HULK Metal will select the more suitable one from flame cutting, plasma cutting, and laser cutting according to your drawings and requirements, so as to complete the order with lower cost and higher quality.

Supply Better Sheet Metal Cutting Service

Top Sheet Metal Cutting Service Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

Start Sheet Metal Cutting Services at HULK METAL

HULK Metal selects the appropriate cutting process from a variety of cutting processes based on the thickness of the metal plate, the precision of the cutting parts, and the complexity of the shape to reduce order costs and shorten delivery times. Kindly contact us if you need factory-completed sheet metal cutting services.

-

Sheet Metal Cutting Machinery:

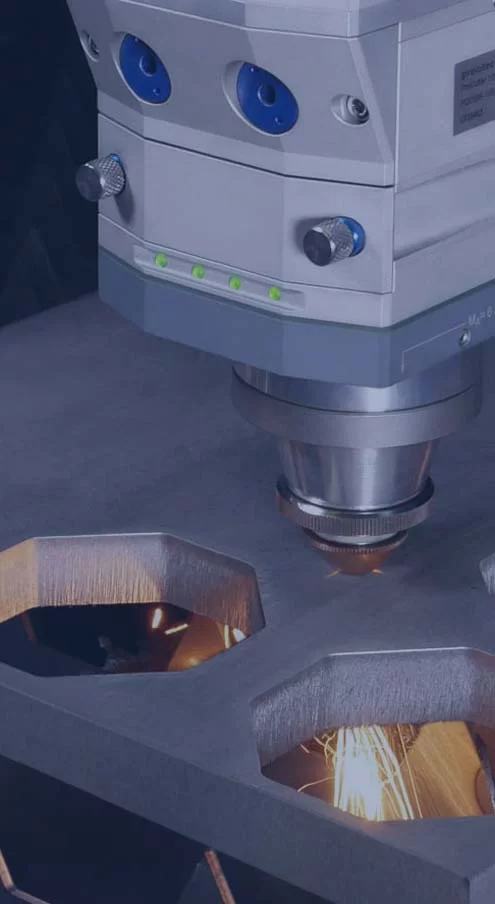

HULK Metal has a fully automatic laser cutting machine that can realize automatic cutting of sheet metal through programming. The laser cutting accuracy can reach 0.2mm, and the cutting seam is 0.1 mm~0.3 mm, which can improve material utilization. The cuts are smooth and flat, requiring almost no secondary processing. It will be more advantageous to cut metal plates within 8mm. We will use a plasma cutting machine to cut metal plates above 8mm because it will be more advantageous.

-

Experience:

Choosing the appropriate sheet metal cutting process to complete sheet metal parts with different requirements can save costs. For sheet metal parts with low precision requirements and small shapes, the blanking process can be used to manufacture multiple pieces at one time, which is faster and more efficient. For those with high precision requirements and complex shapes, CNC laser cutting can be used. The finished product cut by laser has less deformation and higher precision. We will choose a more suitable process to complete the cutting of sheet metal parts based on the drawings and requirements.

-

Quality:

We have an advanced quality control center that can detect product materials, shapes, tolerances, and mechanical properties, etc. ISO 9001-certified factories have stricter production management. We will develop strict testing procedures and issue complete material and product testing reports based on your requirements. We also attach great importance to service quality because high-quality service can make it easier for you to complete your purchase and save more energy and time.

-

Services:

Our service team can help you solve quality, raw material procurement, production, surface treatment, quality inspection, packaging materials and design, warehousing, physics, freight company finding, and other issues during the order procurement process. We provide quality assurance services for returns, exchanges, and replenishments. We will implement our service purpose and continuously improve our service capabilities and quality to help you save more time and energy.

Shett Metal Cutting Services Capacities

HULK Metal can provide professional sheet metal cutting services. You can judge whether we can complete your order based on the information in the table below. This table includes materials, tolerances, machining processes, MOQ, etc. Kindly send us the drawings. We will provide you with solutions and quotations as soon as possible.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

SHEET METAL THICKNESS: | <=30mm |

PROCESS: | Laser Cutting / Plasma Cutting / According to Drawings |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / According to Drawings & Materials |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process Of Our Sheet Metal Cutting Service

Here, we describe how HULK Metal uses sheet metal cutting processes to fulfill your order. Sheet metal cutting can produce plate products with complex shapes that may be deformed using the punching process. Kindly contact us if you want to know more about them. Our sales manager will take you to visit our factory on-site or online.

-

01

Get Drawings And Requirements

After receiving your drawings and requirements, we will determine some information that may not be on the drawings through multiple communications, such as material, surface treatment, packaging, delivery method, etc.

-

02

Custom Solutions

We will continue to improve our solutions during the process of communicating with you to cover problems after order production and delivery. Solutions guide us to complete orders faster and deliver higher quality orders.

-

03

Programming

Our programmers will complete the programming of the laser cutting machine according to the drawings and according to the thickness, width, material, cutting seams, and other requirements of the sheet metal. The laser cutting machine can complete the cutting of the entire steel plate, and the material cost can be saved by rationally arranging the position of the sheet metal cutting parts on the plate.

-

04

Samples Making & Testing

We will complete the trial production of samples according to the solution process to ensure repeatability during mass production. Samples will be sent to you for testing. We will arrange bulk purchase of materials and order production after the samples pass the test.

-

05

Bulk Laser Cutting

Place the metal plate on the cutting table of the fully automatic laser cutting machine. The operator will run a preset program to complete the production of sheet metal cut parts. Laser-cut sheet metal parts have smooth cutting seams and higher precision. Even parts that require high precision in edge trimming only need to leave a small processing allowance.

-

06

Machining

Use machining processes to trim, thread, ream, polish, etc. sheet metal cutting parts. To achieve tighter tolerances and surface and precision.

-

07

Surface Treatment

The surface treatment methods of stamping parts made of iron plates and steel plates are galvanizing electrophoresis and powder spraying. Aluminum plates can be added with anodizing and sandblasting. Stainless steel plates can be added with chemical, PVD coating, sandblasting, mirror polishing, surface coloring, and surface drawing processes.

-

08

Packaging

For stainless steel and aluminum sheet metal parts with high surface precision, such as brushed, polished, and anodized, they can be coated (higher price) or packed with bubble pad isolation. We also support packaging box material and appearance customization.

-

09

Delivery

Our logistics team can complete loading, transportation, port entry, and more faster. Realize seamless connection from factory to port, station, and air freight station. We have a strictly managed warehouse that can provide short-term cargo custody services. We can also help you consult with multiple freight companies to facilitate you to compare prices.

Parts HULK Metal Cutting Service Produced

We have provided sheet metal cutting services for more than 20 industries, such as automobile exterior decoration, trailers, fitness equipment, construction hardware, etc. These are schematics of the products we have produced. You can send us the drawings. Our sales manager will communicate the details with you and develop a more suitable solution.

-

Cargo Baskets

Cargo BasketsIt is a storage expansion placed on the roof of SUVs, Cars, or Trucks, used to store and fix luggage, tents, sports tools, and other facilities that cannot be placed inside the car.

READ MORE

-

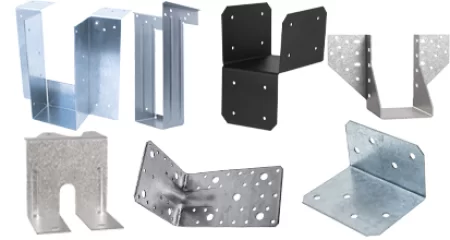

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

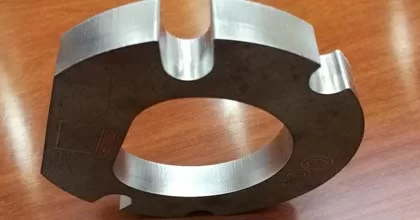

Post to Beam Connector

Post to Beam ConnectorHULK Metal focuses on providing high-quality sheet metal manufacturing services to global sheet metal purchasers. So far, we have produced millions of items of more than a dozen types for customers.

READ MORE

-

Metal Base Plate

Metal Base PlateHULK Metal has an ISO 9001-certified factory. We can develop complete production and quality inspection plans to provide high-quality metal base plate OEM services according to your requirements.

READ MORE

-

Angle Iron Connectors Construction Hardware

Angle Iron Connectors Construction HardwareWe can produce Angle Iron Connectors with thicknesses below 15mm. We can develop a more suitable solution based on your requirements and drawings.

READ MORE

More Results

Sheet Metal Cutting Serice Types HULK Metal Can Supply

We provide plasma and laser cutting services. Laser cutting has all-round advantages when cutting plates below 3cm, while plasma cutting has greater advantages when cutting cheap plates with a thickness of more than 3cm.

Sheet Metal Plasma Cutting

Sheet Metal Laser Cutting

-

Sheet Metal Plasma Cutting

We will consider using plasma cutting when cutting metal plates larger than 30mm and welding after cutting because the cutting seam of this cutting process can be used as a weld seam with only a small amount of processing. Its machines cost less and are more efficient at cutting thick plates. Because its slit is much wider than that of laser cutting, cost-effectiveness needs to be considered comprehensively when cutting precious metals (such as stainless steel).

-

Sheet Metal Laser Cutting

Our laser cutting service has provided OEM services for more than 20 industries, such as metal sheet metal parts that are not suitable for manufacturing abrasive tools, such as sheet metal parts with complex outlines, small batches, and general thicknesses of 6~12mm, decoration, etc. In addition, most plate stamping parts also need to go through the cutting process, such as construction hardware, fitness equipment accessories, trailer parts, automobile exterior accessories, etc.

View HULK Metal Cutting Factory

Here, we will show our cutting equipment and workers’ working moments in the form of pictures. Kindly Contact Us If you want to know about our production capabilities and have an order that requires cutting processing, our colleagues will take you to visit the factory.

-

Laser Cutting Program Setting

The operator sets up the fully automatic program. After the setting is completed, the cutting machine can automatically complete the cutting of a whole piece of metal plate.

-

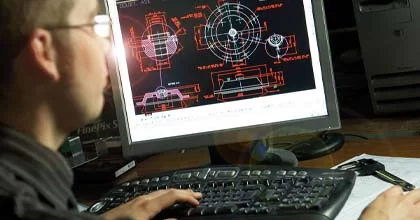

Cutting Diagram Drawing

Technicians use CAD to draw cutting drawings for import into the fully automatic laser cutting machine.

-

QC Center

Equipped with electron microscopes, hardness testers, impact testing machines, and salt spray testers to issue material and product testing reports according to your requirements.

-

Sheet Metal Cutting Workshop

The fully automatic laser cutting machine can quickly complete the cutting of sheet metal parts below 30mm.

-

Laser Cutting Moment

The cutting seams of laser cutting are very fine, and the precision is very high. Sheet metal parts using high-value metals can save a lot of material costs.

Sheet Metal Cutting Services Introduction

We hope you have a better understanding of metal-cutting services. Here, our metal cutting process, the advantages and disadvantages of cutting, and its applications are introduced in more detail. If you want to know more, you can check out our related articles.

-

Sheet Metal Laser Cutting

The laser cutter of the laser cutting machine can emit a high-power and density laser beam. This beam can quickly melt the metal plate when it is irradiated and use coaxial high-speed airflow to blow away the molten material on the surface of the cutting seam. The dimensional accuracy of laser cutting can reach ±0.05mm, and the surface roughness is only tens of microns. There is almost no change in the metal properties around the slit. Cutting metal plates with a thickness of 3cm can still ensure high accuracy. Laser cutting is suitable for processing metal sheet metal parts that are not suitable for making abrasive tools, such as sheet metal parts with complex outlines, small batches, and general thickness of 6~12mm, stainless steel patterns, marks, and fonts used in decoration, advertising, service industries, etc., as well as requirements Special parts for even cutting seams.

-

Sheet Metal Plasma Cutting

When the plasma gas returns to its normal state, it will release energy and generate a high temperature of 2700°C. Plasma cutting machines use this principle to use high-frequency arcs to decompose air or a mixture of hydrogen, argon, and nitrogen into "plasma". The high-pressure gas blows these plasmas out of the cutting torch burner, and the plasma quickly returns to its normal state and releases a high temperature to melt metal. The high-pressure air jet blows away the molten metal. Plasma cutting can cut metal plates with a thickness of 3~80mm. Plasma cutting will form a "V" shape. This cut is very convenient for laser welding.

Choose HULK Metal As Your OEM Factory

HULK Metal will provide solutions, including solution customization, raw material procurement, cutting, stamping, machining, welding, assembly, packaging, warehousing, logistics, export freight consulting, and after-sales services. We can effectively shorten the order delivery cycle, lower the overall order cost, and reduce the energy and time you spend on the order through the complete supply chain. We hope to become leaders in each other's industries through joint efforts.

When you choose HULK Metal as your sheet metal fabricator, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Article of Sheet Metal Cutting

Here we have compiled relevant articles about metal cutting. When we know more clearly how much this thing is worth, we can get a more accurate quote.