Processes of Complete 18 to 47U Network Server Cabinets:

Our comprehensive production process transforms your detailed drawings into a high-quality, fully customizable server cabinet. Every phase—from initial planning to after-sales support—is executed with precision to meet your exact specifications. Reach out today to receive your custom production plan and quote!

Develop a Production Solution Based on the Drawings:

Once we receive your detailed design drawings, our engineering team meticulously reviews every specification to develop a tailored production plan. This plan outlines the entire manufacturing process, including material selection, dimensional tolerances, and quality checkpoints. By collaborating closely with you, we ensure that the plan reflects your vision and anticipates any potential challenges. Our structured approach guarantees that each step—from design validation to production feasibility—is clearly mapped out, providing a solid foundation for subsequent operations. This proactive planning phase not only minimizes risks but also streamlines production, ensuring that your custom cabinet is produced accurately and efficiently. Contact us now to discuss your design and let our experts create a roadmap for success!

Mold Making:

Following plan approval, our skilled technicians utilize advanced CAD software and precision machining tools to design and produce high-quality molds. These molds are crafted to replicate every detail of your server cabinet design, ensuring consistent and accurate production. Each mold undergoes rigorous testing and calibration to confirm that it meets our strict quality standards before entering full-scale production. This essential step ensures that all subsequent parts are formed with precision, reducing variability and guaranteeing a perfect fit for your custom specifications. Reach out to learn more about our mold-making process and how it guarantees the fidelity of your design!

Sample Trial Production and Adjustment:

With the molds finalized, we initiate a trial production run to create sample cabinets. These samples are thoroughly inspected for dimensional accuracy, structural integrity, and finish quality. Any discrepancies identified during this phase prompt immediate adjustments to our molds or process parameters. This iterative process continues until the sample meets every requirement outlined in your design. Once the sample is approved, we lock in the production settings for full-scale manufacturing, ensuring that every cabinet produced will meet the same high standards. Contact us today to learn how our sample trial process ensures perfection in every unit!

Quality Control Plan Formulation:

After sample approval, our dedicated quality control team formulates an extensive quality control plan tailored specifically to your project. This plan includes stringent inspection protocols at every production stage—from raw material verification to final product testing. Our real-time monitoring systems and regular audits help catch any deviations early, ensuring consistent product quality. Detailed checklists and precise measurement tools are utilized to confirm that each cabinet meets your exact specifications. By integrating quality control into every step of the process, we provide you with a product that is both reliable and robust. Reach out now to discover more about our proactive quality control measures!

Production Scheduling:

Our project managers develop a detailed production schedule that coordinates every phase of manufacturing to meet your delivery timelines. This schedule strategically allocates resources, synchronizes workflow across all departments, and includes buffer periods for quality inspections. Our systematic scheduling ensures that each process transitions smoothly, minimizing downtime and maximizing efficiency. Whether you require a rapid turnaround for a small order or have a large-scale production run, our scheduling system is designed to adapt to your needs while maintaining stringent quality standards. Contact us to discuss your timeline and see how our scheduling expertise can expedite your project!

Raw Material Procurement:

We source only premium-grade raw materials from trusted suppliers to ensure the longevity and reliability of your server cabinets. Every batch of material is rigorously tested for consistency and compliance with your design specifications. Our established relationships with top-tier suppliers enable us to secure high-quality materials at competitive prices, contributing to both performance and cost efficiency. This careful selection process forms the foundation of our manufacturing excellence, ensuring that every cabinet is built to last under demanding conditions. Get in touch to learn more about our raw material procurement process and its impact on product quality!

Laser Cutting:

During the cutting phase, our advanced automated equipment precisely slices raw materials according to your design dimensions. Computer-controlled systems ensure that each cut is uniform and minimizes waste, providing a solid foundation for subsequent manufacturing processes. Skilled operators continuously monitor the cutting process to ensure that every piece meets the exact tolerances specified in your design. This critical step guarantees that the components are accurately prepared for further processing, setting the stage for a flawless final product. Contact us today to explore how our cutting technology ensures precision in every component!

Bending:

After cutting, the materials are transferred to the bending phase, where state-of-the-art bending machines form them into the required shapes and angles. Automated controls combined with skilled technician oversight ensure that every bend adheres to the precise tolerances dictated by your design. Continuous monitoring and quality checks throughout this process guarantee that the structural integrity of each component is maintained. This stage is essential for creating the ergonomic and functional form of your server cabinet. Reach out now to learn how our bending process creates flawless, custom-fit components for your project!

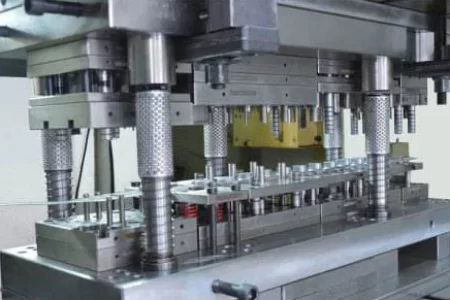

Stamping:

In the stamping phase, precision presses are employed to imprint detailed features and cutouts into the metal components of your cabinet. Computer-controlled stamping machines ensure that every mark is consistent and meets the strict design criteria. This process not only enhances the structural strength of the components but also contributes to the overall aesthetic appeal of the final product. Rigorous in-process inspections guarantee that each stamped detail is executed with precision. Contact us to discuss our stamping capabilities and how they ensure the excellence of your custom cabinet!

Welding:

Following stamping and bending, welding operations join various components to form a cohesive and robust server cabinet structure. Utilizing a blend of automated welding systems and skilled manual techniques, we ensure that every weld is strong, uniform, and meets strict quality standards. Each weld is inspected for integrity and appearance, ensuring that the final product can withstand the operational stresses of a data center environment. This critical step cements the durability and reliability of your cabinet. Get in touch to learn more about our welding process and quality verification methods!

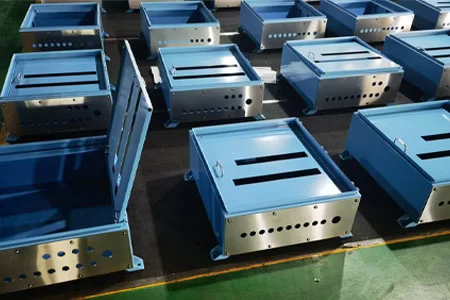

Surface Treatment:

Once the cabinet structure is assembled, it undergoes an advanced surface treatment process to enhance durability and aesthetic appeal. Utilizing eco-friendly coatings and state-of-the-art finishing techniques, we apply a protective layer that resists corrosion and wear. Each cabinet is carefully inspected to ensure the finish is smooth, uniform, and free of defects. This process not only extends the life of your cabinet but also provides a professional, polished look that elevates your data center's appearance. Contact us today for more information on our surface treatment options and benefits!

Assembly:

In the assembly phase, all pre-processed components are meticulously combined to form the final 18 to 47U Network Server Cabinet. Our assembly line integrates automated precision with expert craftsmanship to ensure that every part fits together seamlessly. Multiple quality checkpoints are in place to verify that each assembled cabinet meets your specific design requirements and functions perfectly in its intended environment. This comprehensive assembly process results in a product that is both reliable and aesthetically superior. Reach out now to learn more about our assembly process and how we ensure flawless integration!

Packaging & Delivery:

Once fully assembled and inspected, each cabinet is carefully packaged using custom-designed materials to ensure maximum protection during transit and storage. Our packaging process includes secure wrapping, detailed labeling, and robust protection against environmental factors. This final step is critical to ensure that your custom cabinet arrives in pristine condition, ready for installation. Our packaging methods are optimized for both safety and efficiency, providing you with peace of mind. Contact us to learn more about our secure packaging solutions and logistics services!

After-sales Service:

Our commitment to excellence extends beyond production with a comprehensive after-sales service designed to support you throughout the cabinet's lifecycle. We offer expert technical support, installation guidance, and maintenance services to ensure that your 18 to 47U Network Server Cabinet continues to perform at its best. Our dedicated customer service team is available to address any issues, provide timely advice, and facilitate any necessary repairs or adjustments. This ongoing support helps build long-term partnerships and ensures your complete satisfaction. Get in touch today for reliable, responsive after-sales service and continuous support!