HULK Metal integrates stamping factories, surface treatment factories, and machining factories to form a complete supply chain to provide high-quality sheet metal stamping services. Kindly contact us for solutions and quotes if you have parts you need OEM

Supply Better Sheet Metal Blanking & Forming Service

Top Sheet Metal Stamping Service Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

Start Sheet Metal Stamping Services AT HULK METAL

When you choose HULK Metal as a stamping parts OEM, a team including technology, procurement, production, quality inspection, after-sales, and other members will provide one-to-one service. Kindly contact us if you need sheet metal stamping services. You can experience easier purchasing.

-

Factory:

HULK Metal's sheet metal stamping factory can complete the production of stamped parts using processes such as blanking, bending, spinning, deep drawing, and bulging. A laser cutting workshop can reduce material consumption and reduce time spent processing cuts. The CNC machining center can better complete the fine processing of sheet metal parts, and the welding shop can use a variety of welding processes to complete the assembly of stamping parts. The surface treatment factory can complete electrophoresis, anodizing, galvanizing, passivation, powder spraying, and other process requirements.

-

Experience:

We have provided hundreds of companies with thousands of products, such as car exterior modification accessories, trailer parts, fitness equipment accessories, and construction hardware. Developing time-saving and high-quality solutions based on drawings is the basic skill of our technical team. Completing production, quality inspection, packaging, delivery, and after-sales as required is what we must do. Give HULK Metal a chance, and you can experience different OEM services.

-

Quality:

Ensuring product quality is our original intention. ISO9001-certified factory, quality control center with advanced testing equipment, and strict quality inspection process all reflect our determination to provide customers with high-quality sheet metal stamping parts. We will not reduce the quality of raw materials to reduce costs, nor will we reduce the necessary production processes to shorten delivery time. Perhaps because of this, more and more customers choose HULK Metal and become our long-term partners.

-

Service:

We believe that thoughtful service can also help customers save costs because time and energy costs cannot be bought with money. We have developed service commitments to enable us to better serve our customers. There will be someone at HULK Metal to help you follow up on the entire order process and report in real-time. The comprehensive quality assurance service will provide returns, exchanges, and replenishments for any products with quality problems. Kindly contact us to start different OEM services.

Sheet Metal Stamping Services Capacities

You can see the range of capabilities of our sheet metal stamping services here. This table only includes OEM methods, raw materials, stamping processes, tolerances, machining capabilities, surface treatment capabilities, etc. Kindly contact us if you would like to learn more. You can directly send drawings, required quantity, and delivery method. We will use this to formulate complete solutions and quotations.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

PROCESS: | Bending / Spinning / Deep Drawing / Expansion / Flanging / Shrinking |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Sheet Metal Stamping Service

Here, you can see the entire process of our sheet metal stamping services. A detailed description cannot be given due to space constraints. Kindly contact us if you would like to learn more. Our service team will take you around the stamping factory and explain it to you in detail.

-

01

Get Drawings And Requirements

In order to better formulate production solutions and prices, we recommend that you send us 2D and 3D drawings, surface treatment methods of stamping parts, required quantities, and desired delivery methods as much as possible. We will sign an NDA to protect your privacy.

-

02

Custom Solutions

We formulate a first draft of the solution, discuss the feasibility with you, and then determine the final solution through an in-depth understanding of your needs. The entire order's raw material procurement, stamping parts production, quality inspection, packaging, delivery, and after-sales will all be carried out in an orderly manner.

-

03

Samples Producing & Testing

Once the final solution is determined, we will begin sample production and testing and send it to you for testing. After the sample passes the test, we will start to arrange the procurement of raw materials, order production, and packaging. To ensure that orders can be produced in a more orderly manner and delivered earlier.

-

04

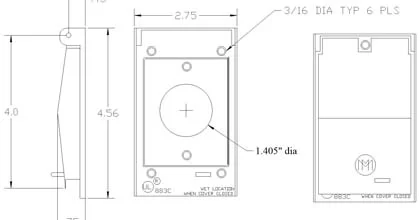

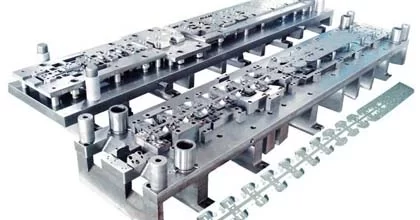

Mold Making

Stamping requires the use of stamping dies. There are many types of molds, the common ones are simplex molds, conforming molds, continuous molds, and transfer molds. According to the process, the molds can also be divided into punching molds, spinning molds, bending molds, etc. Experienced sheet metal stamping service providers will design more reasonable molds to reduce mold costs.

-

05

Laser Cutting

We will use laser cutting to cut aluminum, iron, steel, stainless steel, and other sheet metal into specific sizes and shapes for stamping use. We chose laser cutting because it has higher precision than plasma and flame cutting, the cutting seams are thinner, and the cut sheets do not require subsequent cleaning.

-

06

Sheet Metal Blanking

Use punches and punching dies to further punch, trim, and slit the cut materials. The blanking of composite molds and continuous molds will be performed synchronously or asynchronously with the forming process, allowing the production of stamped parts to be completed in one go, but the cost of such molds will be more expensive.

-

07

Sheet Metal Foaming

Use spinning dies, drawing dies, bulging dies and other simplex dies or composite dies to process the blanked sheet metal again. We can get finished products or semi-finished products.

-

08

Welding

Use welding methods such as brazing, fusion welding, and pressure welding to connect semi-finished stamping parts according to the drawings. Choosing the appropriate welding process and completing it by experienced welders can improve the overall quality of the order, reduce costs, and shorten the delivery time.

-

09

Machining

The mechanical processing step needs to be arranged before or after welding according to the production process arrangement. Mechanical processing mainly plays the role of drilling, tapping, surface quality adjustment, and shape adjustment in the production of stamping parts.

-

010

Surface Treatment

The surface treatment methods of stamping parts made of iron plates and steel plates are galvanizing, electrophoresis and powder spraying. Aluminum plates can be added with anodizing and sandblasting. Stainless steel plates can be added with chemical, PVD coating, sandblasting, mirror polishing, surface coloring, and surface drawing processes.

-

011

Overall Assembly

The above-stamped parts are assembled into a whole through riveting, screws, welding, and other linking methods. Three-dimensional sheet metal stamping parts can be assembled in the factory before being shipped without increasing transportation and packaging costs and are easier to assemble at the place of use.

-

012

Packaging

We have close cooperation with packaging manufacturing factories and can provide customization and appearance printing services for corrugated boxes, ordinary cartons, wooden boxes, and other boxes. You have more choices when it comes to packaging.

-

013

Delivery

Our logistics team can complete loading, transportation, port entry, and more faster. Realize seamless connection from factory to port, station, and air freight station. We have a strictly managed warehouse that can provide short-term cargo custody services. We can also help you consult with multiple freight companies. So you can compare prices.

-

014

After Service

We provide after-sales service after receipt of goods to ensure product quality. We will proactively handle every issue and find a win-win solution.

Parts Our Sheet Metal Stamping Service Produced

Here, you will see the sheet metal stamping parts we manufacture. We have provided sheet metal fabrication services to over 20 industries such as car modification, trailering, fitness equipment, construction, machinery manufacturing, etc. Kindly send the drawings to us. We will complete better orders according to your requirements.

-

Trailer Support Legs Factory in China

Trailer Support Legs Factory in ChinaWe have a complete trailer support legs supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide.

READ MORE

-

Trailer Coupler Factory In China

Trailer Coupler Factory In ChinaWe have an advanced sheet metal factory certified by ISO 9001 and ISO 16949 to meet your trailer coupler manufacturing needs. We provide customers with quality services through perfect supply chain management.

READ MORE

-

Roof Rack Connectors Factory In China

Roof Rack Connectors Factory In ChinaWe focus on providing customers with high-quality metal fabrication services. To this end, we have integrated high-quality factory resources and established a complete supply chain.

READ MORE

-

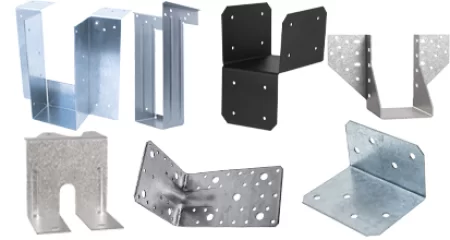

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

Custom Sheet Metal Parts For Construction

Custom Sheet Metal Parts For ConstructionWe provide more comprehensive services by vertically integrating the raw material, packaging, and freight, and horizontally integrating various sheet metal factories to produce better Sheet Metal Parts.

READ MORE

More Results

Metal Stamping Serice Types HULK Metal Can Supply

We can provide two types of sheet stamping services: sheet metal blanking and sheet metal forming. We will design reasonable processes and molds to achieve faster delivery of orders.

Sheet Metal Blanking

Sheet Metal Forming

Metal Bending Service

-

Sheet Metal Blanking

Install a sheet metal punching die on the punch machine, place the metal plate on the mold, and the upper and lower molds will form shearing force under the action of the punch machine to cut the plate into the desired shape. The blanking process can be used for blanking and punching. A simple stamping part is completed through this process. Some require a combination of sheet metal forming, welding, machining, and other processes to complete production. An excellent sheet metal stamping factory will have multiple punch machines with different working capabilities to adapt to the production of stamping parts of different materials and structures. We only need to replace the mold during the production process.

-

Sheet Metal Forming

Sheet metal forming is the continuous action of punching machines and molds, such as bending, drawing, bulging, and flanging, to make sheet metal parts with complex structures. Metal TV stands, car exterior accessories, and fitness equipment racks can all be produced using sheet metal forming. In many cases, similar to sheet metal blanking, the forming process needs to be combined with cutting machining, surface treatment, and other processes to manufacture sheet metal parts with better performance and more complex structures. An excellent sheet metal stamping factory will take you to visit the factory, introduce the production capabilities, and then formulate a complete solution and calculate the price according to your order.

-

Metal Bending Service

HULK Metal offers comprehensive metal bending services that convert your detailed designs into precision-engineered components. Our experienced team collaborates closely with clients to understand requirements and review drawings, ensuring every project is executed with exact tolerances. Utilizing advanced, high-capacity equipment, we deliver efficient production processes and consistently durable, high-quality finishes. Each step is monitored through stringent quality control protocols from initial consultation to final delivery, with dedicated after-sales support available to address any concerns. Trust HULK Metal for innovative, cost-effective metal bending solutions that meet the rigorous demands of modern fabrication.

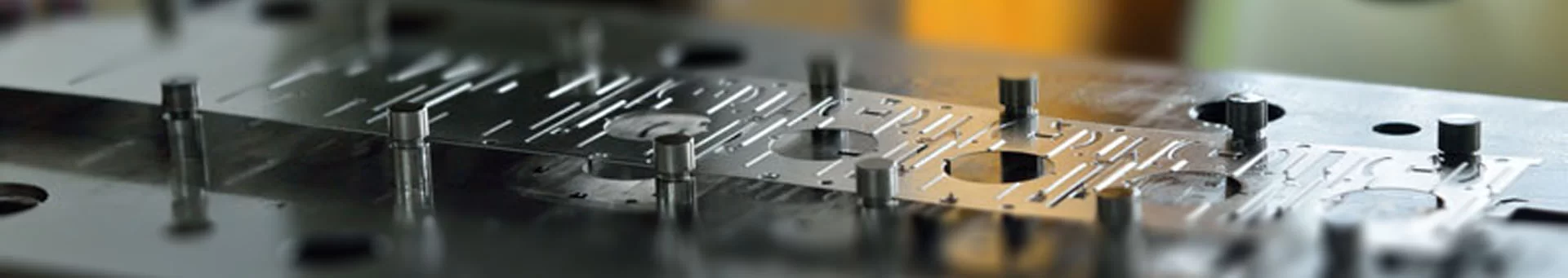

View Our Sheet Metal Stamping Factory

Here, you will see pictures of our sheet metal stamping factory equipment, quality inspection center, and production process. You can click and learn more or contact us. We will take you to visit the stamping factory to introduce it in detail and provide complete solutions and quotations.

-

Production Moment

The experienced production team can be more proficient in using punch machines, repairing molds, strictly abiding by production management, and completing the stamping process faster with quality and quantity.

-

QC Center

Our QC center has electron microscopes, hardness testers, impact testing machines, and salt spray testers to issue material and product testing reports according to your requirements.

-

Stamping Workshop

Our stamping workshop has more than 20 punch machines, which can complete punching and forming processes at the same time.

Sheet Metal Stamping Services Introduction

Here, you can learn more about the definition of sheet metal stamping services, which industries can use to produce parts, which materials can also be used to produce sheet metal parts, and the benefits you can get by choosing HULK Metal to produce sheet metal parts.

-

Sheet Metal Stamping Service Means

Sheet metal stamping services are metal manufacturing plants that use punching, bending, spinning, deep drawing, bulging, and other stamping processes to complete the production of sheet metal parts. In addition to the above services, excellent stamping factories also provide cutting, welding, assembly, surface treatment, packaging, warehousing, transportation, and other services, while most of them can only provide the above cutting, stamping, welding, and assembly services. sheet metal stamping services include OEM (customer-provided drawings) and ODM (factory design drawings). HULK Metal body is an OEM service.

-

Sheet Metal Stamping Service Application

Parts made from sheet metal can be manufactured by sheet metal stamping factories. sheet metal stamping parts can be found in every aspect of our lives. Parts of fitness equipment, cars, metal lockers, bicycles, range hoods, etc. all have sheet metal stamping parts. Many types of metals can be processed by sheet metal stamping. Common ones in daily life include aluminum, iron, carbon steel, stainless steel, copper, etc.

Choose HULK Metal As Your OEM Factory

HULK Metal will provide solutions, including solution customization, raw material procurement, cutting, stamping, machining, welding, assembly, packaging, warehousing, logistics, export freight consulting, and after-sales services. We can effectively shorten the order delivery cycle, lower the overall order cost, and reduce the energy and time you spend on the order through the complete supply chain. We hope to become leaders in each other's industries through joint efforts.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Article of Sheet Metal Stamping

Here, we have compiled a detailed introduction, including sheet metal stamping processes, materials, molds, applications, etc. And what kind of sheet metal stamping service provider can help you save costs, etc. Of course, you can contact us directly.