HULK Metal is a Chinese factory that has been providing high-quality sheet metal punching services to global customers since 2000. We have integrated a complete supply chain to provide you with higher standards of production, packaging, transportation and

Sheet Metal Blanking Factory In China

Provide Excellent Sheet Metal Blanking Service

-

Capacities

-

Processes

-

Parts

-

Other Types

-

Factory

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

Sheet Metal Blanking Services Capacities

The breadth of our sheet metal blanking services capabilities is showcased in this table. It covers OEM methods, raw materials, blanking processes, tolerances, machining capabilities, surface treatment options, and more. For further details, please reach out to us. You can submit drawings, specify quantities needed, and indicate your preferred delivery method. This information will enable us to tailor comprehensive solutions and provide accurate quotations promptly.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

PROCESS: | Blanking |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / |

CERTIFICATION: | ISO 9001 |

TOLERANCE: | Ra:0.05µm |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process Of our Sheet Metal Blanking Service

At Hulk Metal, we are dedicated to delivering superior sheet metal blanking solutions with precision, efficiency, and reliability. Our comprehensive process ensures that your project requirements are met with the highest standards of quality and service

-

01

Consultation and Design Solution

The process begins with a thorough consultation where we discuss your project requirements and specifications. Our engineering team reviews your drawings to ensure they are optimized for manufacturability and cost-effectiveness.

-

02

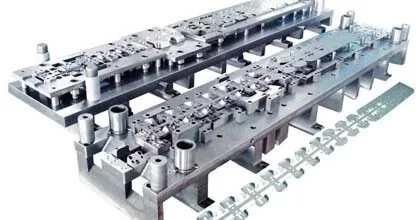

Molds Making Setup

Custom mold and fixtures are prepared or selected based on the specific geometries and dimensions of the blanks required.

-

03

Blanking Process

The sheet metal blanks are produced using advanced machines. Our processes ensure high-speed and accurate blanking to create the desired shapes and sizes.

-

04

Quality Control

Throughout the blanking process, rigorous quality checks are conducted to verify dimensional accuracy and adherence to tolerances.

-

05

Material Selection and Preparation

We assist in selecting the appropriate sheet metal material based on your application and performance requirements. Raw materials are inspected for quality and prepared for the blanking process.

-

06

Optional Secondary Operations

Depending on your requirements, optional secondary operations such as deburring, edge smoothing, or surface treatments can be performed.

-

07

Other Process

Metal Blanks will undergo other processes such as forming, heat treatment, etc. Blanked parts can also be used as final products in various industries.

-

08

Delivery and Customer Support

We coordinate delivery logistics to ensure the timely arrival of your sheet metal parts. Our customer support team is available to address any inquiries or concerns throughout the process and beyond.

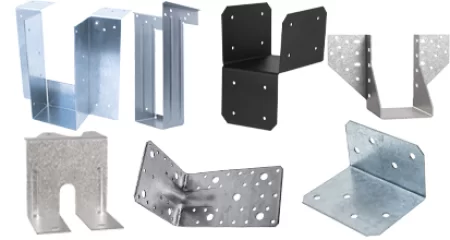

Parts Our Sheet Metal Blanking Service Produced

Each part produced through our sheet metal blanking service undergoes meticulous quality control to ensure precision, consistency, and adherence to industry standards. Whether you require standard components or specialized parts, Hulk Metal is committed to delivering high-quality solutions that meet your project needs effectively.

-

Trailer Tire Carrier Factory In China

Trailer Tire Carrier Factory In ChinaWhen choosing a trailer tire carrier OEM with excellent production capabilities, we usually look for companies that can provide higher quality products and services at a more favorable price.

READ MORE

-

Trailer Stake Pocket Manufacturer In China

Trailer Stake Pocket Manufacturer In ChinaHULK Metal is dedicated to providing excellent trailer stake pocket manufacturing services to numerous suppliers. We have an experienced technical team, an ISO 9001 and ISO 16949 certified sheet metal factory, and supporting logistics.

READ MORE

-

Roof Rack Connectors Factory In China

Roof Rack Connectors Factory In ChinaWe focus on providing customers with high-quality metal fabrication services. To this end, we have integrated high-quality factory resources and established a complete supply chain.

READ MORE

-

Wood Framing Connectors

Wood Framing ConnectorsOur sheet metal fabricating plant strictly implements ISO 9001 quality management and provides you with high-quality sheet metal cutting, stamping, welding, and surface treatment services.

READ MORE

-

Metal Beams Brackets

Metal Beams BracketsHULK Metal can provide high-quality metal beams brackets because our sheet metal factory has advanced cutting machines, stamping, and welding equipment, experienced workers, and QC center.

READ MORE

-

Angle Iron Connectors Construction Hardware

Angle Iron Connectors Construction HardwareWe can produce Angle Iron Connectors with thicknesses below 15mm. We can develop a more suitable solution based on your requirements and drawings.

READ MORE

More Results

HULK Metal Stamping Factory

The equipment at Hulk Metal allows us to offer comprehensive metal stamping and fabrication services, from initial cutting and stamping to welding, surface treatment, and rigorous quality control, all under one roof.

Cutting Factory

QC Center

Surface Treatment

Stamping Factory

Welding Factory

-

Cutting Factory

Located within our facility, the cutting factory is equipped with advanced CNC machines and laser cutting technology. This factory specializes in precision cutting of sheet metal to prepare blanks for further processing in our stamping and fabrication processes.

-

QC Center

At the heart of our operations, the QC Center is equipped with state-of-the-art inspection tools and methodologies to ensure every part meets stringent quality standards. Our dedicated quality control team conducts thorough inspections throughout the production process, from raw material inspection to final product verification, ensuring that all components leaving our facilities meet or exceed customer expectations and industry regulations.

-

Surface Treatment

In our surface treatment factory, we offer comprehensive finishing services to enhance the appearance, durability, and corrosion resistance of metal components. This includes processes such as powder coating, electroplating, anodizing, and other customized finishes tailored to meet specific customer requirements.

-

Stamping Factory

Our stamping factory houses a range of mechanical and hydraulic stamping presses capable of handling various sizes and complexities of parts. This facility is pivotal in producing stamped components with high efficiency and accuracy, ensuring consistent quality across production runs.

-

Welding Factory

The welding factory at Hulk Metal is dedicated to joining metal components using advanced welding techniques such as Laser welding and arc welding. our factory ensures robust and durable assemblies for a wide range of applications, including automotive, industrial machinery, and structural components.

Sheet Metal Blanking Moments

Here, you will find pictures showcasing key moments of our sheet metal blanking process, including our quality inspection center and various stages of production. Click to learn more or contact us directly. We can arrange a visit to our stamping factory, provide detailed introductions, and offer comprehensive solutions and quotations.

-

Blanking to Specific Size

Using precision blanking dies, metal sheets are punched to specific sizes, preparing them for subsequent manufacturing processes. This method ensures uniformity and efficiency in producing high volumes of identical blanks.

-

Punching Holes

Blanking dies are also used to punch holes in metal sheets efficiently. While this method is faster than cutting and drilling, it may not achieve the same level of accuracy as these more precise techniques.

-

Other Blanking Moments

To explore more about our stamping factory and see additional blanking moments in action, please click on the link below.

Start Sheet Metal Blanking Services

Welcome to Hulk Metal, where precision meets productivity in the realm of sheet metal fabrication. We are thrilled to announce the launch of our new sheet metal blanking services, designed to cater to the diverse needs of our clients over-world.

-

Factory:

Located in China, Hulk Metal operates from a cutting-edge manufacturing facility spanning 4000. Our factory is equipped with the latest in sheet metal blanking technology, featuring automated CNC machines and precision tools. This setup allows us to handle both high-volume production runs and intricate, customized orders with equal efficiency. Our commitment to investing in advanced machinery ensures that we deliver consistent, high-quality sheet metal blanks to our clients.

-

Experience:

With a legacy of 20 Years in the sheet metal fabrication industry, Hulk Metal has garnered a reputation for excellence and reliability. Our team comprises seasoned professionals, including skilled technicians and engineers who bring expertise in sheet metal blanking techniques. Whether it's simple shapes or complex geometries, we have the knowledge and capability to meet diverse customer requirements. Over the years, we have honed our processes to optimize efficiency and precision, ensuring that every blank produced meets stringent quality standards.

-

Quality:

Quality assurance is at the core of Hulk Metal's operations. We adhere strictly to ISO [Insert ISO Certification Number] standards and implement comprehensive quality control protocols throughout the blanking process. From material inspection and initial tool setup to final inspection and packaging, every step is meticulously monitored to guarantee that our sheet metal blanks not only meet but exceed industry specifications. Continuous improvement and feedback loops are integral to our quality management system, enabling us to deliver superior products consistently.

-

Service:

At Hulk Metal, we prioritize customer satisfaction by offering personalized service tailored to each client's unique needs. Our dedicated team works closely with customers from the initial consultation phase through to delivery, ensuring clear communication and responsiveness at every stage of the project. We understand the importance of timelines and reliability in our industry, which is why we emphasize efficient project management and logistics to ensure on-time delivery of finished sheet metal blanks. Whether you're a small business or a large-scale manufacturer, Hulk Metal is committed to providing a seamless experience and exceptional service.

Metal Blanking Services Introduction

Here, you can explore the definition of sheet metal blanking services, discover the industries that utilize these services to produce parts, and learn about the materials suitable for sheet metal part production. Additionally, find out the benefits of choosing HULK Metal for your sheet metal part manufacturing needs.

-

Metal Blanking Service Means

Metal blanking is a precision manufacturing process where flat sheet metal is cut into specific shapes, known as blanks. These blanks serve as raw material for further fabrication or assembly processes. The process typically involves using specialized tooling and machinery to achieve precise cuts according to customer specifications. At Hulk Metal, our metal blanking services are characterized by advanced technology, meticulous craftsmanship, and a commitment to quality.

-

Metal Blanking Service Application:

Metal blanking services find application across various industries and sectors, including:

Automotive: Producing components like brackets, panels, and structural parts.

Electronics: Creating enclosures, covers, and mounting plates for electronic devices.

Aerospace: Manufacturing precision parts for aircraft and spacecraft applications.

Appliances: Supplying parts for household appliances such as ovens, refrigerators, and washing machines.

Construction: Providing structural components and fittings for building and infrastructure projects.

Industrial Equipment: Manufacturing components for machinery, HVAC systems, and industrial tools.

Choose HULK Metal As Your Partner:

When you choose Hulk Metal for your metal blanking needs, you benefit from:

Advanced Technology: Our state-of-the-art machinery and CNC capabilities ensure high precision and efficiency in blank production.

Quality Assurance: Rigorous quality control measures guarantee that every blank meets stringent standards for accuracy and consistency.

Customization: We offer flexibility to accommodate custom designs, materials, and finishing options to suit diverse project requirements.

Reliability: With years of experience and a proven track record in the industry, we are committed to delivering on time and exceeding customer expectations.

You can click the link below to enter the Contact Us page to leave a message and upload drawings to get a more satisfactory solution and quotation.

Article of Sheet Metal Blanking

Below is a comprehensive introduction encompassing sheet metal stamping processes, materials, molds, applications, and more. Discover how partnering with a proficient sheet metal stamping service provider can optimize costs and enhance efficiency. For further details, feel free to contact us directly.