This comprehensive guide examines the factors to consider when selecting a metal stamping OEM factory in China. It covers production processes, material requirements, product applications, and partner selection criteria so you choose a facility that meets

Gain in-depth insights into key production, material, and partner selection factors when choosing a metal stamping OEM factory in China.

Critical Factors to Consider When Choosing the Right Metal Stamping OEM Factory in China

Metal Stamping OEM Factory in China

Critical Factors to Consider When Choosing the Right Metal Stamping OEM Factory in China

Metal stamping is a pivotal manufacturing process that transforms flat sheets of metal into intricately formed components through precision dies and controlled presses. For companies seeking a reliable partner—especially when searching for "Metal Stamping Factories In China"—choosing the right OEM (Original Equipment Manufacturer) is critical. This guide provides an exhaustive overview of the essential factors you must evaluate when selecting a metal stamping OEM factory. We cover everything from production processes, mold design, and process flow to material requirements, product applications, and partner selection criteria. By following these guidelines, you can optimize your production efficiency and ensure superior quality for your products.

If HULK Metal is mentioned, please note that they focus solely on delivering high-precision sheet metal stamping services. Their after-sales support is dedicated exclusively to handling returns, exchanges, or replenishments for quality issues or insufficient shipments. Production equipment is discussed only in terms of its advanced production capability.

Below, we present detailed sections addressing each critical aspect.

1. Introduction to Metal Stamping OEM Factories

1.1 What is Metal Stamping?

Metal stamping is a manufacturing process in which flat sheets of metal are transformed into finished components using dies and presses. During stamping, the metal sheet undergoes a series of operations—such as blanking, bending, piercing, flanging, and embossing—to produce parts that meet precise design specifications. The process relies on controlled deformation and plastic flow, which allow the metal to assume complex shapes with consistent quality.

In modern production, deep integration with computer numerical control (CNC) systems has significantly increased the precision and repeatability of stamping operations. With CNC controls, parameters such as force, speed, and blank holder pressure are carefully regulated to ensure uniformity and minimize defects like wrinkling, tearing, and springback. The result is a cost-effective process that minimizes waste while delivering high-quality parts.

1.2 The Role of OEM Factories in Metal Stamping

OEM factories that specialize in metal stamping serve as critical partners in global supply chains. They possess the technical expertise, advanced production equipment, and robust quality control systems needed to manufacture components for diverse industries. For companies considering "Metal Stamping Factories In China," OEM partners in China offer competitive pricing, high production capacities, and extensive industry experience.

1.3 Scope of This Guide

This guide is organized into five major sections:

- Production-Related Knowledge:

Covering mold design, production processes, process flow, common challenges, and advanced techniques.

- Material-Related Knowledge:

Exploring various materials used in stamping, their requirements, and best practices.

- Product-Related Content:

Detailing product applications with examples in server systems, trailers, automobiles, and building prefabrication.

- Partner Selection Factors:

Outlining the critical criteria for selecting the right metal stamping OEM factory.

- Conclusion:

Summarizing key takeaways to help you make an informed decision.

By the end of this guide, you will have a deep understanding of the production, material, and operational factors necessary to choose the ideal metal stamping OEM factory in China.

2. Production-Related Knowledge in Metal Stamping

Producing high-quality stamped components begins with a well-designed production process. In this section, we explore the entire production process in detail, including mold design, process flows, the integration of different stamping operations, and strategies to overcome common challenges.

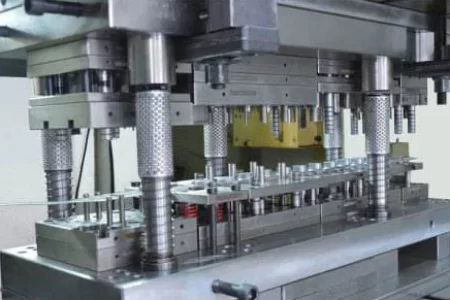

2.1 Mold Design and Its Importance

2.1.1 The Role of Mold Design

The mold is the core of any metal stamping operation. It defines the final shape, dimensions, and quality of the product. A high-quality mold ensures that the metal is formed with minimal waste, reduced cycle times, and consistent quality. The design of the mold directly influences stress distribution in the metal and determines the likelihood of defects such as wrinkling or tearing.

2.1.2 Key Components of a Stamping Mold

A stamping mold typically consists of three main components:

- Die:

The cavity that shapes the metal.

- Punch:

The tool that applies force, pressing the metal into the die.

- Blank Holder:

A device that holds the metal sheet in place, controlling the flow of material during stamping.

Each of these components must be designed with precision. The clearance between the punch and the die, the geometry of the die cavity, and the force exerted by the blank holder are all critical factors that influence the quality of the final product.

2.1.3 Design Considerations

Engineers use computer-aided design (CAD) and finite element analysis (FEA) software to simulate the stamping process before fabricating the mold. These tools help predict stress concentrations, potential deformation, and the risk of defects. By iterating on the design virtually, engineers can optimize the mold to achieve uniform wall thickness, reduce the risk of cracking, and minimize material waste.

2.2 Detailed Process Flow in Metal Stamping

2.2.1 Blank Preparation

The production process begins with preparing the metal sheet:

- Cutting:

Metal sheets are cut into blanks of the appropriate size and shape.

- Inspection:

Blanks undergo thorough quality checks to ensure consistency in thickness and surface quality.

- Cleaning:

The blanks are cleaned to remove oils, dust, and other contaminants that could affect the stamping process.

2.2.2 Clamping and Positioning

Once the blank is prepared, it is loaded into the stamping press:

- Loading:

The blank is positioned accurately on the die.

- Clamping:

Advanced clamping systems hold the blank securely. Proper clamping prevents movement and ensures uniform material flow.

- Alignment:

Operators use precision tools to confirm that the blank is correctly aligned with the die, which is essential for achieving accurate bends and cuts.

2.2.3 Stamping Operations

The stamping process itself comprises several operations:

- Blanking:

The initial step involves cutting the blank from a larger sheet.

- Forming:

The blank is then formed into the desired shape by the punch pressing it into the die cavity.

- Bending:

In some cases, additional bending operations are required to achieve the final geometry.

- Piercing and Embossing:

Features such as holes, cutouts, or embossed patterns may be added in subsequent operations.

- Trimming:

Excess material is removed to achieve the final dimensions of the part.

2.2.4 Process Combinations and Multi-Stage Operations

For complex parts, a single stamping operation may not be sufficient:

- Multi-Stage Drawing:

Parts with high depth or intricate geometries may require multiple drawing stages, sometimes with intermediate annealing to restore ductility.

- Combination Processes:

Deep drawing can be combined with bending, ironing, or piercing to create parts with complex features. This integration allows for greater flexibility and the production of high-quality components.

2.2.5 Common Production Challenges

Despite technological advances, several issues can arise:

- Wrinkling:

Caused by uneven metal flow; controlled by optimizing blank holder force.

- Cracking:

Occurs if excessive force is applied or if the metal's ductility is exceeded.

- Springback:

The tendency of metal to return partially to its original shape; often compensated by over-stamping.

- Tool Wear:

Repeated high-force operations can degrade tools; preventive maintenance is key.

2.2.6 Solutions and Advanced Techniques

To mitigate these challenges, manufacturers employ:

- Simulation Software:

FEA and CAD tools predict issues and allow for adjustments before production.

- Real-Time Monitoring:

Integrated sensors monitor force, temperature, and deformation, enabling dynamic adjustments.

- Preventive Maintenance:

Regular calibration and maintenance of machines ensure consistent performance and extend tool life.

- Skilled Operators:

Even with automation, experienced technicians are crucial for fine-tuning the process and managing unexpected issues.

2.3 The Role of CNC and Automation in Metal Stamping

2.3.1 CNC Integration

CNC stamping presses have revolutionized production by offering precise control over all aspects of the stamping process. Parameters such as force, speed, and blank holder pressure are pre-programmed and adjusted in real time, ensuring consistent quality across every part produced.

2.3.2 Automation Benefits

Automation minimizes human error, increases throughput, and enables high-volume production with minimal variation. Automated feedback systems continuously adjust process parameters to maintain optimal conditions, resulting in fewer defects and lower production costs.

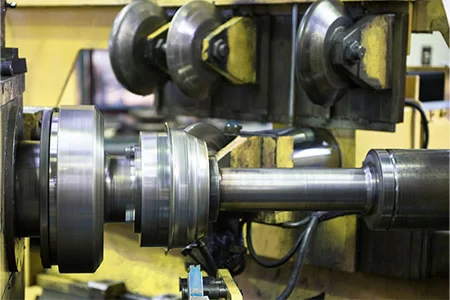

2.4 Production Equipment Capabilities

While specific brands are not mentioned, state-of-the-art metal stamping equipment is characterized by:

- High Throughput:

Capable of rapid cycle times to meet large-scale production demands.

- Robust Clamping Systems:

Ensuring that metal blanks are securely held during operations.

- Precision Force Application:

Delivering consistent, high-accuracy force for forming parts.

- Integrated Sensors:

Providing real-time data on pressure, temperature, and deformation for dynamic process control.

2.5 HULK Metal's Metal Stamping Service Capabilities

Companies like HULK Metal are recognized for their advanced metal stamping services. Their facilities are equipped with cutting-edge stamping presses that combine high production capacity with precision CNC controls. HULK Metal focuses on delivering components that meet stringent quality standards. If any quality issues or shipment discrepancies arise, their after-sales service is dedicated exclusively to managing returns, exchanges, or replenishments for products with quality problems or insufficient quantities.

2.6 Summary of Production-Related Knowledge

In conclusion, the production process in metal stamping is a complex, multi-stage operation requiring advanced mold design, precise blank preparation, sophisticated CNC integration, and rigorous quality control. Overcoming challenges such as wrinkling, cracking, and springback through simulation, real-time monitoring, and preventive maintenance is critical to achieving consistent, high-quality production outcomes.

3. Material-Related Knowledge for Metal Stamping

The choice of material is a cornerstone of metal stamping. The material's properties—such as ductility, strength, and thickness—directly affect its performance during stamping and the quality of the final component.

3.1 Importance of Material Selection

A successful stamping operation requires materials that can undergo extensive plastic deformation without fracturing. Key properties include:

- Ductility:

The material must be able to stretch and form without cracking.

- Strength:

It should maintain structural integrity after forming.

- Uniform Thickness:

Consistency in thickness is crucial for predictable deformation.

- Surface Quality:

A smooth, defect-free surface is necessary to achieve a high-quality finish.

- Work Hardening:

Materials with moderate work hardening are ideal to avoid uneven deformation.

3.2 Common Materials in Metal Stamping

3.2.1 Aluminum

- Advantages:

Lightweight, excellent corrosion resistance, and high ductility. Ideal for applications where weight reduction and intricate designs are desired.

- Requirements:

Must be of uniform thickness and temper; precise control over blank holder force and lubrication is essential to prevent over-thinning.

3.2.2 Stainless Steel

- Advantages:

Offers superior strength, durability, and attractive finishes. Used in applications requiring high structural integrity.

- Requirements:

Lower ductility necessitates higher forming forces; advanced process control is needed to avoid cracks and ensure uniform wall thickness.

3.2.3 Brass and Copper

- Advantages:

Valued for their electrical and thermal conductivity and aesthetic appeal. Highly malleable and suitable for decorative components.

- Requirements:

Prone to work hardening; require specialized lubricants and controlled stamping speeds to maintain consistency and reduce tool wear.

3.2.4 Mild Steel

- Advantages:

Cost-effective, with good strength and formability; widely used in industrial applications.

- Requirements:

Must be used in a controlled temper to avoid cracking; post-stamping surface treatments such as painting or powder coating often needed to enhance corrosion resistance.

3.3 Surface Treatments and Finishing Processes

Surface treatments significantly enhance the appearance and durability of stamped parts:

- Polishing:

Enhances the metal's natural luster and smoothness.

- Anodizing:

Commonly applied to aluminum for improved corrosion resistance and decorative finish.

- Powder Coating:

Provides a robust, uniform protective layer that increases wear resistance and aesthetic appeal.

3.4 Temperature Control and Lubrication

During stamping, temperature and lubrication play critical roles:

- Cooling Systems:

Maintain optimal temperatures to prevent overheating and excessive thinning.

- Lubricants:

Reduce friction between the metal and forming tools, ensuring smooth material flow and extending tool life.

3.5 Quality Assurance of Raw Materials

Ensuring raw material quality is essential for achieving consistent stamping results:

- Inspection and Testing:

Rigorous testing of incoming materials for uniform thickness, composition, and surface quality.

- Supplier Standards:

Working with reputable suppliers who meet industry standards ensures reliability.

3.6 Customization and Material Optimization

Manufacturers can sometimes tailor materials to better suit the stamping process:

- Alloy Adjustments:

Modifying alloy compositions can improve ductility or strength as needed.

- Pre-Treatment Processes:

Pre-heating or chemical treatments may be applied to optimize material properties before stamping.

3.7 Summary of Material-Related Knowledge

In summary, the success of metal stamping hinges on the careful selection and management of materials. Understanding the unique properties and requirements of aluminum, stainless steel, brass, copper, and mild steel allows for the optimization of process parameters and the achievement of high-quality, defect-free components. Effective surface treatments, temperature control, and proper lubrication further enhance the performance and longevity of stamped products.

4. Product-Related Content: Applications of Metal Stamping

Metal stamping is a versatile process that produces components used in a wide range of industries. In this section, we list and describe products in key categories. (High-end applications such as aerospace and nuclear power are excluded.)

4.1 Server-Related Products

Metal stamping is critical in the design and manufacture of components for server systems, where precision and uniformity are paramount.

4.1.1 Racks

- Server Racks:

Stamped frameworks that securely hold server equipment.

- Network Racks:

Racks designed specifically for networking hardware.

- Blade Server Racks:

Optimized for high-density blade server configurations.

- Rack Enclosures:

Protective stamped enclosures for sensitive electronics.

- Modular Racks:

Configurable frameworks that accommodate varying server sizes.

4.1.2 Cabinets

- Server Cabinets:

Secure, stamped enclosures that house servers and networking devices.

- Cooling Cabinets:

Cabinets engineered for optimal airflow and thermal management.

- Utility Cabinets:

Versatile cabinets used for housing ancillary server components.

- Cable Management Cabinets:

Enclosures that incorporate cable routing solutions.

- Lockable Cabinets:

Stamped for enhanced security and restricted access.

4.1.3 Brackets

- Mounting Brackets:

Essential for securing servers in racks.

- Accessory Brackets:

For supporting additional peripherals.

- Cooling Brackets:

To facilitate the installation of cooling systems.

- Adjustment Brackets:

Allowing for fine-tuning the positioning of components.

- Support Brackets:

Designed to provide structural reinforcement.

4.1.4 Trays

- Server Trays:

Flat, precision-formed trays for holding servers.

- Cable Trays:

For organizing and routing cables within data centers.

- Utility Trays:

Multipurpose trays used in various configurations.

- Cooling Trays:

Designed to improve airflow within server enclosures.

- Maintenance Trays:

Easily removable trays for efficient servicing.

4.1.5 Cable Management and Blank Panels

- Cable Management Systems:

Comprehensive solutions for secure cable routing.

- Cable Organizers:

Components that bundle and protect cable assemblies.

- Blank Panels:

Pre-formed panels for customized server enclosures.

- Ventilation Panels:

Stamped panels with perforations to enhance cooling.

- Utility Blank Panels:

Standard panels for various assembly requirements.

4.2 Trailer-Related Products

Trailers demand robust components produced through precise metal stamping for both structural integrity and aesthetic appeal.

4.2.1 Trailer Frames and Chassis Components

- Frame Rails:

Stamped elements forming the primary structure of trailers.

- Crossmembers:

Reinforcing bars that ensure overall frame rigidity.

- Chassis Components:

Key parts that support and distribute load.

- Structural Supports:

Additional stamped braces for enhanced strength.

- Reinforcement Plates:

For critical stress areas in trailer structures.

4.2.2 Side Panels and Enclosures

- Side Panels:

Curved stamped panels that form the sides of trailers.

- Cab Enclosures:

Stamped components for trailer cabins providing durability and style.

- Underbody Shields:

Protective covers that guard against road debris.

- Roof Panels:

Curved panels that form the roof structure.

- Door Frames:

Precisely stamped frames ensuring proper fit for trailer doors.

4.2.3 Reinforcement and Accessory Components

- Reinforcement Bars:

Essential for structural stability.

- Mounting Brackets:

For attaching lights, hitches, and other accessories.

- Tie-Down Bars:

Reinforced bars to secure cargo.

- Storage Compartments:

Custom-formed panels for on-board storage.

- Protective Trim:

Decorative yet functional stamped trim elements.

4.3 Automotive-Related Products

The automotive industry utilizes metal stamping to produce components that balance performance with visual appeal.

4.3.1 Body Panels and Exterior Components

- Hoods:

Stamped components forming the engine cover.

- Doors:

Precisely formed panels ensuring proper alignment and aesthetics.

- Fenders:

Stamped to protect wheel wells and enhance aerodynamics.

- Roof Panels:

Curved panels that contribute to vehicle integrity.

- Trunk Lids:

Stamped parts designed for durability and appearance.

4.3.2 Chassis and Structural Components

- Subframes:

Critical stamped structures supporting the engine and suspension.

- Crossmembers:

Reinforcing elements for improved chassis rigidity.

- Side Rails:

Longitudinal components forming the vehicle's frame.

- Bumper Reinforcements:

Internally stamped parts enhancing impact resistance.

- Roll Cages:

Stamped structures for safety in performance vehicles.

4.3.3 Exhaust and Engine Components

- Exhaust Manifolds:

Precisely stamped to direct exhaust gases.

- Heat Shields:

Protective panels to guard against high temperatures.

- Engine Covers:

Stamped enclosures that protect engine components.

- Catalytic Converter Housings:

Structurally stamped for emission control.

- Air Intake Ducts:

Optimized stamped ducts for improved airflow.

4.3.4 Interior Components

- Dashboard Frames:

Stamped to provide a strong base for instrument clusters.

- Door Sills:

Reinforced panels offering durability and style.

- Center Consoles:

Stamped parts that integrate with vehicle interiors.

- Seat Frames:

Structural elements providing support and safety.

- Armrest Supports:

Precision-formed components for comfort and aesthetics.

4.3.5 Trim and Aesthetic Components

- Grille Frames:

Stamped for a refined front-end appearance.

- Window Frames:

Precision-formed to ensure proper sealing.

- Side Skirts:

Decorative panels enhancing the vehicle's profile.

- Mirror Housings:

Curved, stamped components for integrated mirrors.

- Roof Rails:

Functional and stylistic stamped elements.

4.4 Building Prefabrication-Related Products

Metal stamping is extensively used in building prefabrication to produce components that are both structural and decorative.

4.4.1 Structural Elements

- Wall Panels:

Stamped panels that form exterior or interior walls.

- Roofing Sheets:

Durable stamped sheets for weather-resistant roofs.

- Flooring Supports:

Reinforced components forming the base of raised floors.

- Beams and Girders:

Stamped elements providing critical support.

- Column Covers:

Decorative covers enhancing the appearance of structural columns.

4.4.2 Decorative and Functional Facade Components

- Curtain Walls:

Large stamped panels forming modern building exteriors.

- Sunshades:

Precision-formed fins reducing solar heat gain.

- Cladding Systems:

Stamped panels that provide both protection and style.

- Accent Elements:

Custom-formed trim and moldings for design enhancements.

- Canopies:

Overhanging stamped components offering both function and flair.

4.4.3 Utility and Accessory Elements

- Ventilation Grilles:

Stamped panels ensuring proper airflow in buildings.

- Cable Trays:

Formed components for organized wiring systems.

- Staircase Components:

Curved stamped parts used in modern stair design.

- Handrail Supports:

Structural elements securing safety railings.

- Utility Boxes:

Pre-formed stamped enclosures for electrical installations.

4.5 Additional Product Categories

Metal stamping also caters to various other industries:

- Consumer Appliances:

Stamped sinks, washing machine drums, and refrigerator panels.

- Packaging Components:

Metal containers and housings for industrial packaging.

- Furniture Components:

Curved metal parts used in contemporary furniture.

- Electronic Device Casings:

Stamped enclosures for printers, scanners, and other devices.

- Industrial Equipment Housings:

Protective casings and control panels for machinery.

4.6 Summary of Product-Related Content

Metal stamping enables the production of a wide array of high-quality components for diverse applications. Whether in servers, trailers, automobiles, or building prefabrication, the precision and efficiency of metal stamping ensure that every product meets rigorous quality and performance standards.

5. Factors for Selecting a Metal Stamping OEM Factory

Choosing the right metal stamping OEM factory is crucial for achieving production efficiency, superior quality, and long-term success. This section outlines the comprehensive factors you must consider when selecting a stamping partner in China.

5.1 Importance of Selecting the Right Partner

A reliable stamping OEM partner can optimize your production processes, reduce waste, and ensure that products meet strict quality requirements. The right partner provides not only advanced technology and skilled labor but also exceptional after-sales support.

5.2 Production Capacity and Equipment Capabilities

5.2.1 Advanced Machinery

- Modern Stamping Presses:

The partner should operate state-of-the-art stamping presses equipped with advanced CNC controls. These machines ensure precision, high throughput, and consistent part quality.

- Robust Clamping Systems:

Efficient clamping mechanisms are essential to hold metal blanks securely during the stamping process.

- Real-Time Monitoring:

Integrated sensors and feedback systems allow for dynamic adjustments, ensuring optimal process parameters.

5.2.2 High Production Throughput

- Scalability:

The facility must be capable of handling both low-volume custom orders and large-scale production runs without compromising on quality.

- Efficiency:

High throughput and quick cycle times are vital for meeting tight deadlines and reducing production costs.

5.3 Technical Expertise and Process Management

5.3.1 Skilled Workforce

- Experienced Engineers and Operators:

The partner should have a proven track record in metal stamping, supported by a team of experts who can fine-tune processes and troubleshoot issues effectively.

- Process Optimization:

Utilization of simulation tools and real-time process monitoring helps in refining the stamping process to minimize defects such as wrinkling and springback.

- Standard Operating Procedures:

Rigorous SOPs ensure consistent performance and quality across production runs.

5.4 Quality Control and Inspection Procedures

5.4.1 In-Process Quality Control

- Continuous Monitoring:

Quality control should begin at the raw material stage and continue through each production phase using tools like laser micrometers and CMM.

- Non-Destructive Testing:

Techniques such as CT scanning help verify internal dimensions and detect hidden defects.

5.4.2 Final Product Verification

- Comprehensive Inspection:

Final products should be inspected rigorously to ensure they meet all design specifications.

- Certifications:

International quality certifications (e.g., ISO 9001) are strong indicators of the partner's commitment to maintaining high standards.

5.5 Material Handling and Integrated Finishing

5.5.1 Material Expertise

- Diverse Material Experience:

The partner must have extensive experience with various metals such as aluminum, stainless steel, brass, copper, and mild steel.

- Quality Assurance of Materials:

Rigorous inspection and testing ensure that raw materials are consistent and of high quality.

5.5.2 In-House Finishing Capabilities

- Integrated Surface Treatments:

Capabilities such as polishing, anodizing, and powder coating streamline production and enhance product aesthetics.

- Efficiency:

In-house finishing minimizes handling time and reduces overall production lead times.

5.6 Turnaround Time and Flexibility

5.6.1 Fast Production Cycles

- Rapid Turnaround:

The partner should be capable of delivering products within short lead times while maintaining quality.

- Adaptability:

Flexibility in handling design changes and custom orders is essential in a competitive market.

5.6.2 Scalability and Lean Practices

- Efficient Workflow:

Lean manufacturing practices and efficient workflow management ensure that production scales without loss of quality.

- Responsive Operations:

The partner must be able to adjust production volumes based on demand fluctuations.

5.7 Cost Efficiency and Transparent Pricing

5.7.1 Clear Pricing Structure

- Transparency:

The pricing should be upfront and without hidden costs. A clear cost structure reflects the partner's advanced technology and quality control measures.

- Value for Money:

Evaluate overall value by considering potential savings from reduced material waste and increased production efficiency.

5.7.2 After-Sales Support

- Dedicated Support:

If quality issues or shipment discrepancies occur, the partner's after-sales service should manage returns, exchanges, or replenishments promptly and efficiently.

- Reliability:

Consistent after-sales support contributes to long-term partnership success.

5.8 Communication and Customer Service

5.8.1 Effective Communication

- Regular Updates:

The partner should provide timely updates on production status and any process adjustments.

- Responsive Service:

A dedicated customer service team that responds quickly to inquiries and resolves issues is crucial.

5.8.2 Collaborative Approach

- Tailored Solutions:

The ability to work collaboratively with your team and customize solutions to meet specific requirements is a significant advantage.

- Ongoing Feedback:

Open communication channels foster continuous improvement and innovation.

5.9 Certifications, Compliance, and Sustainability

5.9.1 Regulatory Adherence

- Industry Standards:

The partner must adhere to all relevant industry standards and environmental regulations.

- Sustainability Practices:

Commitment to sustainable manufacturing practices, including waste reduction and energy efficiency, is increasingly important.

5.9.2 Quality Certifications

- International Certifications:

Certifications such as ISO 9001 serve as benchmarks for quality and continuous improvement.

- Audit Results:

Regular audits and quality reviews provide additional assurance of the partner's reliability.

5.10 Long-Term Partnership and Innovation

5.10.1 Future Collaboration

- Research and Development:

A partner that invests in R&D and continuously improves its processes is better suited for long-term collaboration.

- Process Innovation:

Ongoing process improvements lead to higher product quality and lower production costs over time.

5.10.2 Trust and Reliability

- Reputation:

A strong industry reputation and proven track record are key indicators of a reliable partner.

- Mutual Growth:

Long-term partnerships enable mutual growth, fostering innovation and continuous improvement.

5.11 Summary of Partner Selection Factors

Selecting the right metal stamping OEM factory involves evaluating multiple factors—production capacity, technical expertise, quality control, material handling, turnaround time, cost efficiency, communication, certifications, and long-term innovation. A well-chosen partner not only meets immediate production needs but also supports ongoing improvements, ensuring that your manufacturing process remains competitive and efficient.

6. Conclusion

Choosing the right metal stamping OEM factory, especially when targeting "Metal Stamping Factories In China," is a decision that significantly influences your production efficiency, product quality, and overall competitiveness. This comprehensive guide has examined the critical factors in depth:

- We began by defining metal stamping and its importance, and we highlighted the benefits of partnering with a capable OEM in China.

- We then delved into production-related knowledge—covering mold design, process flows, advanced CNC integration, and common challenges with corresponding solutions.

- Material-related considerations were thoroughly discussed, emphasizing the properties, selection criteria, and finishing techniques required to achieve optimal results.

- A detailed review of product applications was provided, listing key examples for server, trailer, automotive, and building prefabrication products.

- Finally, we outlined essential partner selection factors, focusing on production capacity, technical expertise, quality control, material handling, turnaround time, cost efficiency, communication, certifications, and long-term collaboration.

By leveraging advanced production technologies, stringent quality control, and a skilled workforce, the ideal metal stamping OEM factory can help you optimize your operations and achieve consistent, high-quality output. Companies like HULK Metal exemplify these capabilities by offering precise sheet metal stamping services and dedicated after-sales support for quality issues and shipment discrepancies.

As you evaluate potential partners, use the criteria discussed in this guide to ensure that the factory you select aligns with your specific needs. A well-informed decision will not only streamline your production processes but also provide a competitive edge in the global marketplace.

Article Navigation

Article Navigation

Industries

Forging Factory

-

212024.11HULK Metal Stamping Factory Show

212024.11HULK Metal Stamping Factory Show -

182024.10HULK Metal Fabrication

182024.10HULK Metal Fabrication -

242025.03Metal Deep Drawing: A Comprehensive Guide

242025.03Metal Deep Drawing: A Comprehensive Guide -

212025.03Comprehensive Guide to Sheet Metal Bending

212025.03Comprehensive Guide to Sheet Metal Bending -

212025.03Sheet Metal Spinning

212025.03Sheet Metal Spinning -

242024.09The Most Comprehensive Introduction To Metal Stamping Dies

242024.09The Most Comprehensive Introduction To Metal Stamping Dies -

192024.09Introduction to Metal Stamping Processes

192024.09Introduction to Metal Stamping Processes