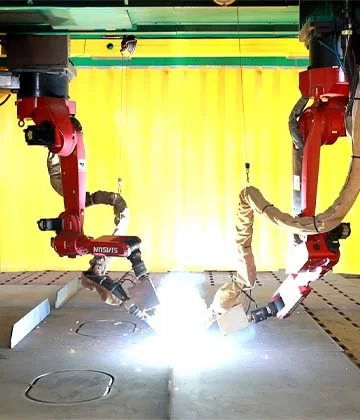

HULK Metal has advanced arc welding, laser welding, gas welding, resistance welding, and other welding equipment. Experienced welders can complete welding with higher quality requirements. The quality inspection center can complete a full range of welding

To Supply More Sheet Metal Fabrication Service

Advanced Sheet Metal Welding Center

-

Introduction

-

Equipment

-

Moments

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

We usually choose the more appropriate one from fusion welding, pressure welding, and brazing based on the material, structure, assembly method, and welding performance requirements of the sheet metal parts to complete the welding of the parts and the overall assembly. We will choose strict random inspection methods and develop a complete quality inspection process. The welding qualification rate can reach 99.9%. We welcome every customer to visit the factory and see our welding process and quality inspection process with their own eyes. We also support online factory tours. You can visit the production site from your office. In addition to welding, our supply chain can also provide services such as cutting, stamping, surface treatment, packaging, and transportation.

With such a complete service, wouldn’t you think that the price would be very high? Others, it is not. Do not believe? Contact us at Kindly to get prices that will surprise you.

HULK METAL Welding Equipment

In this section, we present the equipment of our welding center. One of the reasons we can provide quality sheet metal welding services is because of this advanced equipment. You can contact us to visit the factory on-site or online. We will give you a detailed introduction and plan a more suitable solution and quotation based on your requirements.

-

01Argon Arc Welding Machine

We use it to complete single-sided and double-sided forming welding of 6~10mm thin sheet metal parts and thick plates.

-

02Digital Ultrasonic Testing Device

Complete the inspection of internal pores, cracks, and other defects in the weld and promptly discover unqualified welding parts.

-

03Resistance Welding Machine

It can weld sheet metal parts made of carbon steel, stainless steel, aluminum, and other materials. Experienced welding masters can use it to weld high-quality parts.

-

04Laser Welding Machine

We will use it to complete some sheet metal welding parts that require higher welding accuracy, appearance, and performance.

Sheet Metal Welding Moment

Here, we show the process of our welding masters completing the welding of sheet metal parts, the appearance of the welds, and the process of weld inspection. We offer complete sheet metal fabrication services. Kindly contact us to visit the factory and get the latest quotation.

-

Argon Arc Welding Process

the process of an experienced master operating a tig welding machine.

-

Details Of Argon Arc Welding Seam

Arc welding can weld thicker sheet metal parts with good welding performance.

-

Laser Welding Process

Laser welding has a higher degree of automation and higher welding efficiency.

-

Laser Welding Seam Details

Laser-welded sheet metal parts below 10mm have more beautiful welds and higher precision.

-

Spot Welding Process

This is the process in which our welding masters use spot welding to complete the assembly of sheet metal parts.

How Is HULK Metal’s Welding Service Carried Out?

Welding is one of the most important processes in sheet metal manufacturing. It welds cut and stamped semi-finished products together to form a complete stamped part or a component of another product. You can find out more about our services here. Kindly contact us for service details.

-

PART 01Choose Suitable Welding Process

PART 01Choose Suitable Welding ProcessWhen we receive your drawings and samples, we will choose a more suitable one from many welding processes based on material, plate thickness, welding performance, appearance requirements, etc.

-

PART 02Sheet Metal Parts Cutting & Stamping

PART 02Sheet Metal Parts Cutting & StampingAfter the order starts production, we will first use a laser cutting machine to complete the pre-cutting of the plate. And then use stamping to complete the deformation of the sheet metal as needed.

-

PART 03Welding

PART 03WeldingWelding of small batches and small sheet metal parts usually involves spot welding, laser welding, or argon arc welding. Submerged arc welding can be used for welding large and thick sheet metal parts. Choosing the right welding process can save a lot of costs.

-

PART 04Quality Control

PART 04Quality ControlThe quality control center will detect the structure, defects, mechanical properties of the welds, and other inspections required from you. We will issue a comprehensive inspection report.

-

PART 05Machining

PART 05MachiningThe appearance of the weld is further processed using mechanical processing.

-

PART 06Surface Treatment

PART 06Surface TreatmentWe can provide electrophoresis, powder coating, galvanizing, passivation, and other surface treatment services. Aluminum sheet metal parts can be anodized. Stainless steel sheet metal parts can be polished or brushed.

-

PART 07Packaging

PART 07PackagingWe have close-knit packaging factories that can provide higher-quality paper, wooden boxes, as well as anti-collision filling.

-

PART 08Delivery

PART 08DeliveryOur warehousing center can realize flexible connections from factory to factory, factory to warehouse, and warehouse to freight port. The freight consulting team can also help you find a more suitable freight company.

-

PART 09After Service

PART 09After ServiceWe provide complete after-sales service. We will give you a satisfactory solution if there are quality problems with the goods.

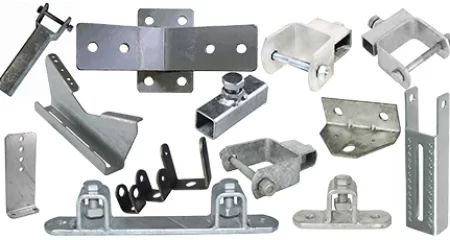

Sheet Metal Parts HULK Metal Have Welded

We have produced sheet metal parts for more than 20 industries, including automobile exterior decoration, trailer manufacturing, construction hardware, fitness equipment manufacturing, etc. We will develop a more suitable solution and a price that satisfies you based on your drawings and requirements.

-

Trailer Tire Carrier Factory In China

Trailer Tire Carrier Factory In ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Hitch Mount Factory in China

Trailer Hitch Mount Factory in ChinaWe have a sheet metal manufacturing facility certified by ISO 9001 and ISO 16949, capable of providing high-quality OEM services for your trailer hitch mounts. Our integrated supply chain ensures the efficient completion of every order.

READ MORE

-

Boat Trailer Roller Brackets OEM Factory

Boat Trailer Roller Brackets OEM FactoryBy integrating a comprehensive supply chain, we are committed to providing high-quality OEM services for boat trailer roller brackets to each customer.We sincerely invite you to contact us for solutions and quotations.

READ MORE

-

Boat Trailer Brackets Manufacturer In China

Boat Trailer Brackets Manufacturer In ChinaWe can use this component to construct a "V" structure on the trailer to secure the boat. It consists of three primary parts: the trailer connection, the support rod, and the support head.

READ MORE

-

Pickup Truck Roll Bars OEM Factory

Pickup Truck Roll Bars OEM FactoryThe goal of our OEM Kayak Roof Rack is to be more durable and safer, and on this basis, control its cost. We hope to gain more customers through perfect services and high-quality products.

READ MORE

-

Cargo Baskets

Cargo BasketsIt is a storage expansion placed on the roof of SUVs, Cars, or Trucks, used to store and fix luggage, tents, sports tools, and other facilities that cannot be placed inside the car.

READ MORE

-

Heavy Duty Roof Racks

Heavy Duty Roof RacksIts load capacity is stronger than ordinary roof racks. Therefore, its material requirements are more stringent. Even if it is made of the same material, its production thickness will be thicker.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesWe can produce a full range of Spread Anchors, wire loop boxes concrete embeds, and other precast concrete accessories produced using cutting, stamping, welding, and other processes.

READ MORE

-

Post to Beam Connector

Post to Beam ConnectorHULK Metal focuses on providing high-quality sheet metal manufacturing services to global sheet metal purchasers. So far, we have produced millions of items of more than a dozen types for customers.

READ MORE

-

Concrete Embeds Steel Embed Plates

Concrete Embeds Steel Embed PlatesHULK Metal is committed to producing higher-quality steel embed plates through high-quality sheet metal manufacturing services. Kindly contact us for a better quotation.

READ MORE

More Results

CHOOSE HULK METAL WELDING YOU WILL GET

Many customers think our prices are higher before placing an order. After working together, they chose to place more orders with us. It may be the following four points that make them trust us more and more.

-

Get Higher Quality Sheet Metal Parts

We can produce higher quality sheet metal parts. Our quality control center will develop a complete testing plan based on your requirements. CMM, tensile tester, impact testing machine, hardness tester, ultrasonic flaw detector, and other testing instruments can complete the testing of various properties of sheet metal parts. We will inspect the raw materials, semi-finished products, and finished products of each batch of orders and issue a comprehensive quality inspection report. Higher-quality sheet metal may become one of your key selling points.

-

Get Goods Faster

Technical staff will develop more appropriate solutions and shorten the order delivery time as much as possible by arranging production links reasonably. Experienced workers can skillfully operate and maintain cutting, stamping, and welding equipment. Orders can be produced efficiently and with high quality. The logistics team can achieve efficient transportation from factory to factory, factory to warehouse, and warehouse to destination port. The Freight Consultation Center can help you find a more suitable freight company. The perfect process allows us to get the order into your hands as quickly as possible.

-

Spend Less Money

Many customers save a lot of costs by using our supply chain. The biggest role of a complete supply chain is that it can save costs from all links through unified coordination. As the number of orders increases, the supply chain can operate efficiently for a long time. Your order can save more costs in terms of raw materials, molds, production, packaging, logistics, labor, time, etc.

-

Spend Less Time & Energy

We will help you save the most valuable time and energy through services that match the supply chain. We have established a service team, including raw material procurement, technology, production, quality inspection, packaging, and other personnel. They will be coordinated by the sales manager who is in contact with you to help you solve any problems. You can also keep track of the status of your order through our real-time feedback service.

Articles of Metal Welding

We have compiled some articles about metal welding so that you can better understand this process. You can also find some particularly interesting content here, such as how to choose a better metal fabricator, tips from welders, etc.