HULK Metal delivers unparalleled contract manufacturing for Network Server Cable Management solutions. In this blog, we provide a detailed overview of the concept, discuss vital parameters, explore various types and materials, and outline key factors for

Optimized Solutions for Network Server Cable Management Excellence

Unlocking Excellence in Network Server Cable Management

-

Home>

-

Blog>

-

Technology>

Superior Network Server Cable Management Solutions by HULK Metal

Comprehensive Overview of Network Server Cable Management

Network Server Cable Management is a critical solution designed to organize, secure, and protect cables within network infrastructures. Its purpose is to reduce clutter, improve airflow, and simplify maintenance in data centers and server rooms. Efficient cable management not only ensures operational safety but also enhances system performance. At HULK Metal, our contract manufacturing capabilities enable us to produce high-quality cable management products that meet diverse customer specifications. Whether you require customized designs or large-volume production, our experienced team and advanced production capacity are ready to deliver. Contact us now for a free consultation and quote!

Key Parameters of Network Server Cable Management

When it comes to Network Server Cable Management, several key parameters determine the product's effectiveness, durability, and suitability for various network environments.

First and foremost is capacity:

the design must accommodate varying cable sizes and volumes, ensuring that even high-density setups can be organized efficiently. At HULK Metal, our engineered solutions offer scalable capacity options that allow for both small-scale and extensive network implementations.

Another critical parameter is durability.

In environments such as data centers where heat and constant movement are common, materials and construction techniques must ensure long-lasting performance. Our production processes incorporate rigorous quality control, employing robust manufacturing methods that reduce wear and tear over time. Factors such as thermal resistance and corrosion protection are integrated into our designs to extend the product lifecycle even under challenging conditions.

Flexibility and modularity are also significant.

A cable management system should be adaptable to various layouts and capable of being reconfigured as network demands evolve. HULK Metal's products are designed with modular components that can be easily expanded or re-arranged, providing both immediate utility and future-proofing your installation.

Aesthetics and design innovation play a key role as well.

A neat and well-organized cable management system not only performs functionally but also enhances the visual environment of server rooms. Our design teams focus on creating sleek, unobtrusive solutions that integrate seamlessly into modern network infrastructures while offering optimum performance.

The ease of installation and maintenance cannot be overstated.

A well-thought-out cable management system should allow technicians to quickly access and service cables without disrupting overall operations. Our solutions are engineered for straightforward installation procedures, ensuring that maintenance teams can perform routine checks and repairs efficiently. Clear labeling and intuitive layouts further reduce the risk of human error during installations and service interventions.

Safety standards and compliance are fundamental parameters.

Given the importance of network reliability and data protection, our cable management solutions comply with international safety and performance standards. This commitment to quality ensures that every product leaving our production line is fit for critical applications, providing peace of mind to our clients.

Finally, cost-effectiveness and customization are key.

Balancing quality with competitive pricing is essential in today's market. At HULK Metal, our robust supply chain and extensive factory resources allow us to deliver tailor-made solutions that meet your specific needs without compromising on cost efficiency. Our comprehensive service—from material sourcing through to packaging and logistics—ensures that every project is managed seamlessly.

Ready to optimize your network? Contact us today to discuss how our advanced cable management solutions can meet your technical and budgetary requirements.

Common Types, Their Pros, Cons, and Applications

Network Server Cable Management systems come in a variety of types, each tailored to specific needs and environments. Understanding these types helps in selecting the best solution for your server room or data center.

Cable Trays and Ladders:

Pros:

Offer robust support for a large volume of cables

Provide excellent airflow and easy access for maintenance

Durable construction suitable for heavy-duty installations

Cons:

Can be bulky and require more space

Installation may be more complex in existing infrastructure

Applications:

Ideal for large data centers and industrial environments where robust cable support and ventilation are priorities. Their design facilitates heat dissipation, making them a top choice for high-performance networks.

Cable Ducts and Conduits:

Pros:

Provide a secure pathway for cables

Protect cables from environmental hazards such as dust and moisture

Offer a neat, enclosed appearance

Cons:

Less flexible compared to open trays

May be challenging to modify once installed

Applications:

These systems are often used in environments where safety and protection from physical damage are paramount. They are a common choice in corporate and commercial settings, where aesthetic appeal and cable security are both essential.

Cable Ties and Velcro Straps:

Pros:

Inexpensive and easy to install

Versatile for bundling and organizing cables

Minimal installation time and adaptable to any layout

Cons:

Can become over-tightened, potentially damaging cables

Less professional appearance if not managed correctly

Applications:

Best suited for smaller installations or as a supplementary solution to more structured cable management systems. They offer quick fixes and temporary organization while permanent solutions are being implemented.

Cable Management Panels and Racks:

Pros:

Designed for high-density cable environments

Offer structured routing and organization

Enhance accessibility for maintenance and troubleshooting

Cons:

May require additional planning and space

Higher initial investment cost

Applications:

Used extensively in enterprise-level data centers and server rooms where organized routing and ease of access are critical. These systems allow for efficient cable segregation and reduce the risk of tangled wires and potential downtime.

Custom Fabricated Solutions:

Pros:

Fully tailored to specific customer requirements

Integrates seamlessly with existing infrastructure

Can address unique challenges not met by off-the-shelf products

Cons:

Longer lead times compared to standard products

Potentially higher cost due to customization

Applications:

These solutions are ideal for clients with unique or complex network environments. HULK Metal excels in offering bespoke cable management systems that perfectly match your technical specifications and operational needs.

Throughout the design and manufacturing process, several common parameters such as load capacity, material strength, thermal resistance, and ease of assembly are considered. At HULK Metal, our production capabilities allow us to incorporate these design factors into every product we manufacture. We use state-of-the-art production equipment that emphasizes precision and consistency while maintaining a focus on scalability and customization.

If you're looking to streamline your network infrastructure with the right cable management solution, our experienced team is ready to help. Get in touch to receive a personalized consultation and quote!

Materials Used in Network Server Cable Management: Advantages and Disadvantages

The choice of material is critical to the performance and longevity of Network Server Cable Management systems. Various materials offer unique advantages and disadvantages based on their physical properties, environmental resistance, and overall cost-effectiveness.

Aluminum:

Advantages:

Lightweight and resistant to corrosion

Excellent thermal conductivity, aiding in heat dissipation

High strength-to-weight ratio, making it ideal for robust installations

Disadvantages:

Higher production costs compared to some plastics

Can be prone to scratches if not properly coated

Plastics (PVC, Polycarbonate):

Advantages:

Cost-effective and highly versatile

Easy to mold into various shapes and sizes

Resistant to chemicals and moisture

Disadvantages:

Lower heat resistance compared to metals

May lack the structural integrity required for heavy cable loads in high-density environments

Steel:

Advantages:

Extremely durable and capable of handling heavy loads

Provides superior protection for cables in industrial applications

Resistant to physical impact and deformation

Disadvantages:

Heavier and may require additional support structures

Susceptible to rust if not properly treated or coated

Fiber-Reinforced Polymers (FRP):

Advantages:

Combines the benefits of plastics and composites, offering high strength and corrosion resistance

Lightweight yet durable, making it suitable for modern data centers

Offers design flexibility for customized solutions

Disadvantages:

Can be more expensive than traditional plastics

Requires specialized manufacturing processes which may extend production times

Each material is selected based on the intended application and environmental conditions. At HULK Metal, we combine extensive material research with state-of-the-art manufacturing techniques to produce cable management systems that meet the highest standards of performance and durability. Whether you need a lightweight solution for small-scale networks or a heavy-duty system for industrial applications, our products are engineered to deliver consistent quality and reliability.

Ready to choose the right material for your network needs? Reach out today for expert advice and a custom solution!

Key Considerations When Choosing a Contract Manufacturer for Network Server Cable Management

Selecting the right contract manufacturer for Network Server Cable Management is a decision that can significantly affect your project's success. Here are the crucial factors you should consider when making this important choice:

Experience and Expertise:

A manufacturer with a proven track record in producing high-quality cable management systems will be able to deliver products that meet stringent quality standards. Look for companies that have a deep understanding of the technical parameters and design innovations required for effective network cable management. At HULK Metal, our decades of experience and specialized teams in production, quality control, and design ensure that every product is engineered to perfection.

Production Capabilities and Equipment:

The production facility should be equipped with advanced machinery that guarantees precision and consistency. Modern production equipment not only increases efficiency but also allows for a high degree of customization. While specific equipment brands may vary, the focus should be on the facility's overall capacity to handle various production scales—from small prototype batches to large-volume manufacturing. HULK Metal's extensive network of factories and state-of-the-art production lines is designed to meet diverse customer requirements without compromising quality.

Quality Assurance and Compliance:

Quality control is essential in network infrastructure components. Ensure the manufacturer follows international quality standards and has a robust quality assurance process in place. This includes regular inspections, adherence to safety certifications, and a commitment to continuous improvement. A manufacturer that prioritizes quality will not only produce reliable products but will also offer comprehensive aftersales services such as returns, replacements, and additional support if issues arise. HULK Metal prides itself on a rigorous quality control process that guarantees every batch meets or exceeds industry standards.

Customization and Flexibility:

Every network installation has unique requirements. A contract manufacturer should be flexible enough to accommodate custom designs, specific material requests, and varied production volumes. Ask whether the manufacturer can provide tailored solutions based on your detailed technical drawings and specifications. At HULK Metal, our engineering team collaborates closely with clients to develop bespoke solutions that fit perfectly into their network design while offering future scalability.

Supply Chain Integration:

An efficient supply chain is crucial for meeting deadlines and ensuring consistent product availability. The ideal manufacturer should have a well-integrated supply chain—from raw material sourcing and production to quality control, packaging, and logistics. This integration minimizes delays and ensures that production runs smoothly. HULK Metal leverages a comprehensive supply chain network, including dedicated teams for procurement, finance, technical support, production, quality assurance, shipping, and aftersales services. This end-to-end control translates into reliable delivery schedules and consistent product quality.

Cost-Effectiveness and Pricing Transparency:

Budget considerations are always critical. While the cheapest option might seem attractive, it is important to evaluate the total value offered, including quality, reliability, and aftersales support. Request detailed quotes and understand the cost breakdown. Transparent pricing models that do not hide additional fees are a good indicator of a reputable manufacturer. With HULK Metal, you receive competitive pricing that reflects our commitment to quality and service, without hidden costs. Our pricing strategy is designed to provide maximum value for every dollar spent.

Communication and Customer Support:

Effective communication is key during every stage of the manufacturing process. From initial consultation through design, production, and delivery, a manufacturer should provide clear, consistent communication channels. Look for companies that offer dedicated project managers or support teams that can address any queries promptly. HULK Metal is renowned for its responsive customer service; our project managers ensure that every client receives timely updates and solutions tailored to their needs.

After-Sales Services and Warranty:

A reliable contract manufacturer stands behind its products. Inquire about after-sales support, warranties, and policies for handling defects or discrepancies in product quality. A comprehensive warranty and responsive aftersales service can save you significant time and expense in the long run. At HULK Metal, we back our products with strong warranty policies and an aftersales team that is always ready to assist with replacements, repairs, or additional orders.

Industry Reputation and Client References:

Research the manufacturer's reputation within the industry. Look for testimonials, case studies, and references from previous clients. Positive feedback and a long list of satisfied customers are strong indicators of a manufacturer's reliability. HULK Metal's longstanding presence in the market and extensive portfolio of successfully delivered projects speak volumes about our capability to meet complex cable management requirements.

Innovation and R&D Investment:

The field of network cable management is evolving rapidly, and manufacturers that invest in research and development can offer innovative solutions that address future challenges. Ask about the company's commitment to continuous improvement and how it stays abreast of industry trends. HULK Metal continually invests in R&D to enhance our product designs, improve production efficiency, and develop innovative solutions that provide our clients with a competitive edge.

Choosing the right contract manufacturer is not just about cost—it's about forming a partnership that can support your long-term business goals. Evaluate each of these factors carefully and consider how they align with your project's specific needs. A manufacturer like HULK Metal, with its comprehensive supply chain, state-of-the-art production facilities, robust quality assurance, and unwavering commitment to customer support, can provide the perfect balance of quality, customization, and cost-effectiveness.

If you are ready to elevate your network infrastructure with a partner who truly understands the nuances of cable management. Our team of experts is here to answer your questions, provide detailed consultations, and deliver a custom solution that exceeds your expectations.

Article Navigation

Article Navigation

Industries

Foundries

-

November.21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October.18, 2024

HULK Metal Fabrication

READ MORE

-

February.21, 2025

Optimized Network Server Blank Panel Solutions for Modern Data Centers

READ MORE

-

February.21, 2025

Choose a Suitable OEM Factory to Produce Your Network Server Racks

READ MORE

-

February.21, 2025

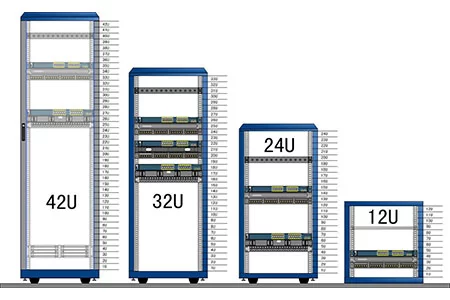

1U, 2U 18U, 42U, What That Mean

READ MORE