Our complete supply chain can provide electrophoresis, electroplating, hot dip plating, powder coating, passivation, anodizing, sandblasting, polishing, wire drawing, and other surface treatment services. Kindly contact us for more suitable solutions and

Supply Better Sheet Metal Surface Treatment Service

HULK Metal Surface Treatment Factory

-

Introduction

-

Equipment

-

Moments

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

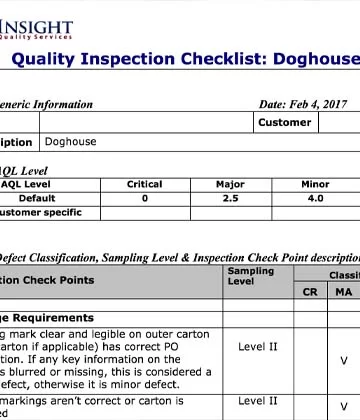

Surface treatment needs to complete tests on thickness, adhesion performance, wear resistance, impact resistance, corrosion resistance, antioxidant capacity in specific environments, raw material composition, dissipated odor, and other aspects according to requirements. Therefore, a factory that can provide high-standard surface treatment services needs to be equipped with an advanced and complete quality control center. We have close cooperation with surface treatment factories that can provide electrophoresis, powder coating, electroplating, hot dip plating, anodizing, sandblasting, shot blasting, polishing, wire drawing, and other surface treatment services. For sheet metal parts with special surface treatment requirements, we will develop a complete inspection plan and issue a detailed inspection report.

HULK METAL Surface Treatment Line

Shown here are the assembly lines and quality control center equipment we use to provide high-standard surface treatment services to our customers. They are more automated, efficient, and capable of completing higher-demand surface treatments. Kindly contact us to view them in person or online.

-

01Anodizing Production Line

Surface treatment lines are mainly aimed at aluminum sheet metal parts. We can customize the color, thickness, and accuracy of the surface of the sheet metal parts.

-

02Electro Galvanizing Line

Electro-galvanizing has a wide range of applications. It is brighter, more uniform, more precise, and more expensive than hot-dip galvanizing. Suitable for some decorative sheet metal parts.Electro-galvanizing has a wide range of applications. It is brighter, more uniform, more precise, and more expensive than hot-dip galvanizing. Suitable for some decorative sheet metal parts.

-

03Electrophoresis Line

This assembly line can achieve overall electrophoresis of sheet metal parts up to 2*4 meters. The coating is more even and complete.

-

04Hot Dip Coating Line

The most common materials for hot-dip plating are zinc and aluminum. And we only provide galvanizing services. Hot dip plating is suitable for steel or iron sheet metal parts with low surface quality requirements.

-

05Polishing Equipment

Polishing is suitable for stainless steel and aluminum sheet metal parts. We offer mirror polishing, semi-finish polishing, and rough polishing.

-

06Powder Coating Line

It can achieve spray painting of 3*3 meter sheet metal parts. Higher quality spraying and greater automation. The surface of your product is more beautiful and durable.

-

07Quality Control Center

Our quality control center can complete quality inspections such as surface treatment accuracy, thickness, adhesion, and usage environment simulation testing.

Surface Treatment Moment

Here is a picture showing our surface treatment process. We support online factory tours. Kindly contact us. We will introduce it to you in detail.

-

Detection

Test the hardness, thickness, roughness, and corrosion resistance of the surface.

-

Alkaline Cleaning & Acid Cleaning

Remove oil stains, impurities, and oxides from the sheet metal surface.

-

Polishing

Place the sheet metal part on the polishing machine and polish it in all directions.

-

Powder Coating Process

Hang the sheet metal parts on the assembly line in an orderly manner. After passing through the assembly line, pretreatment and spraying processes will be carried out by itself.

Process for Conducting Surface Treatment Services

Through perfect processes, you can experience different sheet metal manufacturing services. We separate the service process of surface treatment in sheet metal manufacturing so that you can better understand the process of surface treatment.

-

PART 01Custom Surface Treatment Solution Based on Requirement

PART 01Custom Surface Treatment Solution Based on RequirementThe experienced technical team will determine the appropriate surface treatment based on the complexity of the sheet metal parts and whether welding, machining, and assembly are required. They can also make more effective suggestions based on the material of the sheet metal parts, the use environment, etc., and finally determine the final solution with you.

-

PART 02Ultrasonic Cleaning

PART 02Ultrasonic CleaningSheet metal parts that are cut, stamped, welded, or riveted need to be blown away by strong wind to remove surface impurities. This prevents impurities from being trapped under the coating and causing protrusions that could damage the coating. The cost of this step is very high, and generally, only sheet metal parts made of expensive materials will use this treatment method.

-

PART 03Acid Cleaning or Alkaline Cleaning

PART 03Acid Cleaning or Alkaline CleaningUse pickling or alkaline cleaning to remove surface oil and existing oxide layers. This step will improve the adhesion of the coating to the sheet metal parts.

-

PART 04Surface Treatment

PART 04Surface TreatmentFactors such as material, purpose, usage environment, price, etc., jointly determine which surface treatment method to use. You can ask our sales manager what surface treatment services we can provide when placing an order.

-

PART 05Quality Control

PART 05Quality ControlWe will randomly check the surface adhesion, thickness, accuracy, appearance, corrosion resistance, and oxidation resistance of sheet metal parts. Each batch of orders comes with a test report.

-

PART 06Issue Test Report

PART 06Issue Test ReportA complete quality inspection report will accompany each batch of orders.

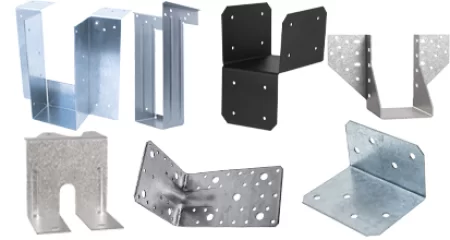

Sheet Matel Parts HILK Metal Have Produced

We have completed OEM services for hundreds of products for factories, buyers, and wholesalers in more than 20 industries. Here are some of the products we have OEMed. You can send us drawings to get the latest and more competitive solutions.

-

Trailer Tow Hitch Drop Plate Factory in China

Trailer Tow Hitch Drop Plate Factory in ChinaOur OEM Trailer Tow Hitch Drop Plate is generally made of high-performance carbon steel, which can withstand the weight and stress during towing. The finished product needs to pass strict random inspections to ensure the qualified rate.

READ MORE

-

Trailer Stake Pocket Manufacturer In China

Trailer Stake Pocket Manufacturer In ChinaHULK Metal is dedicated to providing excellent trailer stake pocket manufacturing services to numerous suppliers. We have an experienced technical team, an ISO 9001 and ISO 16949 certified sheet metal factory, and supporting logistics.

READ MORE

-

Boat Trailer Roller Brackets OEM Factory

Boat Trailer Roller Brackets OEM FactoryBy integrating a comprehensive supply chain, we are committed to providing high-quality OEM services for boat trailer roller brackets to each customer.We sincerely invite you to contact us for solutions and quotations.

READ MORE

-

Roof Bike Carriers For Cars Factory in China

Roof Bike Carriers For Cars Factory in ChinaIn order to firmly fix the bicycle on the roof, we need to consider the torsion resistance, impact resistance, and other performance that may cause deformation of the bike carriers at multiple angles.

READ MORE

-

Kayak Roof Rack OEM Service

Kayak Roof Rack OEM ServiceThe goal of our OEM Kayak Roof Rack is to be more durable and safer, and on this basis, control its cost. We hope to gain more customers through perfect services and high-quality products.

READ MORE

-

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

Custom Sheet Metal Parts For Construction

Custom Sheet Metal Parts For ConstructionWe provide more comprehensive services by vertically integrating the raw material, packaging, and freight, and horizontally integrating various sheet metal factories to produce better Sheet Metal Parts.

READ MORE

-

Metal Base Plate

Metal Base PlateHULK Metal has an ISO 9001-certified factory. We can develop complete production and quality inspection plans to provide high-quality metal base plate OEM services according to your requirements.

READ MORE

-

Concrete Embeds Steel Embed Plates

Concrete Embeds Steel Embed PlatesHULK Metal is committed to producing higher-quality steel embed plates through high-quality sheet metal manufacturing services. Kindly contact us for a better quotation.

READ MORE

More Results

Benefits of Choosing HULK Metal Surface Treatment

In addition to surface treatment services, we also provide cutting, stamping, welding, and other sheet metal manufacturing services, as well as packaging, transportation, and free freight consulting services. A perfect supply chain will bring you more benefits. Kindly read my details below.

-

Get Sheet Metal Parts With Higher Quality Surface

ISO 9001 certified sheet metal surface treatment factories, advanced surface treatment lines, and experienced workers are the basis for us to provide high-quality surface treatment services. Our quality control center strictly tests the materials used for surface treatment. We will complete the testing of surface adhesion, thickness, hardness, wear resistance, corrosion resistance, and oxidation resistance according to your requirements. Inspection reports will be provided with each batch of orders.

-

Get Goods Faster

Our technical team will develop a complete solution based on your requirements and shorten the lead time by reasonably arranging raw material procurement, production, quality inspection, packaging, and other links. Our logistics center can realize fast transportation from factory to cooperative factory, factory to warehouse, and warehouse to port. Freight consulting companies can find better cross-border shipping companies. You receive your goods faster through our supply chain.

-

Spend Less Money

We have integrated a complete supply chain to control the overall cost of orders. Through us, you can buy raw materials with better quality and lower price, order production costs can be effectively controlled, and packaging, logistics, freight, and other aspects can reduce objective costs. Customers often start placing additional orders after receiving their first shipment from us. Kindly contact us for a more suitable solution.

-

Spend Less Time & Energy

The cost of time and effort is priceless, and you save even more with HULK Metal. We have a service team that can help you solve your problems. They will take you to visit the factory online or on-site and explain the production process at the place of order. When you are unable to follow the production of your order in person, they will provide videos, pictures, and settings through video calls to make you immersed in the scene. We provide comprehensive after-sales service to properly solve quality problems.

Articles of Surface Treatment

Here is a collection of articles related to surface treatment such as types, their processes, testing, etc. We provide quality sheet metal fabrication services. Kindly send us your requirements. Our sales manager will lead the team to provide you with one-to-one service.