HULK Metal's Metal Laser Cutting Service converts your detailed sheet metal drawings into flawlessly cut components. Our expert team ensures precision, rapid production, and comprehensive support from design consultation to after-sales service.

Precision • Efficiency • Excellence

HULK Metal Metal Laser Cutting Service – Transforming Designs into Precision-Cut Masterpieces

-

Capacities

-

Processes

-

Parts

-

Factories

-

Moments

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

Metal Laser Cutting Service Capacities

Our Metal Laser Cutting Service handles diverse materials with tight tolerances and exceptional surface finishes. We offer precise cutting solutions for intricate designs, ensuring optimal dimensional accuracy and providing additional finishing and assembly support as needed.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

PROCESS: | Sheet Metal Laser Cutting |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / |

CERTIFICATION: | ISO 9001 |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Metal Laser Cutting Service

Our process begins with an in-depth consultation and design review, followed by customized solution development, meticulous sample testing, precise laser cutting, thorough quality inspections, secure packaging, and reliable after-sales service.

-

01

Understanding Your Idea

We start by gathering your drawings, production quantities, and specific requirements. Our team carefully reviews every detail to fully understand your design intent and ensure accurate translation into production.

-

02

Developing the Solution

Our engineers develop a tailored production plan outlining deadlines, process flow, and quality control measures. This solution specifies the optimal laser cutting technique and integrates robust inspection protocols for flawless results.

-

03

Sample Trial Production and Testing

We produce a sample batch to validate our approach. Rigorous testing of prototypes evaluates dimensional accuracy, cut quality, and material performance, ensuring all specifications are met before full-scale production begins.

-

04

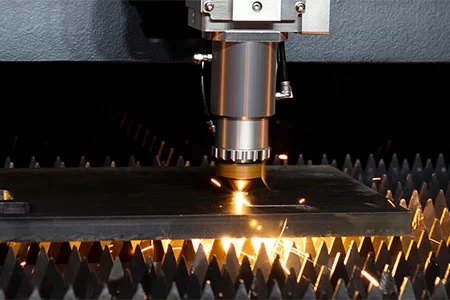

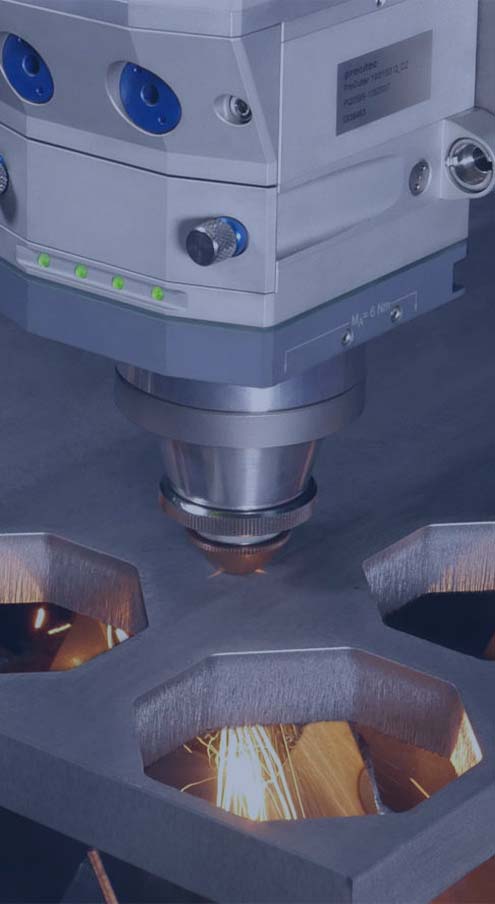

Laser Cutting

Utilizing advanced laser systems, our process delivers high-speed, precision cuts with minimal thermal distortion. The technology enables intricate patterns and complex designs while maintaining consistent quality across all components.

-

05

Quality Control Process Formulation

Our quality team establishes strict inspection protocols, incorporating ultrasonic and visual checks. Detailed procedures are set to monitor every production phase, ensuring each cut component adheres to our high-quality standards.

-

06

Production Scheduling

We coordinate production schedules meticulously, aligning workflow and resources to meet deadlines. Our planning process guarantees smooth transitions between stages, ensuring timely delivery of your laser-cut components.

-

07

Raw Material Procurement

Our procurement team sources premium metal sheets from trusted suppliers. We verify material certifications and quality to ensure that every batch meets the exacting standards required for precision laser cutting.

-

08

Quality Control

After cutting, components undergo thorough quality inspections. Our team uses state-of-the-art measuring tools to verify dimensions, ensuring each piece meets strict tolerances and maintains impeccable edge quality.

-

09

Surface Treatment

Post-cut, components may receive surface treatment to enhance finish and durability. We apply specialized coatings and treatments that improve corrosion resistance and provide a superior aesthetic appearance.

-

10

Packaging

Products are securely packaged using high-quality materials to protect them during transit. Our packaging process ensures that each laser-cut component remains undamaged and retains its precision finish until delivery.

-

11

Pre-shipment Inspection

A final inspection is conducted before shipment. Every component is re-verified for dimensional accuracy, surface quality, and overall integrity to ensure your order meets our rigorous standards.

-

12

Order Delivery

Following approval, your order is dispatched through our reliable logistics network. We ensure timely and secure delivery, providing updates throughout the shipping process for complete transparency.

-

13

After-sales Service

Our commitment continues after delivery. Should any quality issues arise, we offer prompt after-sales support including returns, exchanges, or replenishment services to guarantee complete customer satisfaction.

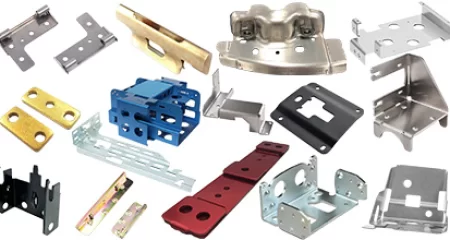

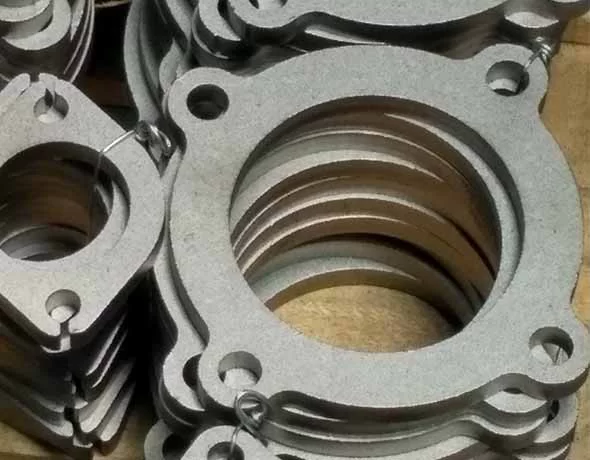

Metal Laser Cutting Parts We Have Produced

We have produced a diverse range of laser-cut parts including precision enclosures, intricate brackets, and custom panels. Each product demonstrates our ability to achieve high accuracy, clean edges, and exceptional surface finishes.

-

Custom OEM Server Rack Blank Panels

Custom OEM Server Rack Blank PanelsCustom OEM Server Rack Blank Panels—designed for precision, aesthetics, and tailored functionality. Engineered to seamlessly fill your server rack spaces, our panels offer robust protection and a refined finish.

READ MORE

-

Wall Mount Network Racks

Wall Mount Network RacksOur Wall Mount Network Racks are engineered to maximize space efficiency and secure your critical IT equipment. Customizable to your unique design, these solutions offer robust protection, optimal cooling, and streamlined cable management.

READ MORE

-

Network Server Rack Cable Management

Network Server Rack Cable ManagementWe Supports full customization of style, length, width, depth, etc. Smoother, cable protection, more durable of Network Server Rack Cable Management.

READ MORE

-

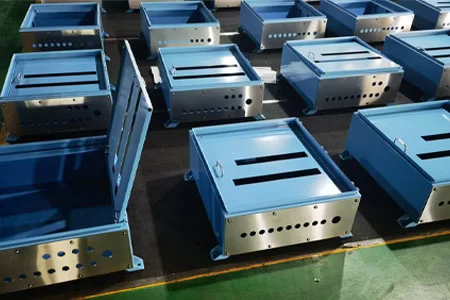

Laser Cutting Metal Parts Factory

Laser Cutting Metal Parts FactoryWe can develop a complete solution based on your server switch rack enclosure cabinets drawings, quantity, delivery time, transportation method and other requirements, allowing you to complete higher quality procurement tasks more easily.

READ MORE

-

Stone Fixing Brackets Factory In China

Stone Fixing Brackets Factory In ChinaHULK Metal strictly implements ISO 9001 quality management to provide higher quality stone fixing brackets. Our factory has advanced laser cutting machines, bending machines, punching machines, which can complete orders faster.

READ MORE

-

Aluminum Stamping Parts Factory In China

Aluminum Stamping Parts Factory In ChinaHULK Metal is a well-known sheet metal parts manufacturer in China, which provides complete solutions to produce higher quality customized sheet metal parts at lower prices.

READ MORE

-

China OEM Metal Stamping Parts

China OEM Metal Stamping PartsWe have abundant stamping factory resources and a complete supply chain to provide high-quality metal stamping parts OEM services. We have accumulated rich experience in OEM for hundreds of customers around the world and thousands of products.

READ MORE

-

Roof Rack Connectors Factory In China

Roof Rack Connectors Factory In ChinaWe focus on providing customers with high-quality metal fabrication services. To this end, we have integrated high-quality factory resources and established a complete supply chain.

READ MORE

-

Metal Beams Brackets

Metal Beams BracketsHULK Metal can provide high-quality metal beams brackets because our sheet metal factory has advanced cutting machines, stamping, and welding equipment, experienced workers, and QC center.

READ MORE

-

Metal Base Plate

Metal Base PlateHULK Metal has an ISO 9001-certified factory. We can develop complete production and quality inspection plans to provide high-quality metal base plate OEM services according to your requirements.

READ MORE

More Results

HULK Metal Sheet Metal Factory

Our modern sheet metal factory features advanced production lines, skilled technicians, and rigorous quality control. We offer comprehensive capabilities in stamping, laser cutting, assembly, surface treatment, and inspection to deliver exceptional metal fabrication.

Quality Control Center

Laser Cutting Workshop

Surface Treatment Workshop

Stamping Workshop

-

Quality Control Center

Our Quality Control Center is the backbone of our production process, equipped with state-of-the-art instruments and comprehensive testing protocols. Every component undergoes detailed inspections, including dimensional, surface, and structural assessments, at each production stage. Our experienced inspectors use ultrasonic testing, magnetic particle inspections, and statistical sampling to ensure all products meet stringent industry standards. Continuous monitoring and data-driven analysis allow for immediate corrective actions when necessary. Regular audits and meticulous documentation further reinforce our commitment to quality. This center guarantees a high delivery pass rate and uncompromised performance, ensuring that every product leaving our facility upholds the excellence expected from HULK Metal.

-

Laser Cutting Workshop

Equipped with cutting-edge laser systems, our laser cutting workshop delivers high-speed, precision cuts on a wide range of metal materials. Advanced automation and expert operators ensure clean, accurate edges with minimal distortion. The facility employs real-time monitoring and rigorous quality checks to verify dimensional accuracy and surface finish. This workshop's versatile equipment can handle intricate patterns and complex designs, supporting diverse project requirements. Routine maintenance and system calibrations guarantee peak performance. With a focus on efficiency and precision, our laser cutting workshop consistently meets tight tolerances and high-quality benchmarks, contributing significantly to our reputation for innovative metal fabrication.

-

Surface Treatment Workshop

In our surface treatment workshop, advanced finishing technologies ensure every component achieves a flawless appearance and enhanced durability. Automated powder coating lines and precision curing ovens apply uniform coatings with strict thickness control. Skilled technicians supervise the entire process, from surface preparation to final curing, ensuring optimal adhesion and resistance to wear. Rigorous quality inspections and environmental protection measures are in place to maintain high standards. This workshop delivers superior finishes that enhance both aesthetics and functionality. Continuous innovations and process improvements drive our commitment to sustainability and quality, making our surface treatment workshop a vital part of our comprehensive metal fabrication process.

-

Stamping Workshop

Our stamping workshop houses an extensive array of high-capacity presses that form precise blanks for various metal components. With advanced automation and large-scale equipment, the facility ensures rapid cycle times and accurate stamping operations. Skilled operators monitor every process, adhering to strict quality standards and performing real-time inspections. The workshop is designed to handle both small-batch prototypes and high-volume orders with consistency. Integrated quality control and continuous process improvements ensure minimal waste and optimal performance. This dynamic environment supports flexible production demands, making it a critical component of our overall metal fabrication capabilities.

Metal Laser Cutting Service Moments

Experience key moments in our laser cutting process—from precise cutting execution and accurate dimension measurements to flatness assessments, ultrasonic inspections, and final pre-shipment checks—ensuring every component meets our high standards.

-

Dimension Measurement

State-of-the-art digital systems verify precise dimensions, guaranteeing every cut meets exacting specifications.

-

Flatness Measurement

High-precision flatness tools ensure uniform surface alignment for a flawless, distortion-free finish.

-

Laser Cutting

Advanced laser cutting delivers precise, rapid cuts with minimal thermal distortion and exceptional edge quality.

-

Pre-shipment Inspection

A final comprehensive inspection confirms that all products meet our rigorous quality standards before delivery.

Benefits of Choosing HULK Metal's Metal Laser Cutting Service

Choosing HULK Metal for metal laser cutting offers access to advanced technology, expert craftsmanship, and comprehensive support. Our solutions ensure precision, speed, and quality, backed by stringent quality control and dedicated after-sales service.

-

Factory:

At HULK Metal, our factory features state-of-the-art laser cutting systems and automated production lines designed for high efficiency and precision. Our expansive facility, managed by skilled professionals, supports a wide range of metal fabrication needs, from intricate custom designs to high-volume production. Continuous investment in advanced equipment and process optimization ensures rapid turnaround times and consistent quality. This robust infrastructure enables us to meet demanding specifications while maintaining exceptional performance, positioning us as a leader in innovative metal processing.

-

Experience:

With over 20 years of industry expertise, HULK Metal has become synonymous with excellence in metal laser cutting. Our experienced team has served diverse industries, consistently delivering customized solutions that meet rigorous standards. Our deep technical knowledge, innovative approach, and commitment to continuous improvement allow us to tackle complex projects with efficiency and precision. Our proven track record of success and dedication to customer satisfaction ensures that every project is executed to perfection, building lasting partnerships with clients worldwide.

-

Quality:

Quality is the cornerstone of our metal laser cutting service. We strictly adhere to ISO 9001 standards and implement comprehensive quality control measures at every stage. Advanced inspection techniques—including digital measurement, ultrasonic testing, and visual inspections—ensure that each component meets stringent tolerances and superior surface finish criteria. Our dedicated quality control team performs regular audits and continuous monitoring to maintain the highest standards of excellence. This rigorous approach guarantees that every product not only meets but exceeds industry benchmarks, ensuring long-lasting performance and customer satisfaction.

-

Service:

HULK Metal is committed to providing end-to-end service that exceeds customer expectations. From initial consultation and detailed design review to production and reliable after-sales support, our team is dedicated to ensuring a seamless experience. Our well-integrated supply chain and logistics network enable timely delivery and efficient project management. Personalized customer service, proactive problem-solving, and responsive communication ensure that your needs are met at every stage. With our commitment to excellence and continuous support, HULK Metal stands ready to be your trusted partner in advanced metal laser cutting solutions.

Metal Laser Cutting Introduction

Discover HULK Metal's Metal Laser Cutting Service, where cutting-edge technology and expert craftsmanship converge to produce precision-cut metal components, backed by rigorous quality control and exceptional after-sales support.

-

Metal Laser Cutting Means:

Our metal laser cutting means employing state-of-the-art laser technology to achieve ultra-precise cuts on a variety of metal materials. The process utilizes high-powered, finely focused laser beams that produce clean, sharp edges with minimal thermal impact. Automated systems and sophisticated control software ensure that every cut meets exacting tolerances and intricate design requirements. Skilled technicians oversee operations to adapt cutting parameters for different materials and thicknesses, optimizing performance and minimizing waste. This advanced method not only enhances production speed but also significantly improves product quality, making it a critical component of our comprehensive metal fabrication solutions.

-

Metal Laser Cutting Application:

Metal laser cutting at HULK Metal is widely applied across industries such as automotive, aerospace, electronics, and construction. Our precise cutting technology is ideal for creating complex components, custom prototypes, and large-scale production parts with intricate designs. The process can handle a variety of metal types and thicknesses, ensuring versatility and high precision. It enables the production of detailed patterns and consistent finishes that reduce the need for secondary processing. Our expertise ensures that every project, from small batch runs to high-volume orders, is executed with maximum efficiency and superior quality, driving performance and innovation in your final products.

Choose HULK Metal As Your Partner:

Choosing HULK Metal as your partner means working with a leader in advanced metal laser cutting solutions. We combine decades of industry experience with state-of-the-art technology to transform your design concepts into precise, high-quality components. Our collaborative approach ensures that every project is tailored to your specific needs, from initial consultation and solution development to production and after-sales service. With robust quality control measures and a commitment to excellence, we deliver results that consistently exceed expectations. Partner with us to benefit from innovative technology, dedicated support, and efficient production processes that drive success in even the most demanding applications.

Feel free to contact us for a personalized quote and discover how HULK Metal's Metal Laser Cutting Service can transform your designs into precision-engineered, high-quality components.

Articles Related to Metal Laser Cutting

Explore our curated articles on metal laser cutting, featuring the latest industry trends, technological advancements, and expert tips. Gain insights to optimize your metal fabrication projects with precision, efficiency, and innovation.

-

November 21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October 18, 2024

HULK Metal Fabrication

READ MORE

-

October 25, 2024

Comprehensive Guide to Sheet Metal Cutting: Methods, Materials, and Choosing the Right Partner

READ MORE

-

September 27, 2024

8 Types of Sheet Metal Assembly Technology and Their Processes and Applications

READ MORE

-

September 19, 2024

Introduction to Metal Stamping Processes

READ MORE