In this in-depth blog post, we explore every facet of Network Server Trays—vital components for modern data centers. We begin with a comprehensive overview, then dive into detailed parameters (including exact measurements such as plate thickness and width

Elevate Your Server Infrastructure with Precision-Engineered Trays

The Ultimate Guide to Network Server Trays: Performance, Materials, and Manufacturing Excellence

-

Home>

-

Blog>

-

Technology>

Network Server Tray Solutions for Enhanced Data Center Efficiency

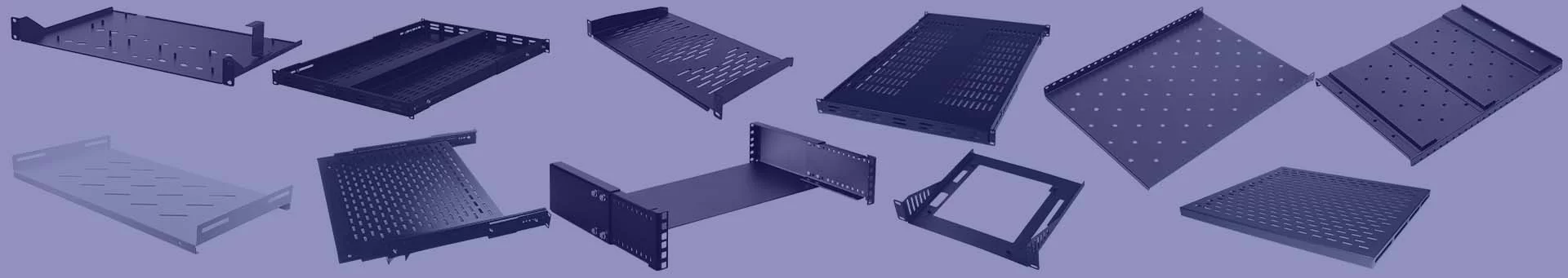

In this in-depth blog post, we explore every facet of Network Server Trays—vital components for modern data centers. We begin with a comprehensive overview, then dive into detailed parameters (including exact measurements such as plate thickness and width), explore common tray types with their advantages, disadvantages, and applications, and analyze the materials used in production. Finally, we outline key considerations when selecting a contract manufacturing partner. At HULK Metal, our advanced production capabilities and integrated supply chain ensure each tray meets the highest quality standards while offering customizable, robust solutions.

Comprehensive Overview of Network Server Trays

Network Server Trays are essential components designed to organize, support, and secure networking equipment within modern data centers. These trays provide a stable platform for mounting servers, switches, and other critical hardware while ensuring optimal airflow and cable management. Engineered for precision, a well-designed tray enhances both the structural integrity and aesthetic appeal of server racks. At HULK Metal, we manufacture trays that adhere to strict dimensional tolerances and quality standards. Our trays are available in various configurations to meet the diverse requirements of small-scale server rooms and large data centers alike. The robust construction of our products not only minimizes vibration and equipment movement but also contributes to improved cooling efficiency and easier maintenance. With customization options available—from specific dimensions to integrated cable management features—our Network Server Trays are built to offer long-lasting performance and reliability.

Important Parameters of Network Server Trays

When evaluating Network Server Trays, precise design parameters are crucial to ensure optimal performance, ease of installation, and long-term durability in a data center environment. One of the most critical factors is the tray thickness. Our trays are typically manufactured with thicknesses ranging from 1.5 mm to 2.5 mm. For instance, a standard model might feature a 2.0 mm thick tray, balancing strength with weight considerations to provide a rigid yet manageable platform for equipment mounting.

Dimensions are equally important.

Common tray widths range from 450 mm to 600 mm, while depths can vary from 600 mm up to 1200 mm. A popular configuration might include a tray that measures 600 mm in width by 800 mm in depth, designed to fit standard server racks seamlessly. Precise tolerances are maintained during production—often within ±0.2 mm—to ensure each tray fits perfectly, reducing the risk of misalignment that can lead to equipment instability or compromised airflow.

Edge Finishing and Mounting Features

play a significant role in the tray's overall functionality. Smooth, rounded edges not only enhance safety during handling but also contribute to a neat appearance in data centers. Integrated mounting brackets and pre-drilled holes ensure that the tray can be securely attached to the rack frame, facilitating quick installation and removal during maintenance. Specific mounting hole diameters are typically standardized at around 5 mm to accommodate industry-standard fasteners.

Another Key Parameter is load capacity.

Network Server Trays must support the weight of multiple pieces of equipment without sagging or bending. Our products are engineered to withstand load capacities of up to 50 kg per tray, ensuring reliable performance even in high-density installations. This robust load-bearing capability is critical in data centers where equipment density and reliability are paramount.

Thermal Management is also a vital consideration.

The design of the tray should promote proper airflow to dissipate heat generated by high-performance servers and networking hardware. Many of our trays incorporate ventilation slots or perforations, typically 5 mm to 10 mm in diameter, strategically placed to enhance cooling efficiency without compromising structural integrity.

Material Coatings and Finishes further enhance the tray's performance.

A high-quality powder-coated finish not only improves the tray's resistance to corrosion but also contributes to a sleek, professional appearance. Coatings are applied to achieve a uniform finish that can withstand the rigors of a data center environment, including temperature fluctuations and exposure to cleaning chemicals.

Customization Options allow clients to tailor trays to specific needs.

Beyond standard sizes, options such as custom widths, depths, and integrated cable management channels can be incorporated to meet unique data center configurations. By offering these customizable parameters, HULK Metal ensures that every tray not only meets technical specifications but also aligns with the aesthetic and functional demands of modern server environments.

In summary, the key parameters of a high-quality Network Server Tray include precise thickness (typically 1.5–2.5 mm), standard dimensions (450–600 mm in width and 600–1200 mm in depth), stringent tolerance levels (±0.2 mm), integrated mounting features, robust load capacity (up to 50 kg), effective thermal management through ventilation, and durable, attractive coatings. These meticulously engineered features guarantee that our trays offer outstanding performance, reliability, and visual appeal in even the most demanding data center applications.

Common Types, Their Pros, Cons, and Applications

Network Server Trays come in a variety of designs, each engineered to address different installation needs and operational environments. Understanding these types, along with their respective pros and cons, is essential for selecting the right solution for your data center.

Fixed Server Trays:

Fixed trays are designed as permanent fixtures within server racks, providing a stable, non-adjustable platform for equipment mounting.

Pros:

Enhanced Stability: Their rigid construction minimizes movement, ensuring that heavy equipment remains securely in place.

Simplicity: With no moving parts, fixed trays are straightforward to install and require minimal maintenance.

Cost-Effective: Generally, these trays are less expensive to produce and purchase.

Cons:

Lack of Flexibility: Once installed, they cannot be easily repositioned, which may be a limitation in evolving data center configurations.

Limited Accessibility: Fixed designs might impede quick access to the underlying components during routine maintenance.

Applications:

Fixed trays are ideal for mature data centers with stable configurations, where long-term reliability and minimal adjustments are paramount.

Removable or Adjustable Server Trays:

These trays are designed for flexibility, allowing for easy removal or repositioning as required.

Pros:

Versatility: They enable quick access for maintenance or reconfiguration, making them suitable for dynamic environments.

Ease of Upgrades: Adjustable trays allow for changes in equipment layout without the need for extensive modifications.

Tool-Less Operation: Many models feature tool-less locking mechanisms that simplify installation and removal.

Cons:

Potential for Reduced Rigidity: The inclusion of moving parts can sometimes compromise the overall structural strength compared to fixed trays.

Higher Cost: The added design complexity may lead to a higher price point.

Applications:

Removable trays are commonly used in test labs, evolving data centers, and environments where frequent access to the rear of the rack is needed.

Ventilated Server Trays:

Ventilated trays integrate perforations or mesh panels to facilitate superior airflow.

Pros:

Improved Cooling: Enhanced ventilation helps dissipate heat efficiently, maintaining optimal operating temperatures.

Energy Efficiency: By supporting better thermal management, these trays can contribute to lower cooling costs.

Reduced Hotspots: Effective airflow minimizes the risk of localized overheating in high-density installations.

Cons:

Reduced Physical Protection: The open design may expose internal components to dust or accidental contact.

Maintenance Requirements: In environments with high particulate matter, additional filtering might be necessary.

Applications:

Ventilated trays are best suited for high-performance computing environments and data centers where thermal management is a critical concern.

Custom-Fit Server Trays:

Tailored to meet specific client requirements, custom-fit trays offer unique dimensions and features not available in standard models.

Pros:

Perfect Integration: They are designed to seamlessly match non-standard rack configurations or specific functional requirements.

Enhanced Features: Custom options may include integrated cable management channels, branding elements, or specialized mounting systems.

Optimized Performance: Custom designs ensure that every aspect of the tray meets the exact needs of the installation.

Cons:

Longer Lead Times: The customization process can extend production timelines compared to off-the-shelf products.

Higher Costs: Tailored solutions typically involve increased production costs due to unique specifications.

Applications:

Custom-fit trays are ideal for organizations with specialized data centers, unique design constraints, or those seeking to differentiate their infrastructure through bespoke solutions.

Hybrid Server Trays:

Hybrid trays combine elements from fixed, adjustable, and ventilated designs to offer a versatile solution.

Pros:

Balanced Features: They provide a mix of stability, flexibility, and thermal management in a single product.

Modular Design: Hybrid trays are often designed to be reconfigurable, allowing for future expansion and adjustments.

Cost-Effective Adaptability: By merging multiple functionalities, they offer a comprehensive solution without the need for multiple separate components.

Cons:

Complex Installation: The multi-feature design may require more sophisticated installation procedures.

Higher Initial Investment: The advanced design and added functionality can result in a higher upfront cost.

Applications:

Hybrid trays are particularly useful in state-of-the-art data centers where diverse operational demands require a solution that can adapt to both static and dynamic configurations.

In summary, the choice among fixed, removable, ventilated, custom-fit, and hybrid Network Server Trays depends on factors such as the stability required, ease of access for maintenance, thermal management needs, and budget constraints. Fixed trays offer straightforward, reliable performance for static setups; removable trays provide unmatched flexibility for dynamic environments; ventilated trays excel in thermal efficiency; custom-fit trays cater to specialized requirements; and hybrid trays deliver a balanced solution for multi-faceted challenges.

Materials Used in Network Server Trays: Advantages and Disadvantages

The material selection for Network Server Trays is a critical decision that influences durability, thermal performance, weight, and overall aesthetic appeal. At HULK Metal, we employ a range of high-quality materials to produce trays that meet stringent data center requirements. Below is an analysis of the most common material options along with their pros and cons.

Steel:

Steel is widely recognized for its exceptional strength and durability.

Advantages:

Robustness: Steel trays, typically manufactured with a thickness of 1.5–2.5 mm, provide superior structural integrity and can support heavy loads without flexing.

Heat Dissipation: Due to its high thermal conductivity, steel aids in dissipating heat, which is critical in high-density environments.

Longevity: With appropriate coatings, steel exhibits excellent resistance to wear and can maintain its performance over many years.

Disadvantages:

Weight: Steel is considerably heavier, often weighing between 3 to 5 kg per tray, which can complicate installation and may require additional reinforcement in rack systems.

Corrosion Risk: Without proper anti-corrosive treatments, steel can rust, particularly in humid or chemically aggressive environments.

Aesthetic Limitations: The industrial look of raw steel may not align with the modern, sleek design desired in some data centers.

Aluminum:

Aluminum offers a strong yet lightweight alternative to steel.

Advantages:

Lightweight: Aluminum trays typically weigh around 2 to 3 kg, making them easier to handle and reducing the load on rack structures.

Corrosion Resistance: Aluminum naturally resists corrosion, which minimizes maintenance and extends the life of the tray.

Modern Appearance: The smooth finish of aluminum provides a clean, contemporary look that enhances the overall aesthetic of a data center.

Disadvantages:

Cost: The raw material cost of aluminum is generally higher, which may lead to increased production expenses.

Lower Impact Resistance: Although durable, aluminum may not withstand heavy impacts as well as steel, limiting its use in some high-security applications.

Finish Variability: The final appearance of aluminum can vary based on the manufacturing process and may require additional finishing for uniformity.

High-Grade Plastics (PVC, Polycarbonate):

High-grade plastics are increasingly used in applications where cost efficiency and design flexibility are paramount.

Advantages:

Economical: Plastics are often less expensive than metals, providing a cost-effective solution for budget-sensitive projects.

Malleability: These materials can be molded into intricate designs, allowing for integrated features such as ventilation patterns or cable management channels.

Lightweight Construction: Typically weighing less than 2 kg, plastic trays are very easy to handle and install.

Disadvantages:

Thermal Sensitivity: Plastics generally have lower heat resistance, which can lead to deformation in high-temperature environments.

Lower Structural Strength: While adequate for many applications, high-grade plastics may not offer the same load-bearing capacity as metal alternatives.

Potential Degradation: Over time, exposure to UV light and chemicals can cause plastics to discolor or become brittle if not properly treated.

Composite Materials and Hybrids:

Composite materials, such as fiber-reinforced polymers (FRP), combine the strengths of multiple materials.

Advantages:

Optimized Performance: Composites are engineered to provide a balance of high strength, low weight, and excellent thermal properties.

Customization: These materials offer flexibility for bespoke designs that integrate additional features like anti-corrosion layers or enhanced ventilation structures.

Durability: Composites are highly resistant to chemical exposure and corrosion, making them suitable for harsh environments.

Disadvantages:

Production Complexity: Manufacturing composite trays requires specialized equipment and expertise, potentially leading to longer lead times and higher costs.

Repair Challenges: In the event of damage, composite materials can be more difficult to repair than traditional metals or plastics.

Cost Considerations: The advanced technology involved in producing composites can result in a higher initial investment compared to standard materials.

Hybrid Solutions:

Some server trays employ a combination of materials—for example, an aluminum frame with plastic panels—to achieve a balanced set of attributes.

Advantages:

Balanced Attributes: Hybrid trays aim to harness the strength of metals while taking advantage of the lightweight and flexible properties of plastics.

Design Flexibility: The combination allows for innovative designs that optimize both structural integrity and ease of installation.

Cost Efficiency: By strategically using each material where it performs best, manufacturers can offer a product that meets performance standards without unnecessary expense.

Disadvantages:

Integration Complexity: Combining different materials requires precise engineering to ensure long-term compatibility and performance.

Potential Inconsistencies: Variations in material properties may lead to challenges in achieving a uniform finish and consistent durability over time.

Higher Manufacturing Costs: The complexity of a hybrid system can drive up production costs, particularly for highly customized solutions.

In conclusion, selecting the right material for Network Server Trays depends on the specific operational requirements and budget constraints of your data center. Steel is preferred for its unmatched strength and longevity, while aluminum offers a lightweight and corrosion-resistant alternative with a modern appearance. High-grade plastics provide an economical and flexible option, and composite or hybrid solutions deliver tailored performance that combines the best features of multiple materials. At HULK Metal, our expertise in material selection and advanced manufacturing processes ensures that each tray is optimized for durability, thermal management, and aesthetic appeal.

Key Considerations When Choosing a Contract Manufacturer for Network Server Trays

Choosing the right contract manufacturer for your Network Server Trays is a pivotal decision that can directly impact the quality, reliability, and performance of your data center infrastructure. Here are the key considerations to keep in mind when evaluating potential manufacturing partners:

Industry Experience and Technical Expertise:

Select a manufacturer with a proven track record in fabricating server infrastructure components. Experience in precision metal and plastic processing is vital. At HULK Metal, our extensive background in sheet metal fabrication and contract manufacturing ensures that every tray is engineered to meet rigorous industry standards.

Advanced Production Capabilities:

Ensure that the manufacturer utilizes state-of-the-art production equipment capable of maintaining strict tolerances—for example, ensuring tray thickness is consistently within 1.5–2.5 mm and dimensional accuracy within ±0.2 mm. A facility with modern CNC machinery, automated cutting systems, and robust quality control mechanisms is essential for delivering products that perform reliably in demanding data center environments.

Quality Control and Certification:

A reputable manufacturer will have comprehensive quality control protocols and relevant industry certifications. Look for detailed quality assurance processes that cover every production phase—from raw material sourcing to final inspection. At HULK Metal, our commitment to quality is evident in our rigorous testing and certification processes, which ensure that every Network Server Tray meets or exceeds performance benchmarks.

Customization and Flexibility:

Your data center may require trays with specific dimensions, integrated cable management features, or unique finishes. Choose a partner that offers high levels of customization and can rapidly adapt to design modifications. A flexible production process not only accommodates your current needs but also allows for future adjustments as technology and requirements evolve.

Integrated Supply Chain and Logistics:

A manufacturer with an end-to-end integrated supply chain—from raw material procurement and fabrication to packaging and logistics—can ensure timely delivery and consistent product quality. This integration minimizes production delays and streamlines the manufacturing process, ensuring that your project remains on schedule. HULK Metal's robust supply chain management is designed to deliver quality products reliably, even in large-scale production runs.

Transparent Pricing and Cost Efficiency:

While quality is paramount, pricing remains a critical factor. Look for a manufacturer that provides clear, detailed quotations without hidden costs. Transparent pricing models help you assess the value offered by each partner. Our competitive pricing at HULK Metal reflects our commitment to delivering high-quality products while ensuring cost efficiency throughout the production process.

Communication and Customer Support:

Effective communication is essential during every stage of the project. Choose a manufacturer that offers dedicated project management and responsive customer support. Regular updates and open channels of communication ensure that any issues are quickly addressed, and modifications can be implemented seamlessly. At HULK Metal, our customer service team is always available to provide personalized support and expert guidance.

After-Sales Service and Warranty:

A strong after-sales support system is crucial for addressing any post-production concerns. Inquire about warranty policies, return procedures, and repair services. A manufacturer that stands behind its products will offer comprehensive support, ensuring that any defects or issues are promptly resolved. This commitment to after-sales service can significantly reduce downtime and maintenance costs in the long run.

Innovation and Future-Proofing:

Finally, partner with a manufacturer that invests in research and development to stay ahead of industry trends. Continuous improvement in production processes and product design ensures that your Network Server Trays remain competitive and compatible with future technological advancements. HULK Metal's ongoing innovation in material processing and precision fabrication provides our clients with future-proof solutions that evolve with their needs.

By carefully evaluating these factors—industry expertise, advanced production capabilities, stringent quality control, customization flexibility, integrated supply chain management, transparent pricing, effective communication, reliable after-sales support, and a commitment to innovation—you can confidently select a contract manufacturing partner that aligns with your strategic objectives. At HULK Metal, we combine all these critical elements to deliver Network Server Trays that not only meet but exceed your expectations, providing the durability, performance, and aesthetic appeal required for modern data centers.

Article Navigation

Article Navigation

Industries

Foundries

-

November.21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October.18, 2024

HULK Metal Fabrication

READ MORE

-

February.26, 2025

A Comprehensive Guide to Network Server Racks

READ MORE

-

February.24, 2025

Superior Network Server Cable Management Solutions by HULK Metal

READ MORE

-

February.21, 2025

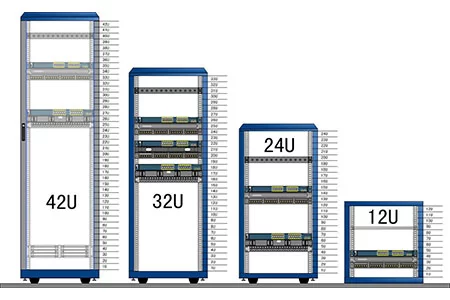

1U, 2U 18U, 42U, What That Mean

READ MORE