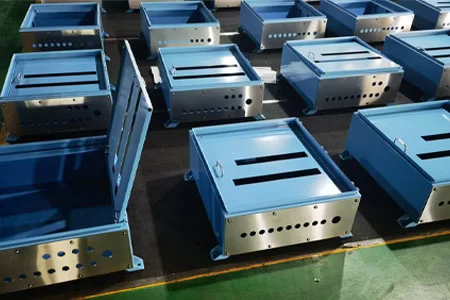

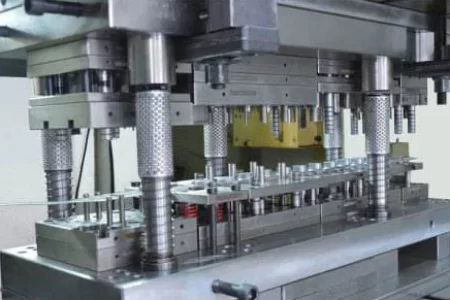

HULK Metal has ISO 9001 and ISO 16949-certified sheet metal factories to provide you with laser cutting, bending, stamping, welding, and assembly services. A complete supply chain can help you save more time, energy, and money to complete procurement task

HULK Metal is a Chinese sheet metal parts manufacturer with rich production experience.

Provide Excellent Custom Sheet Metal Parts OEM Service

Industries

-

- Stone Fixing Brackets Factory In China

- Custom Sheet Metal Brackets

- Wood Framing Connectors

- Steel Beam Clamps

- Precast Concrete Accessories

- Custom Sheet Metal Parts For Construction

- Post to Beam Connector

- Metal Beams Brackets

- Metal Base Plate

- Concrete Embeds Steel Embed Plates

- Angle Iron Connectors Construction Hardware

-

- Roof Rack Connectors Factory In China

- Universal Roof Rack Crossbars Factory in China

- Roof Bike Carriers For Cars Factory in China

- Pickup Truck Bed Accessories OEM Factory

- Pickup Truck Roll Bars OEM Factory

- Kayak Roof Rack OEM Service

- Cargo Baskets

- Car Bike Racks

- Heavy Duty Roof Racks

- Metal Roof Racks

-

- Trailer Tow Hitch Drop Plate Factory in China

- Winch Post for Boat Trailer Factory in China

- Trailer Tire Carrier Factory In China

- Trailer Support Legs Factory in China

- Trailer Stake Pocket Manufacturer In China

- Trailer Hitch Mount Factory in China

- Trailer Coupler Factory In China

- Boat Trailer Roller Brackets OEM Factory

- Boat Trailer Bunk Brackets Factory in China

- Boat Trailer Brackets Manufacturer In China

-

- Custom Wall Mount Network Rack

- Heavy Duty Network Server Cable Management

- Custom OEM Server Rack Blank Panels

- Custom Network Server Tray

- Wall Mount Network Racks

- Network Server Rack Tray Brackets

- 1U 2U 3U 4U Server Rack Blank Panels

- 18 to 47U Network Server Cabinets

- Network Server Rack Cable Management

- 18 to 47U Network Server Rack

-

- Laser Cutting Metal Parts Factory

- OEM Server Switch Rack Enclosure Cabinet

- Custom Metal Brackets Factory In China

- Carbon Steel Stamping Parts Factory in China

- Sheet Metal Spinning Parts Factory In China

- Stainless Steel Stamping Parts Factory In China

- Aluminum Stamping Parts Factory In China

- Sheet Metal Parts Manufacturer In China

- Precision Metal Stamping Parts Manufacturer

- OEM Auto Metal Stamping Parts Factory

- Stamped Steel Parts Factory

- Metal Stamping Parts Factory

- China OEM Metal Stamping Parts

-

Features

-

Capacities

-

Description

-

Factories Visit

-

Benefits

-

Articles

-

Review

-

Top