HULK Metal delivers comprehensive sheet metal forming services by transforming client drawings into precision‐engineered parts. Our expert team combines innovative design, state‐of‐the‐art production, and dedicated after-sales support, ensuring high‐quali

Innovative Engineering Solutions

HULK Metal Sheet Metal Forming Services – Precision, Performance, and Reliability

-

Capacities

-

Processes

-

Parts

-

Factories

-

Moments

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

Sheet Metal Forming Services Capacities

Our sheet metal forming capacities encompass a wide range of techniques including bending, stamping, and deep drawing. We work with diverse materials, maintain strict tolerances, offer various surface treatments, and provide custom finishing solutions alongside precision assembly services, ensuring excellence.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

PROCESS: | Forming |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Sheet Metal Forming Service

Our comprehensive sheet metal forming process begins with detailed consultation and design review, followed by mold creation, trial production, and quality testing. We then execute full‐scale production, assembly, packaging, final inspection, delivery, and provide dedicated after-sales support with unmatched precision.

-

01

Understanding Your Idea

We begin by thoroughly understanding your project vision. Our team collects detailed drawings, quantity requirements, and specific client needs to ensure that every aspect of your design is comprehensively reviewed for optimal planning and execution.

-

02

Developing the Solution

Our engineers craft a tailored solution by analyzing the project scope. We establish a precise production timeline, select the optimal forming process, schedule all production phases, and develop a comprehensive quality control strategy alongside additional service measures.

-

03

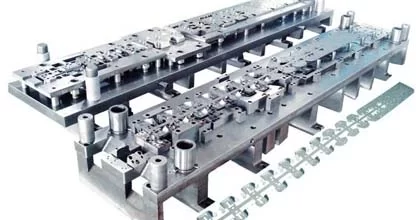

Mold Manufacturing

Based on your project requirements, we determine the most suitable mold type and material. Our expert technicians then design and manufacture high-precision molds, ensuring they meet rigorous standards for durability and performance throughout the production cycle.

-

04

Sample Trial Production and Testing

We initiate a sample trial production to validate design and process accuracy. This stage includes rigorous testing of prototypes, ensuring dimensional accuracy and functional performance, while identifying any adjustments needed for optimal mass production efficiency.

-

05

Quality Control Process Formulation

Our quality control team develops and implements strict quality control processes. We define detailed inspection protocols, sampling methods, and testing procedures to ensure that every component adheres to industry standards and our high-performance benchmarks.

-

06

Production Scheduling

We meticulously schedule production to optimize workflow and resource allocation. By coordinating with all departments, we ensure timely completion of each stage, maintaining seamless transitions from design to manufacturing while adhering to strict deadlines.

-

07

Raw Material Procurement

Our procurement team sources high-quality raw materials from reliable suppliers. We rigorously assess material specifications, ensuring that each input meets precise quality standards essential for consistent performance throughout the forming process.

-

08

Sheet Metal Blanking

In the blanking phase, raw materials are precisely cut to predetermined dimensions. This step is executed with high precision to eliminate waste, maintain consistency, and prepare the materials for the subsequent forming operations effectively.

-

09

Forming

During the forming stage, advanced machinery shapes the blanked materials into intricate components. Our process employs precision techniques to achieve exact dimensions, smooth surfaces, and consistent quality, ensuring each part meets your specific design requirements.

-

10

Assembly

Post-forming, components are assembled using methods such as welding and riveting. Our skilled technicians carefully integrate individual parts, ensuring robust structural integrity and precise alignment, which are critical for the overall functionality and longevity of the final product.

-

11

Packaging

Once assembly is complete, each product is meticulously packaged to prevent damage during transit. We use secure and efficient packaging methods that protect the integrity of the components while facilitating easy handling and shipment.

-

12

Pre-shipment Inspection

Before shipment, our quality team conducts a thorough pre-delivery inspection. Every product undergoes detailed measurements, surface checks, and functionality tests to confirm that all specifications are met, ensuring a defect-free final product.

-

13

Order Delivery

After successful final inspections, products are carefully loaded and delivered to our customers. We coordinate logistics to ensure timely and safe transportation, keeping you informed throughout the process for a seamless delivery experience.

-

14

After-sales Service

Our commitment continues even after delivery. If any quality issues arise, we promptly offer after-sales support, including returns, exchanges, or replenishment services. We ensure customer satisfaction with responsive, professional assistance every step of the way.

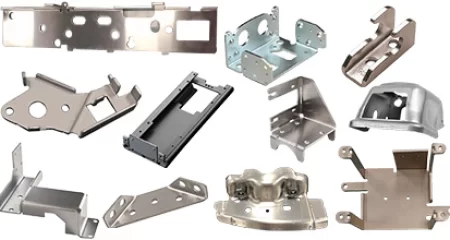

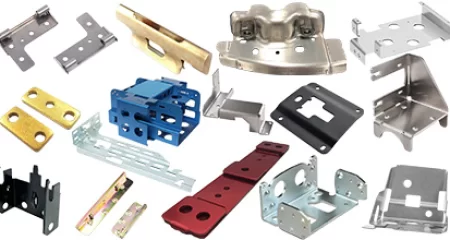

Sheet Metal Forming Parts We Have Produced

We have produced a diverse array of sheet metal forming parts ranging from intricate enclosures and structural components to custom brackets and precision fittings. Each product reflects our commitment to quality, innovative design, and adherence to strict dimensional tolerances, excellently.

-

Custom Wall Mount Network Rack

Custom Wall Mount Network RackPartner with HULK Metal for exceptional contract manufacturing of Wall Mount Network Racks. Benefit from our precision engineering, streamlined processes, and rigorous quality control—delivering robust, custom-designed racks that enhance your network infrastructure.

READ MORE

-

Heavy Duty Network Server Cable Management

Heavy Duty Network Server Cable ManagementPartner with HULK Metal for unmatched contract manufacturing of Heavy Duty Network Server Cable Management systems. Enjoy precision engineering and superior quality that enhances your network's reliability and efficiency. Experience cost-effective, tailor-made solutions to meet your unique requirements today.

READ MORE

-

Stainless Steel Stamping Parts Factory In China

Stainless Steel Stamping Parts Factory In ChinaHULK Metal is one of the top OEM service providers in China with an ISO9001 certified stainless steel stamping parts factory. Contact us to get the latest discount prices.

READ MORE

-

China OEM Metal Stamping Parts

China OEM Metal Stamping PartsWe have abundant stamping factory resources and a complete supply chain to provide high-quality metal stamping parts OEM services. We have accumulated rich experience in OEM for hundreds of customers around the world and thousands of products.

READ MORE

-

Winch Post for Boat Trailer Factory in China

Winch Post for Boat Trailer Factory in ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

More Results

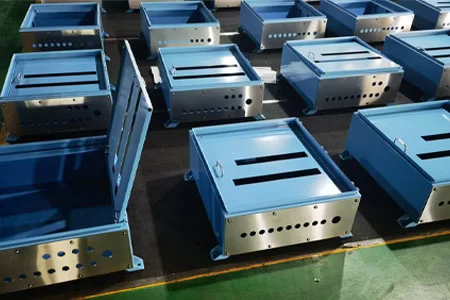

HULK Metal Sheet Metal Forming Factory

HULK Metal's Sheet Metal Forming Factory combines advanced machinery, skilled workforce, and rigorous quality control to deliver precision metal fabrication. Our modern facility optimizes production through automated processes, ensuring efficient, high-quality components that meet stringent industry standards and exceed expectations.

Laser Cutting Workshop

Forming Workshop

Riveting Workshop

Quality Control Center

Welding Workshop

Surface Treatment Workshop

-

Laser Cutting Workshop

Our Laser Cutting Workshop is equipped with state-of-the-art cutting systems that operate with high automation. Expert operators manage precision cutting, ensuring each part is accurately processed to exact specifications. The facility emphasizes strict quality inspections, guaranteeing optimal surface finishes and consistent dimensions. With a focus on efficiency and reliability, our laser cutting capabilities enable rapid turnaround on complex projects. This workshop's advanced technology, combined with skilled personnel and rigorous quality control protocols, ensures that every cut meets stringent industrial standards, making it a cornerstone of our comprehensive metal processing operations. Our commitment to innovation drives continuous improvement in performance remarkably.

-

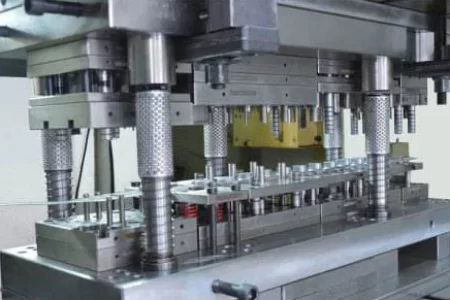

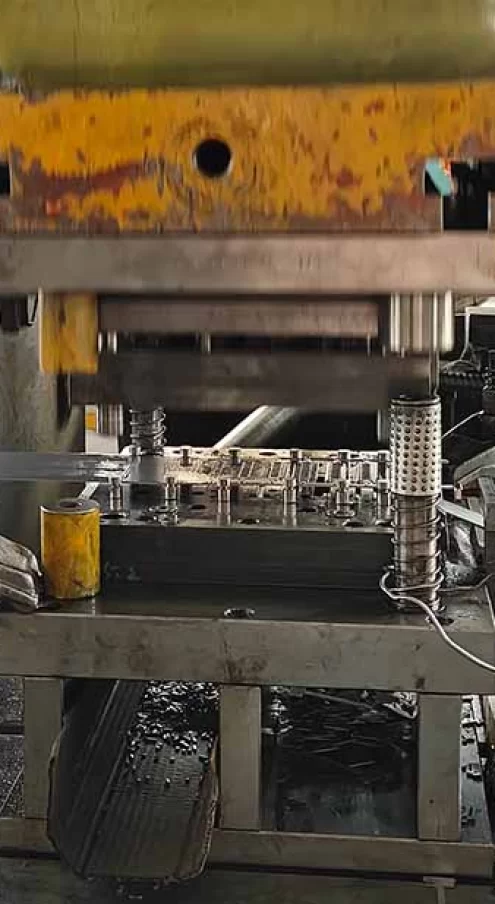

Forming Workshop

Our Sheet Metal Forming Workshop is a hub of precision engineering, featuring a high number of advanced forming machines that operate at a semi-automated level. The facility boasts spacious production areas where experienced technicians expertly handle complex operations. Emphasizing stringent quality inspections, our workshop ensures every component meets industry standards. Additionally, our robust stamping capabilities allow for efficient processing of high-volume orders without compromising accuracy. This blend of modern machinery, skilled workforce, and rigorous quality control makes our forming workshop a leader in reliable metal fabrication. Our ongoing innovations and rigorous training programs further enhance our production speed and quality.

-

Riveting Workshop

Our Riveting Workshop utilizes diverse riveting methods to secure metal components reliably. The facility is outfitted with advanced riveting equipment that enhances automation and precision. Highly trained operators perform every riveting task with consistent accuracy, while stringent quality inspections guarantee uniformity and structural integrity. Emphasizing speed and efficiency, our riveting operations integrate modern technology with hands-on expertise, ensuring durable connections in every assembly. This systematic approach not only optimizes production but also minimizes errors, reinforcing our commitment to superior quality and performance in every project we undertake. Our continuous innovation and rigorous training further boost productivity and overall riveting excellence consistently.

-

Quality Control Center

Our Quality Control Center utilizes cutting-edge instruments and systematic testing procedures to verify product integrity at every stage. Detailed inspection protocols, including dimensional analysis and surface evaluation, ensure that all items meet our rigorous standards. Skilled inspectors conduct regular audits and provide comprehensive reports on quality metrics. With continuous monitoring and adherence to strict sampling guidelines, our center guarantees a high delivery pass rate. This meticulous approach, combined with ongoing training and process improvements, reinforces our commitment to excellence and consistency in metal fabrication, ensuring every product exceeds customer expectations. Our dedicated inspectors and advanced systems consistently deliver unparalleled quality with precision.

-

Welding Workshop

Our Welding Workshop features a variety of welding techniques including MIG, TIG, and spot welding, ensuring robust joins for diverse applications. Equipped with modern automated welding equipment, the facility supports high precision and repeatable quality. Skilled welders with extensive industry experience meticulously execute every joint, supported by stringent quality inspections. The workshop also integrates efficient cutting systems for complementary operations. By focusing on advanced technology, operator expertise, and rigorous quality control, our welding operations consistently deliver durable, high-performance components that meet and exceed industrial standards. Continuous process optimization and ongoing training further elevate our welding excellence and product reliability significantly.

-

Surface Treatment Workshop

Our Surface Treatment Workshop features an advanced powder coating line designed to deliver superior surface quality and consistent thickness across all products. The facility is dedicated to rigorous quality inspections and environmental protection, ensuring that coatings meet stringent industry standards. With automated processes and skilled technicians, our operations achieve high durability and aesthetic appeal. Continuous process improvements, strict monitoring of coating parameters, and eco-friendly practices combine to produce flawless finishes. This commitment to excellence guarantees that every treated component not only looks exceptional but also performs reliably under diverse operational conditions. Our dedicated team ensures consistent, eco-conscious quality every time.

Sheet Metal Forming Moments:

Experience key moments in our sheet metal forming process, from precision mold creation and continuous production to dimension and flatness measurements, advanced ultrasonic testing and rigorous pre-shipment inspections. Each moment reflects our commitment to quality and efficiency in every project.

-

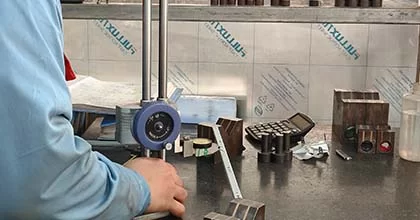

Dimension Measurement

Precise dimension measurement ensures each part adheres to exact specifications, reinforcing our commitment to quality.

-

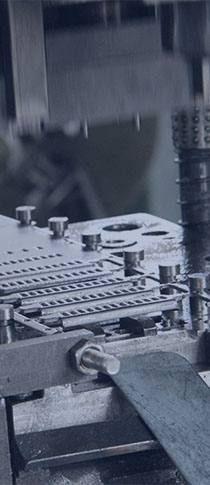

Continuous Mold Production

Our continuous mold production process streamlines manufacturing, ensuring consistent quality and efficiency in every run.

-

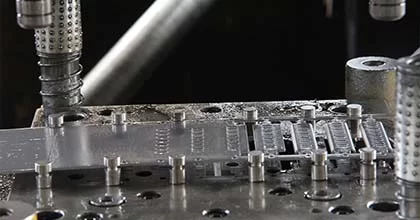

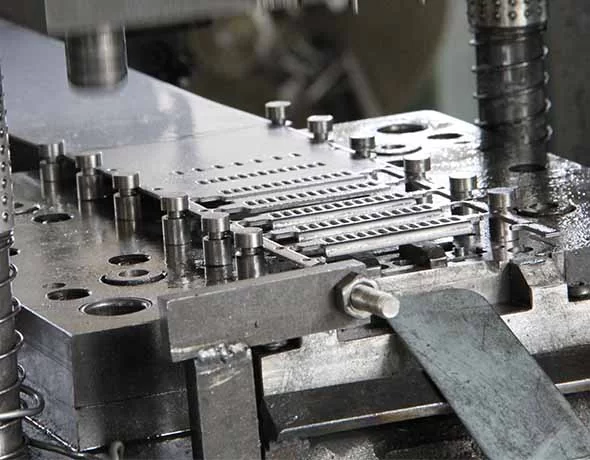

Forming Mold

Engineered forming molds demonstrate durability and precision, crafted to exact client specifications for optimal performance.

-

Flatness Measurement

Accurate flatness measurement validates surface uniformity, guaranteeing reliable performance and aesthetic appeal in every component.

-

Ultrasonic Testing

Advanced ultrasonic testing detects internal flaws, ensuring structural integrity and safety for all manufactured parts.

-

Pre-shipment Inspection

Final pre-shipment inspection confirms product excellence, verifying all dimensions, finishes, and functionality before dispatch thoroughly.

Benefits of Choosing HULK Metal's Sheet Metal Forming

Choosing HULK Metal for sheet metal forming offers unmatched advantages. Our state-of-the-art facilities, experienced professionals, and rigorous quality standards ensure reliable, precise, and efficient production. We provide full-cycle support from design to after-sales service, delivering customized solutions that consistently exceed industry expectations and drive customer success with proven global expertise.

-

Factory

At HULK Metal, our factory is a powerhouse of modern metal forming technology. Featuring production lines with high-capacity machinery and automated systems, we ensure efficient and precise fabrication. Our spacious facility is staffed by highly trained professionals dedicated to delivering superior performance. Continuous investments in advanced equipment and process optimization enable rapid scalability and consistent quality. This robust infrastructure positions us to meet diverse project demands and deliver exceptional results, reinforcing our reputation as a leader in metal processing innovation.

-

Experience

With over 20 years of industry experience, HULK Metal has mastered the art of sheet metal forming. Our seasoned professionals bring a wealth of technical expertise and innovative problem-solving skills to every project. Serving more than 20 industries, we consistently deliver custom solutions that meet unique design requirements. Our extensive portfolio reflects our ability to adapt to complex challenges and produce high-quality results under tight deadlines. This rich experience not only fuels our continuous improvement but also builds client relationships.

-

Quality

Our commitment to quality is unwavering. We adhere to ISO 9001 standards and perform rigorous inspections using advanced testing instruments at every production stage. Detailed quality audits, systematic process monitoring, and precise tolerance measurements ensure each component meets strict durability criteria. Our integrated quality control system, combined with continuous staff training, guarantees reliable, safe, and superior products. This meticulous focus on quality reinforces our reputation as an industry leader and drives customer satisfaction in all our metal forming projects, consistently.

-

Service

Our comprehensive service at HULK Metal goes beyond production. We offer end-to-end support from initial consultation and design optimization to timely delivery and dedicated after-sales care. Our responsive customer service team collaborates closely with clients to address all queries and provide expert guidance. With a well-established supply chain and efficient logistics, we ensure seamless order management and prompt resolution of any issues. This integrated service approach guarantees customer satisfaction and fosters long-term partnerships built on trust, reliability, and technical support.

Metal Forming Services Introduction

Our Metal Forming Services encompass a full range of solutions tailored to your design needs. We combine innovative technology with expert craftsmanship to deliver precise, durable components. Experience seamless production from concept to completion with our comprehensive service offerings today.

-

Metal Forming Service Means

Our metal forming service means providing a complete, end-to-end solution that covers every aspect of sheet metal fabrication. From initial consultation and precise design interpretation to advanced forming techniques and rigorous quality testing, we ensure each step meets stringent standards. Our state-of-the-art equipment and experienced workforce work in unison to produce components that adhere to exact specifications. We leverage innovative technology to optimize production efficiency while maintaining superior quality. Throughout the process, our dedicated team collaborates closely with clients, offering tailored solutions and timely support. This integrated approach guarantees reliability, consistency, and exceptional performance in every project we undertake seamlessly.

-

Metal Forming Service Application

Our metal forming services are applicable across a broad spectrum of industries, including automotive, aerospace, electronics, and consumer goods. We transform client concepts into reality by creating complex, custom components that meet strict industry standards. Our capabilities include bending, stamping, and deep drawing processes, tailored to both prototype and mass production requirements. Whether you need small-scale precision parts or large, high-volume assemblies, our solutions are designed to deliver unmatched accuracy and durability. We also offer post-production services to ensure continuous support and optimal product performance. Trust our expertise to handle your most demanding metal forming projects with professionalism and innovation.

Choose HULK Metal As Your Partner:

Choose HULK Metal as your trusted partner for sheet metal forming and fabrication services. Our proven expertise, cutting-edge technology, and commitment to quality ensure that your projects are executed with precision and efficiency. We work collaboratively with you from initial consultation to final delivery, offering customized solutions tailored to your unique requirements. With a robust production infrastructure and dedicated after-sales support, we guarantee reliable performance and timely results. Our industry experience and innovative approach make us the ideal choice for both small-scale prototypes and large, high-volume orders. Partner with us to experience superior craftsmanship and exceptional service in every project.

You can click the link below to enter the Contact Us page to leave a message and upload drawings to get a more satisfactory solution and quotation.

Article of Sheet Metal Forming

Explore our curated articles on metal forming services to discover insights into innovative fabrication techniques, quality control practices, and industry trends. Gain valuable knowledge and practical tips that highlight our commitment to excellence and drive continuous improvement in metal processing.

-

November 21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October 18, 2024

HULK Metal Fabrication

READ MORE

-

October 29, 2024

Introduction to Sheet Metal Forming: Processes, Materials, and Choosing the Right Partner

READ MORE

-

October 24, 2024

Comprehensive Guide to Sheet Metal Blanking

READ MORE

-

September 30, 2024

Comprehensive Understanding of Sheet Metal Welding

READ MORE

-

September 27, 2024

8 Types of Sheet Metal Assembly Technology and Their Processes and Applications

READ MORE

-

September 24, 2024

The Most Comprehensive Introduction To Metal Stamping Dies

READ MORE