Explore our comprehensive guide on network server accessories. Learn about the concept, common types—including their materials, key parameters, and purchasing considerations—and discover the critical factors when choosing an OEM factory for production. En

Your Ultimate Resource on Network Server Accessories – Types, Specifications, and OEM Selection

Common Network Server Accessories: Concepts, Types, and How to Choose the Right OEM Factory

-

Home>

-

Blog>

-

Technology>

Common Network Server Accessories: A Complete Guide

Network server accessories are the unsung heroes of any data center, providing the structure, organization, and environmental control needed for optimal performance. In this guide, we define the concept of network server accessories in approximately 300 words. We then dive into a detailed discussion (around 2000 words) of common types of network server accessories, including racks, blank panels, cable management systems, brackets, trays, and cabinets. For each accessory type, we outline the materials used, key technical parameters (such as dimensions, thickness, tolerances, load capacities, and ventilation features), and important purchasing considerations. Finally, we cover (roughly 1000 words) the essential factors to evaluate when selecting an OEM factory to produce these accessories—focusing on experience, production capabilities, quality control, customization, supply chain integration, transparent pricing, and communication, along with after-sales support for quality issues or shipment shortages. (When mentioned, HULK Metal is noted for its advanced OEM manufacturing capabilities and dependable service.) This guide is designed for IT professionals and data center managers looking to build a robust, scalable, and efficient network infrastructure.

1. Understanding Network Server Accessories

Network server accessories form the critical infrastructure that supports and enhances the operation of data centers. In essence, these accessories are not standalone gadgets—they are the building blocks that ensure your servers, switches, and networking devices are securely housed, well-organized, and properly cooled. At the core of a well-designed data center is a system of components that work in harmony to protect sensitive IT equipment and optimize operational efficiency.

These accessories include a range of items such as server racks, blank panels, cable management systems, mounting brackets, trays, and cabinets. Each plays a distinct role: server racks provide the overall framework; blank panels cover unused spaces, thereby promoting better airflow and security; cable management systems keep cables organized to prevent tangling and improve cooling; mounting brackets secure equipment firmly; trays offer platforms for peripherals or additional equipment; and cabinets provide a complete enclosure with added security and environmental control.

The importance of these accessories extends beyond mere aesthetics. A well-organized rack system helps prevent overheating by ensuring that cool air circulates properly, reduces the risk of physical damage to expensive hardware, and facilitates easier maintenance and upgrades. As data centers continue to evolve in complexity and scale, investing in high-quality network server accessories becomes essential to maintain operational uptime and future-proof your infrastructure.

Understanding the role and importance of each accessory is the first step in creating an efficient, scalable, and reliable data center. It also lays the groundwork for selecting the right OEM factory that can manufacture these components to meet rigorous standards of quality and precision.

2. Common Network Server Accessories: Types, Materials, Key Parameters, and Purchasing Considerations

In a data center, network server accessories are as crucial as the servers themselves. In this section, we'll detail the common types of accessories, discuss the materials used in their construction, explain the key technical parameters for each, and highlight important considerations to keep in mind when purchasing these components.

2.1 Server Racks

Concept and Functionality:

Server racks serve as the primary enclosures in data centers. They provide a structured framework to house servers, switches, and other critical equipment while maximizing space and ensuring efficient airflow.

Common Materials:

- Steel:

The most widely used material for its strength and durability. Typical plate thickness ranges from 1.5 mm to 2.5 mm. Steel racks are known for their robust construction and long service life.

- Aluminum:

Preferred in environments where weight is a concern. Aluminum racks are lighter, offer natural corrosion resistance, and provide a modern, sleek aesthetic.

- Composite Materials:

In some specialized cases, composites are used to achieve a balance between strength and weight, though they are less common.

Key Parameters:

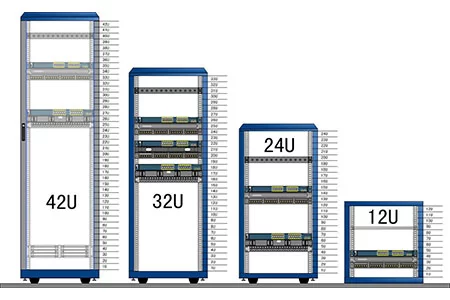

- Height (Rack Units):

Racks are measured in “U” units, where 1U equals 1.75 inches (44.45 mm). Common configurations include 42U or 45U racks, offering ample space for a variety of equipment.

- Width:

Standard widths usually range between 600 mm and 800 mm. Precision is essential, with tolerances maintained within ±0.2 mm.

- Depth:

Racks can vary in depth from 600 mm in smaller installations to 1200 mm or more in larger data centers.

- Load Capacity:

Racks must be capable of supporting heavy equipment. Critical structural components are engineered to withstand significant loads, sometimes 50 kg or more per rack unit.

Purchasing Considerations:

- Compatibility:

Ensure that the rack dimensions match your equipment's specifications.

- Ease of Maintenance:

Consider racks that offer integrated cable management and tool-less access for efficient maintenance.

- Aesthetic and Functional Integration:

The rack's design should enhance both the look and performance of your data center.

2.2 Blank Panels

Concept and Functionality:

Blank panels are used to cover unused spaces within server racks. Their primary functions are to maintain a professional appearance, enhance airflow, and protect internal components from dust and interference.

Common Materials:

- Steel:

Offers superior strength and durability. Thickness is typically between 1.5 mm and 2.5 mm, making them ideal for robust applications.

- Aluminum:

Provides a lighter alternative with excellent corrosion resistance, suited for modern data centers.

- High-Grade Plastics:

PVC or polycarbonate options are available for cost-effective and lightweight applications.

Key Parameters:

- Dimensions:

Designed to fit specific rack spaces (e.g., 1U, 2U, or multi-U panels). Standard sizes are determined by the rack's width (600–800 mm) and depth (800–1200 mm).

- Finishing:

Surface treatments like powder coating enhance durability and improve aesthetics.

- Ventilation:

Some panels are designed with perforations (typically 5 mm to 10 mm in diameter) to maintain proper airflow.

Purchasing Considerations:

- Fit and Finish:

Panels must match the rack dimensions exactly with minimal tolerances to avoid gaps.

- Application Needs:

Choose ventilated panels for environments with high thermal loads, or fixed panels for static setups.

- Durability:

Consider the operational environment—harsher conditions may require thicker materials or special coatings.

2.3 Cable Management Systems

Concept and Functionality:

Cable management systems organize and secure cables within the server rack, ensuring that wiring is neat, accessible, and does not interfere with cooling. Effective cable management minimizes downtime and prevents signal interference.

Common Materials:

- Metal (Steel or Aluminum):

Used for rigid cable trays and channels, providing robust support.

- Plastics:

High-grade plastics are popular for their lightweight and flexibility, particularly in smaller or less load-intensive applications.

- Composites:

Occasionally used for high-performance cable management solutions that require a balance of strength and low weight.

Key Parameters:

- Design:

Features include integrated channels, clips, and trays designed to accommodate various cable sizes.

- Dimensions:

Must be sized to fit within the standard rack width and depth; channels typically have a width of 50–100 mm.

- Load Capacity:

Cable management systems must support the weight of bundled cables without sagging.

- Airflow Considerations:

Designs that promote airflow help maintain optimal cooling.

Purchasing Considerations:

- Cable Volume:

Ensure the system can handle your cable density and future expansions.

- Ease of Installation:

Look for designs with tool-less installation features to simplify setup and maintenance.

- Flexibility:

Consider systems that can be reconfigured easily to adapt to changing needs.

2.4 Mounting Brackets

Concept and Functionality:

Mounting brackets secure servers, switches, and other equipment within a rack. They ensure that devices are held firmly in place and maintain proper alignment and airflow.

Common Materials:

- Steel:

Offers excellent load-bearing capacity and durability.

- Aluminum:

Provides a lightweight, corrosion-resistant alternative suitable for many installations.

- Reinforced Plastics:

Used in some applications where weight reduction is a priority without significantly compromising strength.

Key Parameters:

- Dimensions:

Must align with the standard dimensions of the rack and the equipment's mounting points.

- Load Capacity:

Critical for supporting heavy equipment; often designed to handle loads of 50 kg or more.

- Installation Features:

May include tool-less locking mechanisms and pre-drilled holes (commonly 5 mm in diameter) to ensure easy and secure mounting.

Purchasing Considerations:

- Compatibility:

Ensure the brackets are compatible with your equipment's mounting requirements.

- Stability:

Look for designs that offer high stability and minimal flexing.

- Ease of Use:

Consider brackets that simplify installation and maintenance.

2.5 Trays

Concept and Functionality:

Trays provide a platform for mounting peripheral devices or organizing smaller components within the rack. They help maximize space efficiency and improve the overall organization of the server environment.

Common Materials:

- Steel and Aluminum:

Commonly used due to their strength, with thicknesses typically ranging from 1.5 mm to 2.5 mm.

- Composite Materials:

Sometimes used in specialized trays where weight reduction is important.

Key Parameters:

- Dimensions:

Trays are designed to fit within the standard rack width and depth, often customized to specific requirements.

- Load Capacity:

Must support the weight of the mounted equipment or components.

- Design Features:

May include integrated cable management, ventilation slots, or accessory mounting points.

Purchasing Considerations:

- Functionality:

Ensure that the tray design meets the specific needs of your installation, whether for equipment mounting or cable organization.

- Durability:

Choose trays that offer robust support and long-term reliability.

- Integration:

Consider trays that integrate seamlessly with other rack components for a cohesive system.

2.6 Cabinets

Concept and Functionality:

Server cabinets are complete enclosures that house network server racks, offering added security, environmental control, and improved aesthetics. They protect the equipment from external hazards while providing an organized framework for the entire data center.

Common Materials:

- Steel:

The preferred material for its strength and durability, ensuring maximum protection.

- Aluminum:

Used for lighter applications where ease of installation and a modern appearance are desired.

- Composite Materials:

Occasionally utilized for specialized applications balancing durability with weight reduction.

Key Parameters:

- Dimensions:

Cabinets are often built to standard rack sizes but can be customized to meet specific spatial requirements.

- Security Features:

Include lockable doors, secure panels, and robust construction to protect sensitive equipment.

- Cooling Integration:

Cabinets often have provisions for integrated cooling systems or the ability to accommodate external cooling solutions.

- Tolerances:

Precision in manufacturing is critical, with tolerances maintained within ±0.2 mm to ensure a perfect fit.

Purchasing Considerations:

- Security Needs:

Evaluate the level of protection required for your equipment.

- Environmental Control:

Consider cabinets with integrated cooling or climate control features if your data center operates in challenging environments.

- Scalability:

Ensure the cabinet design allows for future expansion as technology and requirements evolve.

3. Key Considerations When Choosing an OEM Factory for Common Network Server Accessories

When it comes to contract manufacturing your network server accessories, selecting the right OEM factory is crucial to ensure that every component meets your stringent quality and performance standards. This section outlines the essential factors to consider when choosing an OEM partner for the production of network server accessories.

3.1 Experience and Technical Expertise

Importance:

Experience in the industry is a strong indicator of an OEM's ability to deliver high-quality products consistently. A factory with a proven track record in metal processing, sheet metal fabrication, and producing network server accessories will have the technical know-how and refined processes needed to handle complex orders.

What to Look For:

- Industry Track Record:

Research the OEM's history and their experience in producing similar products such as racks, blank panels, cable management systems, mounting brackets, trays, and cabinets.

- Specialized Skills:

Ensure the manufacturer specializes in the types of accessories you need. Their technical expertise should extend to both standard and custom solutions.

- Engineering Support:

A robust engineering team that can work closely with your design team to refine specifications, address production challenges, and implement improvements is invaluable.

- OEM Reputation:

Look for testimonials or references that demonstrate the OEM's reliability and quality performance.

Choosing an experienced OEM partner minimizes risk and helps ensure that your accessories are manufactured with the precision and quality required for a high-performance data center.

3.2 Advanced Production Capabilities

Importance:

The quality of your network server accessories heavily depends on the OEM's production capabilities. Advanced manufacturing processes and modern equipment are crucial for achieving the tight tolerances and high standards demanded by data centers.

What to Look For:

- State-of-the-Art Equipment:

The factory should employ modern laser cutting, CNC bending, and automated stamping systems. These technologies ensure that each component is fabricated with precision—tolerances as tight as ±0.2 mm are ideal.

- Material Handling:

Ensure the OEM is proficient in processing a range of materials (such as steel, aluminum, high-grade plastics, and composites) with thicknesses typically between 1.5 mm and 2.5 mm.

- Production Scalability:

The OEM must be capable of handling both small prototype batches and large-scale production runs efficiently.

- Customization Flexibility:

A flexible production line that can easily adapt to custom designs and integrated features (like enhanced ventilation or cable management integration) is a significant advantage.

- Quality Assurance:

Advanced production is often coupled with rigorous quality control systems, ensuring that every product meets specified standards.

An OEM with advanced production capabilities ensures that your network server accessories are built with precision and consistency, resulting in reliable and durable components.

3.3 Rigorous Quality Control

Importance:

Quality control is the cornerstone of dependable manufacturing. In a data center environment, even minor defects can lead to significant issues. Ensuring that your accessories meet stringent quality standards is non-negotiable.

What to Look For:

- In-Process Inspections:

The OEM should conduct continuous quality checks throughout the production process. This includes verifying dimensions, load capacity, and thermal performance.

- Final Testing:

Every finished product should undergo comprehensive testing to ensure it meets all technical and safety standards.

- Certifications:

International certifications like ISO 9001 are a strong indicator of a robust quality control system.

- Traceability:

The ability to track components from raw material to finished product adds an extra layer of assurance that any defects can be quickly identified and rectified.

An OEM partner with stringent quality control measures will help ensure that every network server accessory functions reliably, thereby protecting your data center infrastructure from potential failures.

3.4 Supply Chain Integration and Logistics

Importance:

A well-integrated supply chain minimizes delays, reduces costs, and ensures that your network server accessories are delivered on time and to the highest quality.

What to Look For:

- End-to-End Management:

The OEM should manage the entire process—from raw material sourcing and production to packaging and shipping.

- Efficient Inventory Systems:

Robust inventory and production management systems are essential, especially for large orders.

- Timely Delivery:

A reliable logistics network that ensures on-time delivery is crucial to keep your project on schedule.

- Cost Efficiency:

An integrated supply chain often translates into lower production costs and fewer delays, contributing to overall cost-effectiveness.

Strong supply chain integration ensures that every step of production is coordinated smoothly, minimizing disruptions and ensuring that your network server accessories are produced and delivered on schedule.

3.5 Transparent Pricing and Cost Effectiveness

Importance:

Understanding the complete cost structure of manufacturing your network server accessories is essential for making an informed decision. Transparent pricing helps you assess the true value of your investment.

What to Look For:

- Detailed Quotations:

The OEM should provide clear, itemized cost breakdowns that include raw material, labor, finishing, and logistics.

- Competitive Pricing:

Compare proposals from several OEM partners, but remember that the lowest bid is not always the best if it compromises quality.

- Total Cost of Ownership:

Consider not only the initial cost but also long-term savings from reduced maintenance, fewer downtimes, and extended product life.

- Cost Transparency:

Transparent pricing builds trust and ensures there are no unexpected expenses down the line.

Clear and competitive pricing is a vital indicator that the OEM partner values transparency and is committed to providing high-quality products at a fair price.

3.6 Communication and After-Sales Support

Importance:

Effective communication is essential throughout the production process to ensure that everything runs smoothly. Additionally, robust after-sales support is critical for addressing any issues that arise post-production.

What to Look For:

- Dedicated Account Manager:

A single point of contact who understands your project and coordinates the production process is invaluable.

- Regular Updates:

The OEM should provide proactive communication regarding production progress, potential delays, and any changes or modifications.

- Responsive Support:

In the event of any quality issues or shipment shortages, the OEM should have clear policies for returns, exchanges, or replenishments. (For instance, HULK Metal offers after-sales support for quality issues and short shipments.)

- Clear Communication Channels:

Ensure that the OEM is accessible and responsive, and that any issues are resolved quickly and efficiently.

Strong communication and dedicated after-sales support can mitigate risks and ensure that your production runs smoothly from start to finish.

3.7 Summary of OEM Selection Factors

In summary, when choosing an OEM factory to produce your network server accessories, consider the following key factors:

- Experience and Technical Expertise:

An OEM with a strong track record and specialized knowledge in producing network server accessories.

- Advanced Production Capabilities:

Modern, high-precision equipment and scalable production processes are essential.

- Rigorous Quality Control:

Continuous inspections, final testing, and industry certifications ensure product reliability.

- Supply Chain Integration:

A fully integrated, efficient supply chain minimizes delays and maintains quality.

- Transparent Pricing:

Detailed, competitive cost structures help you assess the true value of your investment.

- Effective Communication and After-Sales Support:

Dedicated support throughout the process ensures smooth operations and quick resolution of issues.

By evaluating these factors thoroughly, you can choose an OEM partner that not only meets your technical requirements but also supports your long-term business objectives.

Final Thoughts

Network server accessories are critical to the performance, reliability, and scalability of your data center. From racks and blank panels to cable management systems, mounting brackets, trays, and cabinets, every component must be engineered to exacting standards. When selecting an OEM factory to produce these essential accessories, careful consideration of the factors outlined above will ensure that you receive products that are robust, precisely manufactured, and perfectly suited to your needs.

By focusing on experience, advanced production capabilities, rigorous quality control, customization flexibility, integrated supply chains, transparent pricing, and strong communication with reliable after-sales support, you lay the foundation for a data center infrastructure that can meet today's demands and adapt to tomorrow's challenges.

Remember, a well-chosen OEM partner is not just a supplier—it is a strategic ally in building a future-proof data center. With every well-engineered component, you enhance your network's efficiency and reliability, ultimately ensuring the long-term success of your IT operations.

Thank you for reading this comprehensive guide on common network server accessories and the essential factors for choosing a suitable OEM factory for their production. We hope this resource equips you with the insights and practical tips needed to make an informed decision that supports the growth and stability of your data center.

Contact us today to discuss your production requirements and receive a competitive, custom-tailored quote from an OEM partner dedicated to excellence in network server accessory manufacturing.

Article Navigation

Article Navigation

Industries

Foundries

-

November.21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October.18, 2024

HULK Metal Fabrication

READ MORE

-

February.28, 2025

Network Server Tray Solutions for Enhanced Data Center Efficiency

READ MORE

-

February.26, 2025

A Comprehensive Guide to Network Server Racks

READ MORE

-

February.24, 2025

Superior Network Server Cable Management Solutions by HULK Metal

READ MORE

-

February.21, 2025

1U, 2U 18U, 42U, What That Mean

READ MORE

-

February.21, 2025

How Should You Choose A Suitable OEM Factory to Produce Your Network Server Accessories

READ MORE