Our sheet metal manufacturing facility features advanced CNC machining centers. Use high-precision tools for trimming, drilling, and tapping to make sheet metal parts more beautiful and precise. Kindly contact us for more satisfactory solutions and quotat

To Supply More Precise and Beautiful Sheet Metal Parts

Sheet Metal Machining Factory

-

Introduction

-

Equipment

-

Moments

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

Use milling cutters, turning tools, drills, and other tools to complete the processing of the edges, surfaces, shapes, and structures of sheet metal parts. Using CNC machining machines can further improve the accuracy of sheet metal parts. When it is determined that the accuracy of sheet metal parts really requires CNC machining to adjust, we will develop a more reasonable solution by measuring material costs and production costs such as cutting, stamping, welding, and time costs. This can reduce costs without affecting product quality. Our CNC machining center has more than 20 five-axis, four-axis, and three-axis CNC machine tools that can meet the production needs of various large-volume orders. Kindly contact us to visit the sheet metal machining factory.

Sheet Metal Machining Factory Equipment

We briefly introduce to you the equipment of our machining center in the form of pictures and text. Choosing more appropriate CNC processing equipment based on the complexity of the sheet metal structure can save more costs. You can contact us to make an appointment to visit the factory online or on-site.

-

01Four-Axis Machining Equipment

We have five four-axis CNC machining equipment, which can be programmed to achieve more complex surface processing.

-

02Five-Axis Machining Equipment

Five-axis machining centers can process more complex curved surfaces than four-axis machining centers.

-

03General Processing Machine Tools

Drilling, tapping, polishing, and other processing can be completed efficiently.

-

04Three-Axis Machining Equipment

We have more than a dozen three-axis CNC machining centers that can complete the three-dimensional processing of sheet metal parts by programming multiple single-sided programming solutions.

Machining Factory Moment

Our team of workers is experienced and can skillfully complete sheet metal fixing, programming operations, equipment maintenance, etc. We also have graphic and text methods to simply display the relevant content of the website.

-

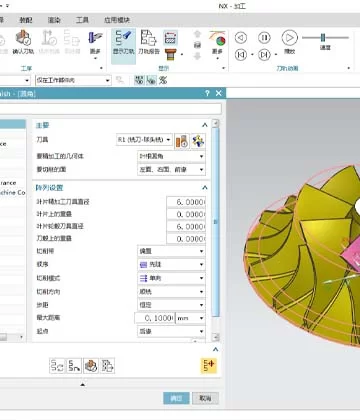

Program Adjusting

Select programming based on the processing surface of the sheet metal part.

-

Milling

Surface accuracy and tolerances are adjusted using milling processes.

-

Programming

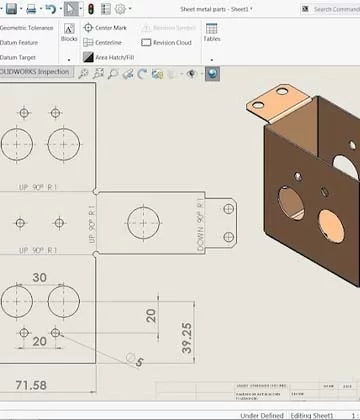

Technicians perform CNC programming according to the drawings.

-

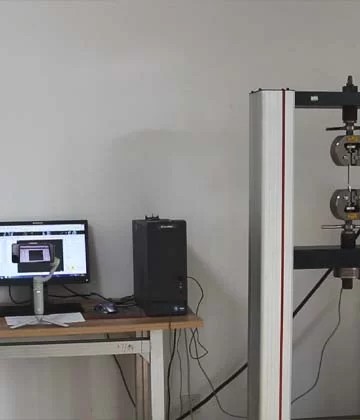

Quality Control

The quality control center tests various properties of sheet metal.

-

Turning

Use a turning process to adjust the edges of sheet metal parts.

Process We Machining Your Sheet Metal Parts

Our sales managers will have an in-depth understanding of your needs, and our technical team will develop perfect solutions based on your needs. We have refined the common processes of CNC machining and presented them below. Kindly contact us if you would like to know how your product is produced.

-

PART 01Custom Solution Based on Drawings

PART 01Custom Solution Based on DrawingsOur sales manager will lead the team to deeply understand your needs and develop perfect solutions. The solution will include the approximate time and total cost of raw material procurement, production, packaging, transportation, etc. You need to send us the drawings, quantity and delivery method, packaging requirements, and other information as comprehensively as possible.

-

PART 02Programming

PART 02ProgrammingWhen formulating the solution, we determined which machining center to use to complete the sheet metal parts. Technicians will use CAD and other programming software to complete programming and import it into the CNC center.

-

PART 03Cutting

PART 03CuttingLaser cutting is used to cut large pieces of sheet metal to specific sizes. Some metal parts are produced after the cutting edges are processed. Some cutting parts also need to go through the stamping process.

-

PART 04Stamping

PART 04StampingStamping is a complex process. We have a detailed introduction to stamping services. You can click directly to learn more or contact us, and our engineers will explain it in detail.

-

PART 05Machining

PART 05MachiningThe operator will fix the sheet metal parts, operate the CNC terminal, and select the appropriate program to complete the processing of the sheet metal parts. Common processing methods include turning, milling, drilling, grinding, etc.

-

PART 06Quality Control

PART 06Quality ControlWe need to detect the tolerances, surface accuracy, etc., of the sheet metal during the processing and after processing.

Sheet Metal Parts Hulk Metal Have Machined

We have provided sheet metal machining services to more than 20 industries, such as construction hardware, fitness equipment accessories, trailer accessories, automobile exterior accessories, etc. We display some of our products here. Kindly send drawings and requirements to us. We will work out a solution that makes you more satisfied.

-

Trailer Tow Hitch Drop Plate Factory in China

Trailer Tow Hitch Drop Plate Factory in ChinaOur OEM Trailer Tow Hitch Drop Plate is generally made of high-performance carbon steel, which can withstand the weight and stress during towing. The finished product needs to pass strict random inspections to ensure the qualified rate.

READ MORE

-

Trailer Tire Carrier Factory In China

Trailer Tire Carrier Factory In ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Stake Pocket Manufacturer In China

Trailer Stake Pocket Manufacturer In ChinaHULK Metal is dedicated to providing excellent trailer stake pocket manufacturing services to numerous suppliers. We have an experienced technical team, an ISO 9001 and ISO 16949 certified sheet metal factory, and supporting logistics.

READ MORE

-

Boat Trailer Roller Brackets OEM Factory

Boat Trailer Roller Brackets OEM FactoryBy integrating a comprehensive supply chain, we are committed to providing high-quality OEM services for boat trailer roller brackets to each customer.We sincerely invite you to contact us for solutions and quotations.

READ MORE

-

Pickup Truck Bed Accessories OEM Factory

Pickup Truck Bed Accessories OEM FactoryWe have a complete pickup truck bed accessories supply chain to provide you with high-quality OEM services. We can develop a complete solution based on the drawings and specific requirements you provide. We provide a complete QA Service.

READ MORE

-

Heavy Duty Roof Racks

Heavy Duty Roof RacksIts load capacity is stronger than ordinary roof racks. Therefore, its material requirements are more stringent. Even if it is made of the same material, its production thickness will be thicker.

READ MORE

-

Precast Concrete Accessories

Precast Concrete AccessoriesWe can produce a full range of Spread Anchors, wire loop boxes concrete embeds, and other precast concrete accessories produced using cutting, stamping, welding, and other processes.

READ MORE

-

Metal Beams Brackets

Metal Beams BracketsHULK Metal can provide high-quality metal beams brackets because our sheet metal factory has advanced cutting machines, stamping, and welding equipment, experienced workers, and QC center.

READ MORE

More Results

Our Metal Machining Can Do For You

We hope to make it easier to complete your order purchase by providing complete sheet metal machining services. The following four aspects are what we will insist on doing. We believe you will gain even more from HULK Metal.

-

Higher Quality Sheet Metal Parts

We will strictly implement ISO 9001 quality management and have strict testing procedures in every link, from sample trial production to raw material procurement to mass production. A small mistake at the beginning will cause major quality accidents in the future, so we will develop a complete testing process according to your requirements and conduct strict testing from the beginning. We will prepare material and finished product inspection reports for each order.

-

Deliver Goods Faster

The technical team will select more suitable CNC processing equipment and develop more reasonable solutions according to your requirements. Experienced technicians can skillfully complete sheet metal parts fixing, program switching, prop replacement, and other processes. The above are the reasons why we can shorten the lead time. Our logistics center can quickly deliver goods to various locations. The Freight Consultation Center can help you find a better freight company to complete the delivery of your goods.

-

Save More Money

A complete supply chain gives us the ability to control order costs as a whole. When the order quantity is larger, we can obtain cheaper and higher quality raw materials from raw material suppliers with whom we have close cooperation. A more reasonable production process can save more time, labor, and other costs. Owned logistics centers and freight consultation centers can eliminate the cost of middlemen.

-

Save More Time & Energy

You can save more priceless time and energy with us. Our sales manager will lead a service team, including purchasing, production, quality inspection, logistics, freight company consultation, and after-sales personnel to help you solve problems in the purchasing process. They will give you feedback on the progress of your order using pictures, videos, and video calls. We will be responsible for the quality of each product. Any of your problems can be solved properly.

Articles of Sheet Metal Machining

We have compiled more articles about sheet metal processing for you to read. They include sheet metal materials, CNC processing-related content, and some sharings from our engineers. You can contact us to learn more or get a solution that is more suitable for you.