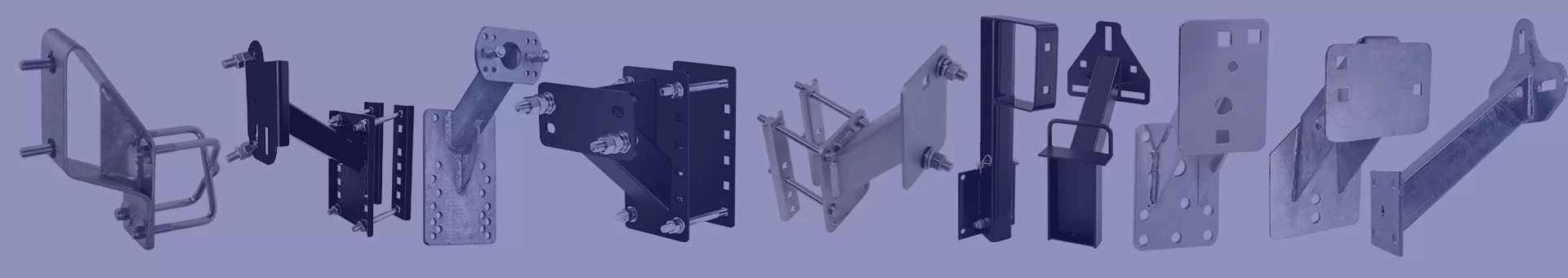

How Trailer Tire Carrier are Produced:

The materials of trailer tire carriers are varied, including iron pipes, carbon steel pipes and stainless steel pipes. Through precise cutting and superb welding techniques, we assemble these materials into a sturdy large frame. We briefly introduce the possible production processes so that you can better understand our manufacturing process. We welcome you to contact us, make an appointment to visit our factory, and tailor a satisfactory solution for you.

Get a Deeper Understanding Of Your Requirements:

Our sales manager will work with the service team to communicate with you in depth, fully understand your needs, and tailor a complete solution for you accordingly. To make our preparations more thorough, please provide the following information in advance:

1. Drawings or samples of trailer tire carriers so that we can accurately understand your technical requirements and design standards.

2. Order quantity, required materials, and expected surface treatment methods to help us estimate costs and capacity planning.

3. Your specific requirements for product packaging to ensure the safety and protection of the product during transportation.

4. Delivery method and expected delivery cycle so that we can arrange production and logistics plans.

In addition, please also let us know any other information you think is helpful to us. We look forward to communicating with you and are committed to providing you with the best service.

Make Molds & Programming:

Before the order is launched, we carefully design the stamping and bending molds according to the drawings to ensure that every detail meets your requirements. We maintain a close cooperative relationship with the mold manufacturer, which not only enables us to obtain more durable molds at a more favorable price, but also guarantees production efficiency and product quality.

Make Samples & Testing:

Before mass production, we will rehearse the production process and produce samples. This process is crucial because it allows us to fine-tune the process before actual production begins, ensuring that we can produce high-quality trailer tire carriers while maximizing cost-effectiveness. We will send you samples for your testing and evaluation. This not only guarantees the quality of the final product, but also ensures that your needs are met.

Quality Control:

We are well aware of the importance of product quality, so we have developed a strict testing program based on the product's qualification rate requirements, performance standards, and appearance specifications. Our quality control process starts with raw materials, ensuring that each batch of raw materials undergoes rigorous physical and chemical property testing before production to prevent any unqualified materials from entering the production line.

At the semi-finished product stage, we test the mechanical properties to ensure that each component meets the specified performance standards before assembly. After assembly, our quality control team will conduct another comprehensive test to verify that all indicators of the finished product, including function, durability, and appearance, meet the established requirements.

To ensure transparency and traceability, we will provide detailed test reports for each batch of orders, recording the test results at every step from raw materials to finished products. In this way, you can rest assured that your product has been thoroughly inspected and meets the highest quality standards.

Production Scheduling:

Once the sample passes the test, we will act quickly and reasonably deploy the equipment, personnel and other resources in the factory to ensure that your order can be completed as quickly as possible. Our efficient production process and flexible resource management ensure that while ensuring product quality, we can also meet your strict requirements for delivery time.

Cutting:

We are equipped with 4 fully automatic laser cutting machines. These advanced equipment can quickly and accurately complete the cutting of plates, tubes and profiles with a maximum thickness of 30mm. Through efficient operation, we have laid a solid foundation for subsequent processes and ensured the smoothness and efficiency of the entire production process.

Stamping:

We have a 500-ton punching machine that can quickly produce complex sheet metal parts using progressive dies. For simpler stamping parts, we use 60-110-ton punching machines with compound and single-pass dies for efficient production. In addition, we are equipped with the latest bending machines specifically for the production of pipe parts to ensure that every detail meets the precise design requirements. Our equipment strength and technical capabilities will provide you with fast and high-quality production services.

Machining:

We use advanced tapping machines, CNC machining centers and polishing machines to complete the holes and threads of trailer tire carriers. These high-tech equipment ensures the accuracy of each hole and thread, as well as the smoothness of the surface, meeting the highest standards. Through precise processing processes, we not only improve production efficiency, but also ensure the quality and durability of the products. Choosing us, you will be guaranteed fine workmanship and perfect performance.

Welding:

We have introduced advanced resistance welding machines, argon arc welding machines and laser welding machines to ensure the accuracy and efficiency of the welding process. Our welding masters are experienced and proficient in a variety of welding techniques, including fish scale welding, spot welding and pull welding. They can choose the appropriate welding techniques according to the requirements of different components to ensure that each welding point is firm and reliable. For large-volume orders, we can quickly deploy welding robots and set up efficient welding production lines to improve production speed and consistency. At the same time, we are equipped with ultrasonic flaw detectors and magnetic particle flaw detectors. These professional testing equipment are used to ensure that the welding quality meets the highest standards.

Surface Treatment:

We have a fully automated powder coating line that provides high-quality powder coating services. In addition, we have established close partnerships with hot-dip galvanizing, electro-galvanizing, electrophoresis and other surface treatment factories. Through these partners, we can provide you with higher quality surface treatment services and meet your needs at a more favorable price. Our professional team will ensure that each surface treatment process meets your specifications and adds value and durability to your products.

Assembly:

Once all parts production and procurement are completed, our assembly line will start efficiently, quickly and accurately completing the assembly of the trailer tire carrier. Our assembly line design is optimized to ensure that each link can proceed smoothly, thereby improving production efficiency and shortening delivery time. Our professional assembly team will ensure that every detail meets quality standards to provide you with a complete trailer tire carrier.

Packaging:

To ensure that the surface treatment of the product is optimally protected during transportation, we select high-quality fillers based on specific requirements. These fillers effectively absorb shock and vibration, preventing the product from being damaged during transportation.

For outer packaging, we offer corrugated box packaging, which is a sturdy and cost-effective packaging solution suitable for a variety of transportation environments. In addition, we also provide bulk options for those situations where additional packaging is not required or the customer wishes to pack it themselves. Regardless of the packaging method, our goal is to ensure that your product arrives at its destination safely and intact.

Delivery:

We have a professional logistics center and international freight consulting center, which can provide you with fast and safe cargo transportation services. No matter where your cargo is going, we can ensure that the cargo is delivered on time and in good condition. Our professional team has rich logistics experience and can recommend and arrange the most suitable freight company for you according to your specific needs.

After-sales Service:

As one order is successfully completed, another new order cycle begins. We firmly believe that only by continuously providing high-quality products and meticulous services can we win the trust of customers and a steady stream of orders. To this end, we have formed a perfect service team, ready to help you solve various problems at any time.

We welcome you to contact us at any time and give us the opportunity to show you our professional capabilities and service level. No matter what challenges you face, we will do our best to provide you with the most satisfactory solutions.