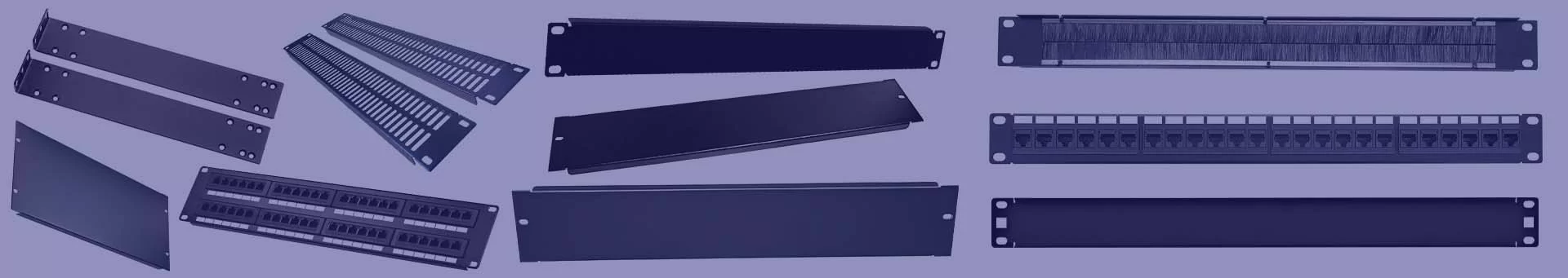

Processes of Complete Custom OEM Server Rack Blank Panels:

Our systematic manufacturing process transforms your drawings into premium Custom OEM Server Rack Blank Panels. Every step—from initial planning to final packaging and aftersales—is executed with precision and strict quality control. Ready to start your project? Contact us for a tailored solution that meets your timeline and budget.

Develop a Production Solution Based on the Drawings:

Based on your detailed drawings, our expert engineers develop a comprehensive production plan that outlines every critical step—from material selection to final quality checks. We analyze design parameters, dimensions, and performance requirements to ensure our approach aligns perfectly with your vision. This plan addresses potential challenges and incorporates innovative solutions to optimize manufacturing efficiency. Clear timelines, resource allocation, and risk management strategies are established from the outset, ensuring a seamless transition to production. By meticulously planning each phase, we lay the groundwork for precision manufacturing and timely delivery. Contact us today to discuss your custom requirements and let’s start planning your success.

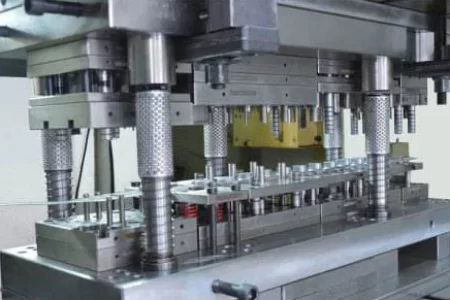

Mold Making:

Following the production plan, our specialized team crafts precision molds tailored to your design. Utilizing advanced CNC machinery and innovative techniques, we ensure each mold accurately reflects your specifications. Our rigorous process includes detailed inspections and iterative adjustments to guarantee perfect replication. The custom molds not only streamline production but also enhance repeatability and quality in every panel. Our commitment to excellence means that every mold is built to last and deliver consistent results. By investing in precision at this early stage, we secure the foundation for high-quality production. Reach out to us to see how our molding capabilities can bring your vision to life.

Sample Trial Production and Adjustment:

After mold creation, we produce initial samples for comprehensive testing and evaluation. Our experienced team rigorously examines each sample to ensure dimensional accuracy, finish quality, and performance under operational conditions. Feedback from this trial phase is invaluable; any discrepancies are addressed through careful adjustments and refinements to both the mold and process parameters. This iterative approach guarantees that the final product meets your unique requirements. Our commitment to quality ensures that every panel is optimized for durability and functionality before mass production begins. We invite you to collaborate with us during the sampling phase to perfect your custom design and achieve exceptional results.

Quality Control Plan Establishment:

With successful sample validation, our quality control team develops a comprehensive quality control plan that spans every stage of production. This plan establishes stringent inspection protocols and testing benchmarks for materials, dimensions, and surface finishes. Utilizing advanced measurement tools and real-time monitoring systems, we ensure that each component meets rigorous quality standards. The plan also outlines corrective action procedures to address any deviations promptly. Our proactive quality management approach minimizes defects and guarantees consistent product performance. We are committed to delivering flawless Custom OEM Server Rack Blank Panels that exceed your expectations. Contact us now to experience our uncompromising quality assurance in action.

Production Scheduling:

Production scheduling is the backbone of our manufacturing process, ensuring timely delivery and efficient resource allocation. Our scheduling team coordinates tasks meticulously, aligning production runs with client deadlines and material availability. Planning software and historical production data guide our schedule, minimizing downtime and optimizing workflow. By strategically sequencing each operation, we balance workload and maintain steady production rates. Regular reviews and adjustments ensure that our schedule remains flexible and responsive to unexpected changes. This organized approach not only enhances productivity but also builds trust with our clients. Efficient scheduling is key to delivering high-quality custom network server trays on time.

Raw Material Procurement:

Following scheduling, our procurement team sources high-quality raw materials that meet the strict specifications required for your custom panels. We partner with reliable suppliers to secure metals and components that offer superior durability and performance. Every material batch is thoroughly inspected to ensure compliance with our quality standards. This rigorous selection process not only guarantees the longevity of the final product but also maintains consistency across production runs. By focusing on quality from the very beginning, we lay a solid foundation for excellence in every panel we produce. Our dedicated procurement process ensures timely delivery of materials, keeping your project on schedule. Contact us to learn more about our material sourcing practices.

Laser Cutting:

In the cutting phase, advanced machinery precisely slices raw materials according to the exact dimensions outlined in your design. Automated systems ensure accuracy and consistency while minimizing waste. High-precision sensors and digital controls monitor the cutting process in real-time, allowing for immediate adjustments to maintain strict tolerances. Our cutting process is optimized for efficiency and quality, ensuring that every panel component is prepared flawlessly for subsequent manufacturing steps. This meticulous attention to detail sets the stage for high-quality production and seamless integration with later processes. Experience the precision and reliability of our cutting technology by reaching out to our team today for more information on our capabilities.

Bending:

The bending stage transforms cut components into the precise shapes required for your custom panels. Utilizing automated bending equipment, we adjust force and angle to achieve uniform curves and edges that adhere to your specifications. Real-time monitoring ensures consistency and prevents deformation during the process. Our skilled technicians oversee the operation, making sure every bend meets exact design requirements. This controlled bending process not only enhances the structural integrity of the panels but also contributes to their aesthetic appeal. The precision and repeatability of our bending operations exemplify our commitment to quality craftsmanship. Contact us to discuss how our bending solutions can be tailored to your project's needs.

Stamping:

During the stamping phase, our high-speed equipment shapes metal panels with impeccable accuracy. Custom dies, designed from your specifications, ensure that every stamped feature is precise and consistent. This process creates clean edges and well-defined contours, essential for the functionality and look of your server rack blank panels. Automated controls maintain exact pressure and timing throughout each stamping cycle, while skilled technicians monitor for any deviations. Our stamping process is a critical step in achieving the desired form and finish, laying the groundwork for a robust final product. We invite you to explore our stamping capabilities and see how we transform raw materials into precision components.

Welding:

In the welding stage, precision joining techniques are employed to secure panel components with robust and seamless bonds. Our automated welding systems, combined with skilled oversight, ensure consistent heat control and alignment, resulting in durable joints that meet your custom design requirements. This process is essential for reinforcing the structural integrity of the panels, ensuring that all components are securely connected. Each weld undergoes strict inspection protocols to confirm its strength and quality. Our commitment to precision welding guarantees that the final product is not only aesthetically pleasing but also built to withstand the rigors of daily use in demanding environments. Contact us to learn more about our welding process.

Surface Treatment:

Following welding, our surface treatment process enhances the durability and appearance of your custom panels. Advanced techniques such as cleaning, polishing, and coating are employed to protect the metal from corrosion and wear. Automated application systems ensure a uniform finish across every panel, while quality checks verify the smoothness and consistency of the treatment. This stage not only improves the product's visual appeal but also extends its lifespan, ensuring it remains functional and attractive over time. Our surface treatment process is tailored to meet your specific requirements, offering both protection and aesthetic value. Reach out to us today to discuss how our surface treatment capabilities can elevate your project.

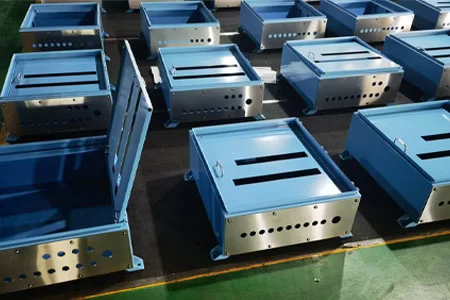

Assembly:

During assembly, individual components are meticulously combined to form the final Custom OEM Server Rack Blank Panels. Our automated assembly lines work in tandem with experienced technicians to ensure precise alignment and secure fastening of every part. Detailed assembly procedures and quality inspections guarantee that the panels meet your custom specifications. This stage is crucial for integrating all manufactured components into a cohesive, high-quality product. Our assembly process is streamlined to maintain efficiency without compromising on quality, ensuring that your custom panels are ready for installation and immediate use. Contact us to see how our assembly expertise can bring your vision to fruition with reliability and precision.

Packaging & Delivery:

During assembly, individual components are meticulously combined to form the final Custom OEM Server Rack Blank Panels. Our automated assembly lines work in tandem with experienced technicians to ensure precise alignment and secure fastening of every part. Detailed assembly procedures and quality inspections guarantee that the panels meet your custom specifications. This stage is crucial for integrating all manufactured components into a cohesive, high-quality product. Our assembly process is streamlined to maintain efficiency without compromising on quality, ensuring that your custom panels are ready for installation and immediate use. Contact us to see how our assembly expertise can bring your vision to fruition with reliability and precision.

After-sales Service:

Our commitment to customer satisfaction extends beyond production through our dedicated aftersales service. We offer prompt return, exchange, and replenishment services to ensure your complete satisfaction with every order. If you encounter any issues with your delivered panels, our responsive team will facilitate a hassle-free return or exchange process. Additionally, should you require additional stock, our replenishment service is designed to meet your ongoing needs swiftly. Please note that our aftersales service focuses solely on returns, exchanges, and replenishments, and does not include repair or system assembly support. Contact us anytime for reliable aftersales assistance and experience our unwavering dedication to service.