HULK Metal's Metal Laser Welding Service transforms your detailed designs into flawlessly welded components. Our expert team ensures high precision, exceptional durability, and comprehensive support from initial consultation through final delivery.

Precision • Innovation • Reliability

HULK Metal Metal Laser Welding Service – Engineering Excellence Unleashed

-

Capacities

-

Processes

-

Parts

-

Factories

-

Moments

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

Metal Laser Welding Service Capacities

Our Metal Laser Welding Service handles diverse materials with tight tolerances and superior surface finishes. We offer customizable welding solutions featuring precise seam control and integrated post-weld treatments to meet the most demanding industrial standards.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron Sheet / Steel Sheet / Stainless Steel Sheet / Aluminum Sheet |

PROCESS: | Sheet Metal Welding |

SURFACE TREATMENT: | Anodizing / Electrophoresis / Passivating / Galvanizing / Powder Coating / Polishing / |

CERTIFICATION: | ISO 9001 |

MACHINING: | Drilling / Tapping / Turning / Milling |

MOQ: | 300KG |

Process of Our Metal Laser Welding Service

Our process begins with a detailed consultation, followed by solution development, meticulous production scheduling, advanced laser welding execution, rigorous quality inspections, and ends with comprehensive after-sales support to ensure flawless results.

-

01

Understanding Your Idea

During our initial consultation, we carefully review your provided drawings, quantity requirements, and specific design details. This thorough discussion ensures we fully understand your vision and technical needs for optimal production planning.

-

02

Developing the Solution

Our engineering team crafts a tailored solution that outlines production timelines, selects the appropriate laser welding techniques, and establishes quality control measures. This comprehensive plan ensures timely delivery and meets your exact specifications.

-

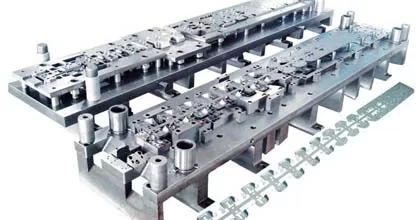

03

Mold Fabrication

Based on your project requirements, we fabricate precision stamping molds by selecting the optimal mold type and material. Our skilled technicians ensure each mold is engineered to withstand high-pressure operations and deliver consistent performance.

-

04

Sample Trial Production and Testing

We initiate a sample trial production to validate our process. Rigorous testing is conducted on prototypes to assess weld integrity, dimensional accuracy, and overall functionality, ensuring readiness for full-scale production.

-

05

Quality Control Process Formulation

Our quality team develops stringent control protocols, implementing ultrasonic and magnetic particle inspections at key stages. Detailed documentation and real-time monitoring ensure every weld meets our high standards and regulatory requirements.

-

06

Production Scheduling

We meticulously schedule production runs to optimize efficiency. Coordinating across departments, we set clear milestones and deadlines, ensuring each stage of the welding process is executed without delay for on-time delivery.

-

07

Raw Material Procurement

Our procurement team sources high-quality base materials from trusted suppliers. We ensure each batch meets strict specifications, providing a reliable foundation for consistent welding performance and overall product durability.

-

08

Down Cutting

In the down cutting stage, materials are precisely cut to the required dimensions. This step minimizes waste and ensures that all sheets are prepared accurately for the subsequent stamping and welding processes.

-

09

Stamping

During the stamping phase, sheets are formed into preliminary shapes using advanced stamping presses. This process creates uniform blanks that serve as the foundation for high-precision laser welding and final product assembly.

-

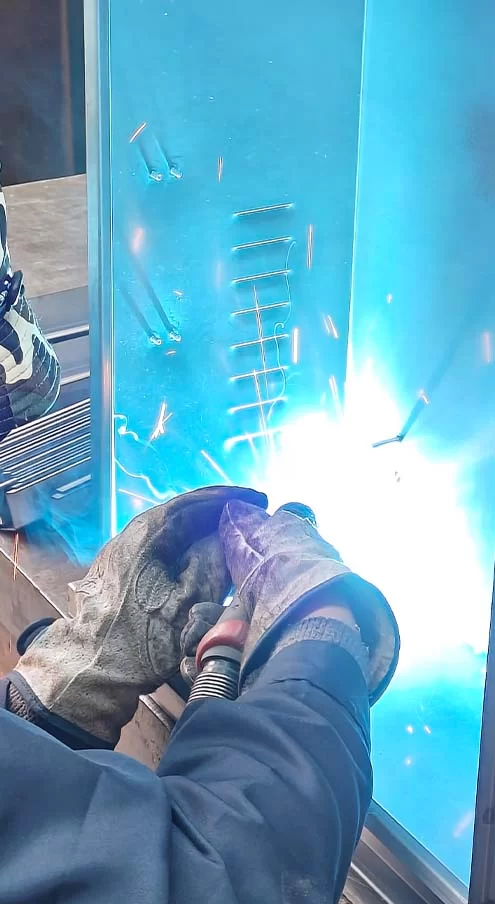

10

Laser Welding

Using cutting-edge laser technology, our system delivers highly focused energy for rapid, precise welds. This process seamlessly fuses metal sheets, ensuring minimal thermal distortion and exceptional joint integrity.

-

11

Quality Inspection

After welding, our quality team performs comprehensive inspections using ultrasonic and magnetic particle testing. Every weld is meticulously examined for consistency, ensuring adherence to rigorous industry standards and flawless product performance.

-

12

Surface Treatment

Our post-weld surface treatment process enhances finish quality by removing minor imperfections. We apply specialized coatings to improve corrosion resistance and aesthetics, ensuring each component meets both functional and visual standards.

-

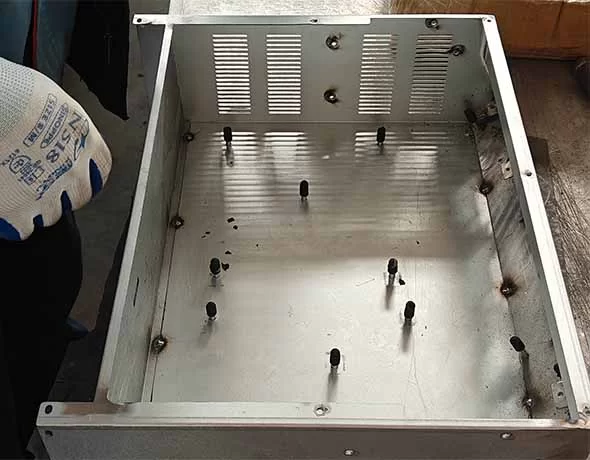

13

Assembly

If required, components are assembled using precision techniques. Our experienced team ensures proper alignment and secure fastening, integrating laser-welded parts seamlessly into the final product with meticulous attention to detail.

-

14

Packaging

After assembly, products are carefully packaged to protect them during transit. We use high-quality, secure packaging methods that preserve product integrity and ensure safe delivery to our customers' locations.

-

15

Pre-shipment Inspection

Before shipment, a final round of inspections is conducted. Our team verifies all dimensions, weld quality, and surface finishes to ensure that every product meets stringent quality criteria before it leaves our facility.

-

16

Order Delivery

Following the successful final inspection, products are dispatched through our reliable logistics network. We ensure timely delivery, keeping you updated on shipment status until the order safely arrives at your specified destination.

-

17

After-sales Service

Our commitment continues post-delivery. We offer comprehensive after-sales support, including returns, exchanges, or replenishment services for any quality issues. Our dedicated team promptly addresses concerns to ensure lasting customer satisfaction.

Metal Laser Welding Parts We Have Produced

At HULK Metal, we have produced a wide array of metal laser welded components—including precision brackets, enclosures, and structural supports. Each product exemplifies our commitment to superior quality and enduring durability.

-

Custom Wall Mount Network Rack

Custom Wall Mount Network RackPartner with HULK Metal for exceptional contract manufacturing of Wall Mount Network Racks. Benefit from our precision engineering, streamlined processes, and rigorous quality control—delivering robust, custom-designed racks that enhance your network infrastructure.

READ MORE

-

18 to 47U Network Server Cabinets

18 to 47U Network Server CabinetsOur 18 to 47U Network Server Cabinets are engineered for modern data centers and telecom environments. Designed to be fully customizable, these cabinets offer robust security, efficient cooling, and optimal cable management—all tailored to your exact specifications.

READ MORE

-

Precision Metal Stamping Parts Manufacturer

Precision Metal Stamping Parts ManufacturerHULK Metal's factory has passed ISO 9001 and ISO 16949 double certification, with rich experience in precision stamping parts production, and is one of the top suppliers in China.

READ MORE

-

Trailer Coupler Factory In China

Trailer Coupler Factory In ChinaWe have an advanced sheet metal factory certified by ISO 9001 and ISO 16949 to meet your trailer coupler manufacturing needs. We provide customers with quality services through perfect supply chain management.

READ MORE

-

Roof Bike Carriers For Cars Factory in China

Roof Bike Carriers For Cars Factory in ChinaIn order to firmly fix the bicycle on the roof, we need to consider the torsion resistance, impact resistance, and other performance that may cause deformation of the bike carriers at multiple angles.

READ MORE

More Results

HULK Metal Sheet Metal Factory

Our state-of-the-art sheet metal factory integrates advanced production lines, skilled technicians, and rigorous quality control, ensuring precise fabrication across stamping, laser cutting, welding, assembly, and surface treatment processes.

Laser Cutting Workshop

Quality Control Center

Surface Treatment Workshop

Stamping Workshop

Laser Welding Workshop

Assembly Workshop

-

Laser Cutting Workshop

Our laser cutting workshop is equipped with state-of-the-art cutting systems that deliver high-speed, precision cuts on various metal sheets. Advanced automation and skilled operators ensure clean, accurate cuts with minimal waste. Comprehensive quality control protocols, including real-time monitoring, verify dimensional accuracy and surface finish. This facility handles diverse material types and thicknesses, providing the flexibility needed for complex projects. Routine equipment maintenance and calibration guarantee optimal performance. The laser cutting workshop's efficiency and reliability are pivotal to our production process, ensuring every piece meets exact specifications for high-quality metal fabrication.

-

Quality Control Center

Our Quality Control Center is equipped with advanced testing instruments and comprehensive inspection procedures that span every stage of production. Detailed quality assessments—including dimensional, surface, and structural evaluations—are performed systematically to ensure products meet strict industry standards. Skilled inspectors employ ultrasonic testing, magnetic particle inspections, and statistical sampling techniques to monitor quality in real time. Data-driven analysis and detailed reporting facilitate immediate corrective actions when deviations occur. Regular audits and continuous training further enhance our inspection processes, ensuring consistent product excellence. This proactive quality management approach guarantees a high delivery pass rate and reliable performance. Our unwavering commitment to precision and excellence in quality control underpins every facet of our metal fabrication operations.

-

Surface Treatment Workshop

Our surface treatment workshop employs advanced powder coating and finishing technologies to enhance both durability and aesthetics. Automated spray lines and precision curing ovens ensure uniform coating thickness and exceptional surface quality across all products. Skilled technicians oversee every stage—from surface preparation to final curing—ensuring optimal adhesion and enhanced corrosion resistance. Rigorous quality control procedures and strict environmental protection measures maintain high standards and regulatory compliance. This workshop's efficient operation and commitment to eco-friendly practices yield superior finishes that extend product lifespan and improve appearance. Continuous investments in innovative technology further reinforce our commitment to excellence, making our surface treatment workshop a vital component of our comprehensive fabrication capabilities.

-

Stamping Workshop

Within our factory, the stamping workshop boasts an extensive range of high-capacity presses that deliver consistent and accurate blank formation. The spacious facility incorporates advanced automation for efficient material handling and rapid cycle times. Experienced operators oversee every process, ensuring that each stamp meets precise tolerances and quality benchmarks. Integrated quality control measures and real-time monitoring systems minimize errors and waste. Designed for high-volume production, the workshop accommodates diverse project requirements with flexibility and reliability. Continuous equipment upgrades and process optimizations further enhance production efficiency, making our stamping workshop a cornerstone of our comprehensive metal fabrication capabilities.

-

Laser Welding Workshop

Our laser welding workshop is at the forefront of precision welding technology. Equipped with advanced laser systems, the facility delivers highly focused energy for rapid and accurate welds across various metal components. Experienced welders collaborate with automated systems to ensure consistent joint integrity and exceptional performance. Comprehensive quality inspections, including ultrasonic and magnetic particle testing, validate the strength and durability of each weld. The workshop supports both small-scale precision projects and high-volume production runs, maintaining stringent tolerances throughout. This commitment to quality and efficiency underpins our reputation for delivering reliable, high-performance metal laser welding solutions that meet demanding industry standards.

-

Assembly Workshop

In our assembly workshop, streamlined production lines ensure that all components are accurately integrated into the final product. Skilled technicians utilize precision tools and advanced methodologies to guarantee proper alignment and secure fastening. The facility is designed for versatility, accommodating various assembly techniques such as welding, riveting, and adhesive bonding. Strict quality control processes, reinforced by regular inspections, ensure that every assembled unit meets the highest standards. Automated tracking systems monitor production progress, while experienced supervisors manage workflow efficiency. This well-organized environment fosters rapid, error-free assembly and significantly contributes to the overall reliability and performance of our metal fabrication services.

Metal Laser Welding Service Moments

Experience the critical moments in our laser welding process—from precise weld execution and accurate dimension measurements to rigorous flatness assessments, ultrasonic testing, and final pre-shipment inspections—ensuring superior quality in every product.

-

Dimension Measurement

State-of-the-art digital measurement systems ensure every weld meets exact dimensional standards for optimal component fit.

-

Flatness Measurement

Advanced precision flatness measurements consistently verify uniform surface alignment, guaranteeing exceptionally high-quality, distortion-free welding outcomes.

-

Pre-shipment Inspection

Final pre-shipment inspections meticulously verify weld quality, dimensions, and finish, ensuring every order meets our stringent standards.

-

Ultrasonic Testing

Cutting-edge ultrasonic testing detects internal weld flaws, ensuring structural integrity and superior performance in every joint.

-

Welding

Advanced laser welding delivers rapid, precise joints with minimal heat distortion for flawless component integration.

Benefits of Choosing HULK Metal's Metal Laser Welding Service

Choosing HULK Metal for metal laser welding ensures access to cutting-edge technology, expert craftsmanship, and comprehensive support. Our solutions deliver unmatched precision, durability, and efficiency, backed by rigorous quality control and responsive after-sales service for your project's success.

-

Factory:

At HULK Metal, our factory is a state-of-the-art facility equipped with advanced laser welding systems and automated production lines. Our expansive production floor, managed by highly skilled professionals, ensures every weld meets stringent quality standards. Continuous investments in technology and process optimization enable rapid production cycles and consistent output. This robust infrastructure allows us to handle complex projects with high precision, ensuring reliable, high-quality welding results across various industrial applications.

-

Experience:

With over 20 years of industry experience, HULK Metal has established itself as a leader in metal laser welding solutions. Our team of seasoned experts brings deep technical knowledge and innovative approaches to every project. Serving multiple industries, we consistently deliver customized solutions that meet exacting specifications. Our extensive experience enables us to tackle complex challenges efficiently and accurately, ensuring superior weld quality and long-term durability. Trust our expertise to transform your designs into flawlessly welded components that enhance performance and reliability.

-

Quality:

Quality is the cornerstone of our metal laser welding service at HULK Metal. We adhere strictly to ISO standards and employ rigorous quality control processes at every production stage. Advanced inspection techniques—including ultrasonic and magnetic particle testing—are integrated into our workflow to ensure consistent weld integrity and precision. Our dedicated quality control team conducts regular audits and real-time monitoring, guaranteeing that every product meets the highest industry benchmarks. This unwavering commitment to quality ensures our welding solutions deliver exceptional performance and long-lasting reliability.

-

Service:

HULK Metal is committed to providing comprehensive service throughout your project lifecycle. From the initial consultation and design review to production and after-sales support, our team is dedicated to delivering a seamless experience. We offer prompt, personalized customer service, ensuring every inquiry is addressed swiftly and effectively. Our well-established supply chain and logistics management guarantee timely delivery and efficient project execution. With our proactive approach to service, you can trust HULK Metal to be a reliable partner dedicated to your success.

Metal Laser Welding Introduction

Explore HULK Metal's Metal Laser Welding Service, where cutting-edge technology meets expert craftsmanship. Our service transforms your designs into durable, precision-welded components, supported by rigorous quality and comprehensive after-sales care.

-

Metal Laser Cutting Means:

At HULK Metal, our metal laser cutting means harnessing advanced laser technology to achieve high-precision cuts on a wide range of metal materials. Our process employs finely tuned laser beams that produce clean, accurate edges with minimal thermal distortion, ideal for intricate patterns and complex designs. Integrated with automated systems and overseen by experienced technicians, our laser cutting capabilities consistently deliver products that meet strict tolerances and high-quality standards. This advanced method is a vital component of our comprehensive metal fabrication solutions, enabling rapid production cycles and exceptional finishing quality.

-

Metal Laser Cutting Application:

Metal laser cutting at HULK Metal is applied across diverse industries including automotive, aerospace, electronics, and construction. Our precision cutting technology is used to create intricate components, prototypes, and large-scale production parts with outstanding accuracy. Suitable for materials ranging from thin sheets to heavy-duty metals, this process ensures versatility and consistent quality. It enables the production of complex designs with smooth edges, reducing the need for extensive secondary finishing. Our expertise in laser cutting ensures each project is executed with the highest precision, contributing to superior performance and durability in the final product.

Choose HULK Metal As Your Partner:

Choosing HULK Metal as your partner means aligning with a company that prioritizes innovation, quality, and customer satisfaction. Our advanced metal laser welding and cutting services are supported by decades of industry experience and a relentless commitment to excellence. We work closely with you from concept to delivery, ensuring every project is tailored to your specific requirements. Our state-of-the-art facilities, skilled professionals, and rigorous quality control processes guarantee reliable and cost-effective solutions. With dedicated after-sales support and a proven track record of success, HULK Metal stands ready to transform your design ideas into precision-engineered products that exceed expectations.

Feel free to contact us for a personalized quote and discover how HULK Metal's Metal Laser Welding Service can elevate your project with unmatched precision and quality.

Articles Related to Metal Laser Cutting Services

Explore our insightful articles on metal laser cutting, featuring industry trends, technological innovations, and best practices. Gain valuable knowledge and expert tips to enhance your metal fabrication projects with precision and efficiency.