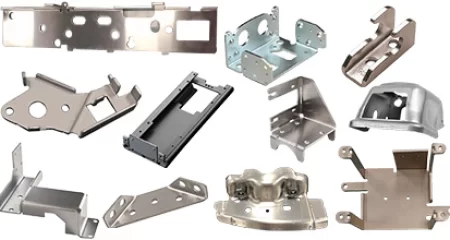

Sheet Metal Parts We Machined

To date, we have produced hundreds of products for more than 20 industries, such as automobile exterior decoration, trailer manufacturing, construction hardware, and fitness equipment manufacturing. We will develop a perfect solution based on your drawings. Kindly contact us to get the latest quote.

-

Stainless Steel Stamping Parts Factory In China

Stainless Steel Stamping Parts Factory In ChinaHULK Metal is one of the top OEM service providers in China with an ISO9001 certified stainless steel stamping parts factory. Contact us to get the latest discount prices.

READ MORE

-

Aluminum Stamping Parts Factory In China

Aluminum Stamping Parts Factory In ChinaHULK Metal is a well-known sheet metal parts manufacturer in China, which provides complete solutions to produce higher quality customized sheet metal parts at lower prices.

READ MORE

-

Precision Metal Stamping Parts Manufacturer

Precision Metal Stamping Parts ManufacturerHULK Metal's factory has passed ISO 9001 and ISO 16949 double certification, with rich experience in precision stamping parts production, and is one of the top suppliers in China.

READ MORE

-

OEM Auto Metal Stamping Parts Factory

OEM Auto Metal Stamping Parts FactoryOur factory is certified by ISO 9001 and ISO 16949. Our experienced technical team can develop a more complete solution according to the drawings and requirements.

READ MORE

-

Stamped Steel Parts Factory

Stamped Steel Parts FactoryStamped steel parts are made of carbon steel, alloy steel, and other plates into workpieces with specific shapes and functions using stamping processes such as blanking, bending, bulging, spinning, shrinking, flanging, etc.

READ MORE

-

China OEM Metal Stamping Parts

China OEM Metal Stamping PartsWe have abundant stamping factory resources and a complete supply chain to provide high-quality metal stamping parts OEM services. We have accumulated rich experience in OEM for hundreds of customers around the world and thousands of products.

READ MORE

More Results

Choose HULK Metal Stamping You Will Get

We have a complete supply chain, an experienced team, and advanced equipment. We will use our advantages to provide more thoughtful services, produce products that satisfy you, and deliver your orders faster, helping you save more costs in the process.

-

Get Higher Quality Sheet Metal Stamping Parts

Our factory strictly implements ISO 9001. A professional quality inspection team and advanced testing instruments ensure the provision of high-standard sheet metal parts. We will develop a complete testing plan according to your requirements and complete testing of raw materials, semi-finished and finished products. We will provide quality inspection reports on materials and finished products and are responsible for the quality of each product. We provide comprehensive quality assurance services.

-

Get Goods Faster

Experienced workers can be more proficient in using and maintaining the punch press. They ensure high repeatability during sheet metal production. Orders can be produced faster. Our warehousing and logistics center can realize the rapid transportation of goods in factories, warehouses, and ports to shorten the time of goods on the road. The Freight Consultation Center can help you find a more suitable international logistics company to deliver your goods faster.

-

Spend Less Money

When you purchase higher quantities of sheet metal parts, our supply chain will show its greatest advantage - helping you save more money. We work closely with raw material suppliers and other collaborating factories, which means we can obtain prices that others cannot. Larger orders can keep our supply chain running for a long time and save a lot of labor, time, and other costs.

-

Spend Less Time & Energy

The sales manager will lead a service team, including raw material procurement, production, quality inspection, freight, after-sales, and other personnel to provide you with one-to-one service. Any problems you have before ordering, during production, and after delivery can be solved promptly and properly. We will use pictures, videos, and video calls to let you know the real-time status of your order, even in the office.

Articles of Sheet Metal Stamping

We've put together content about sheet metal stamping for you to check out. You can see here the introduction, advantages and disadvantages, and applications of various sheet metal stamping processes.