Network server racks are the backbone of any data center, providing the framework that holds your essential IT equipment. This guide explores the key factors to consider when choosing an OEM factory to manufacture your network server racks. We detail the

Your Comprehensive Guide to Selecting the Ideal OEM Partner for Network Server Rack Production

How to Choose a Suitable OEM Factory to Produce Your Network Server Racks

-

Home>

-

Blog>

-

Technology>

Choose a Suitable OEM Factory to Produce Your Network Server Racks

The Backbone of Data Centers

In today's digital world, data centers serve as the nerve centers that power everything from cloud services to enterprise IT infrastructure. At the heart of every data center are network server racks—sturdy, meticulously engineered frameworks that organize and secure your servers, switches, and other critical equipment. Yet, the reliability and performance of these racks hinge on the quality of their manufacturing process.

Choosing the right OEM (Original Equipment Manufacturer) factory to produce your network server racks is a decision that can significantly affect your data center's efficiency, scalability, and overall operational reliability. A capable OEM partner will transform your technical drawings and specifications into high-quality products that meet rigorous industry standards. This guide will walk you through the essential factors to consider—from understanding the different types of racks available to evaluating production capabilities and quality control measures.

Whether you need standard racks, high-density configurations, modular systems, or even custom-designed solutions, selecting the right OEM factory is paramount. Let's dive into what you should look for when making this crucial decision.

Understanding Network Server Racks and Their Types

Before choosing an OEM partner, it's important to understand the different types of network server racks available. Each type is designed to meet specific needs and applications within a data center.

Standard Racks

Overview:

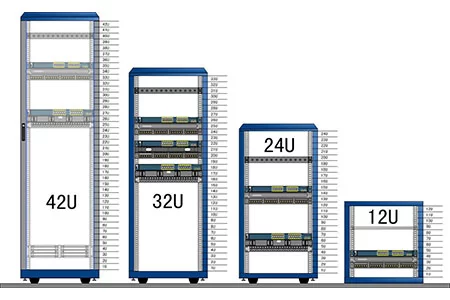

Standard racks are the most widely used in data centers. They are typically available in common configurations such as 42U or 45U, providing a uniform framework for mounting a variety of IT equipment.

Key Features:

Uniform Dimensions:

Standard racks adhere to industry norms, ensuring compatibility with a wide range of servers and accessories.

Versatility:

Suitable for small, medium, or large-scale deployments.

Ease of Integration:

Their standardized design simplifies installation, maintenance, and upgrades.

High-Density Racks

Overview:

High-density racks are engineered to maximize space utilization in environments where computing power must be consolidated into a limited area. They are ideal for organizations that require maximum performance without expanding their physical footprint.

Key Features:

Compact Design:

Optimized for minimal space usage, allowing more equipment per rack.

Enhanced Cooling Solutions:

Integrated features to manage increased heat loads.

Robust Construction:

Capable of supporting a larger number of heavy servers while maintaining stability.

Modular Racks

Overview:

Modular racks offer flexibility and scalability. Their design allows for easy reconfiguration, making them a great choice for data centers that expect evolving needs or frequent upgrades.

Key Features:

Adaptability:

Modules can be added, removed, or rearranged according to changing requirements.

Customizable Layouts:

Support various configurations to optimize airflow, cable management, and equipment placement.

Future-Proofing:

Easily expandable to accommodate new technologies or increased capacity over time.

Custom Racks

Overview:

For data centers with unique or specialized requirements, custom racks provide tailored solutions that standard options cannot offer. These are designed based on specific technical drawings and production orders.

Key Features:

Tailored Solutions:

Designed to meet precise dimensions, integrated features, and performance criteria.

Unique Integrations:

May include specialized cooling systems, advanced cable management, or proprietary mounting mechanisms.

Optimized for Specific Workloads:

Custom racks can be engineered to support specific equipment or environmental conditions, ensuring optimal performance.

Understanding these types of network server racks is the first step in determining which products your OEM partner needs to manufacture. Each type serves a unique purpose and has its own set of specifications that must be met during production.

Key Factors to Consider When Choosing an OEM Factory

When it comes to choosing an OEM factory for producing your network server racks, several critical factors should guide your decision. Here, we explore each factor in detail to help you make an informed choice.

Experience and Technical Expertise

Importance:

Experience is a strong indicator of reliability and technical proficiency. An OEM factory with a long history in metal processing and sheet metal fabrication is more likely to handle complex orders and deliver products that meet precise specifications.

What to Evaluate:

Industry Track Record:

Look for a factory with a proven history of producing network server racks and related accessories.

Specialization:

Ensure they have specific expertise in manufacturing different rack types—standard, high-density, modular, and custom.

Technical Resources:

Assess the capability of their engineering team to support design modifications, troubleshoot issues, and offer technical advice.

A partner with extensive experience will likely be more adept at streamlining production and ensuring that the final product meets your expectations.

Advanced Production Capabilities

Importance:

High-quality production is the foundation of reliable network server racks. Advanced manufacturing equipment and technology ensure that every component is produced with precision and consistency.

What to Evaluate:

Precision Machinery:

The OEM should use modern equipment such as laser cutting machines, CNC bending tools, and automated stamping systems capable of achieving tolerances as tight as ±0.2 mm.

Material Versatility:

Check if the facility is experienced in processing a range of materials (steel, aluminum, high-grade composites) within specific thickness ranges (typically 1.5 mm to 2.5 mm).

Scalability:

The OEM must be able to handle both small-batch prototypes and large-scale production runs without compromising quality.

Customization Flexibility:

Ensure that they can adjust production lines for custom designs, integrated features (like cable management or ventilation slots), and unique finishing requirements.

An OEM with advanced production capabilities can reliably produce network server racks that meet exacting industry standards, ensuring durability and efficiency.

Rigorous Quality Control and Certifications

Importance:

Robust quality control practices minimize defects and ensure that every rack meets safety, durability, and performance standards. This is essential for reducing downtime and maintenance costs in your data center.

What to Evaluate:

Quality Assurance Protocols:

The OEM should have continuous in-process inspections and final product testing to verify dimensional accuracy, load-bearing capacity, and thermal performance.

Industry Certifications:

Look for certifications such as ISO 9001, which indicate adherence to recognized quality standards.

Traceability:

The ability to trace each component from raw material sourcing to final delivery offers additional assurance of quality.

An OEM with a solid quality control system will deliver products that stand the test of time and ensure operational reliability.

Customization and Design Flexibility

Importance:

Every data center has unique requirements. Customization ensures that your network server racks are tailor-made to fit your specific infrastructure, providing features that optimize performance and efficiency.

What to Evaluate:

Tailored Solutions:

The OEM should be capable of producing racks with custom dimensions, integrated features (e.g., cable management clips or enhanced ventilation), and specific surface finishes.

Collaborative Design:

Look for a partner willing to work closely with your design team to refine drawings and optimize designs for manufacturability.

Rapid Prototyping:

The ability to quickly produce prototypes allows for iterative testing and improvements, reducing the risk of production errors.

A flexible OEM partner who offers customization will help you achieve a perfect match between your design requirements and the final product.

Supply Chain Integration and Logistics

Importance:

A fully integrated supply chain ensures that every step of the production process—from raw material procurement to final product delivery—is managed efficiently, reducing delays and ensuring consistent quality.

What to Evaluate:

End-to-End Capabilities:

The OEM should manage everything from sourcing materials and production to quality control, packaging, and logistics.

Inventory Management:

Robust systems for handling varying order volumes are crucial, particularly for large-scale deployments.

Timely Delivery:

Reliable logistics and on-time shipments are vital to keeping your project on schedule.

Strong supply chain integration minimizes disruptions and ensures that you receive your network server racks as planned.

Transparent Pricing and Cost Effectiveness

Importance:

While quality is essential, cost is always a consideration. Transparent pricing helps you understand the value of your investment and avoid unexpected expenses.

What to Evaluate:

Clear Quotations:

Ensure that the OEM provides detailed cost breakdowns covering raw materials, labor, finishing, and logistics.

Competitive Pricing:

Compare proposals from multiple OEMs, but remember that the lowest price should not come at the expense of quality.

Long-Term Value:

Consider the total cost of ownership, including potential savings from reduced maintenance and lower downtime.

Clear and competitive pricing ensures you get a cost-effective solution without compromising on quality.

Communication and After-Sales Support

Importance:

Effective communication is key to a successful OEM partnership. Equally important is robust after-sales support to address any issues that may arise during or after production.

What to Evaluate:

Dedicated Account Management:

A single point of contact who understands your project and coordinates the entire production process.

Regular Updates:

The OEM should provide proactive communication regarding production progress and any potential delays or issues.

After-Sales Service:

Look for clear policies on returns, exchanges, and replenishments for products with quality issues or shipment shortages. (For HULK Metal, note that their after-sales support covers quality problems or short shipments.)

A partner with strong communication and after-sales support will help ensure that your project runs smoothly and any issues are resolved quickly.

Sustainability and Innovation

Importance:

As environmental standards evolve and technology advances, partnering with an OEM that prioritizes sustainability and continuous innovation can provide long-term benefits.

What to Evaluate:

Eco-Friendly Practices:

Determine if the OEM employs energy-efficient processes, waste reduction strategies, and sustainable materials.

Research and Development:

An OEM that invests in R&D is more likely to adopt cutting-edge production techniques and innovative solutions.

Adaptability:

Choose a partner who stays ahead of industry trends and can incorporate new technologies or design improvements as needed.

Sustainable and innovative practices not only reduce environmental impact but also enhance product quality and reliability over time.

Evaluating Proposals and Conducting Factory Visits

Once you have shortlisted potential OEM partners based on the criteria above, it is important to evaluate their proposals and, if possible, conduct on-site factory visits.

Requesting Detailed Proposals

When soliciting proposals, include the following details in your request:

Production Capabilities:

Ask for a comprehensive description of their manufacturing equipment, production processes, and quality control systems.

Customization Options:

Inquire about their ability to meet your specific design requirements, including any unique features or custom finishes.

Lead Times and Scalability:

Request information on production timelines, order volume capacities, and the flexibility to scale up if needed.

Cost Breakdown:

Ensure that each proposal includes transparent pricing with detailed breakdowns of all costs.

References:

Although case studies are not required, asking for examples of similar projects can help verify their capabilities.

By comparing detailed proposals, you can gauge each partner's ability to meet your production needs and deliver high-quality network server racks.

Conducting Factory Visits

Whenever possible, visiting the manufacturing facility provides valuable insights into the OEM's operations. During the visit, consider the following:

Production Environment:

Assess the condition and modernity of their equipment (e.g., laser cutting, CNC bending, automated stamping systems) and verify that the facility is well-organized and safe.

Quality Control:

Observe how quality is managed at various stages—from raw material inspection to final product testing.

Operational Efficiency:

Evaluate the workflow, production capacity, and flexibility in handling large or customized orders.

Team Expertise:

Interact with the production and technical teams to assess their knowledge, responsiveness, and overall professionalism.

A factory visit helps confirm the information provided in proposals and builds confidence in the OEM's ability to deliver as promised.

Best Practices for a Successful OEM Partnership

Based on industry best practices, here are some tips to ensure a successful partnership with your OEM factory:

Develop Clear and Detailed Specifications

Prepare Comprehensive Designs:

Create detailed design specifications for your network server racks, including dimensions, material requirements, finishing, load capacities, and any integrated features.

Minimize Miscommunication:

Clear specifications help ensure that the OEM fully understands your requirements, reducing the risk of production errors.

Focus on Quality Over the Lowest Price

Invest in Reliability:

While competitive pricing is important, prioritizing quality can save costs in the long term by reducing maintenance and downtime.

Consider After-Sales Support:

Factor in the OEM's after-sales services, such as returns, exchanges, or replenishments for quality issues or shipment shortages.

Maintain Open, Transparent Communication

Establish a Dedicated Contact:

Ensure you have a dedicated account manager to serve as your primary point of contact.

Regular Updates:

Schedule regular progress reports to stay informed throughout the production process.

Promptly Address Changes:

Discuss any design modifications or concerns as soon as they arise to avoid delays.

Plan for Future Scalability

Choose a Flexible Partner:

Select an OEM that can grow with your business, accommodating increased order volumes and new design requirements.

Future-Proof Your Infrastructure:

A scalable partner ensures that your data center infrastructure remains robust and adaptable to future needs.

Emphasize Sustainability and Innovation

Eco-Friendly Practices:

Evaluate the OEM's commitment to sustainable manufacturing processes.

Invest in Innovation:

A partner that continuously improves its production techniques can provide long-term value through better product quality and efficiency.

Conclusion: Making the Right Choice for Your Network Server Racks

Selecting the right OEM factory to produce your network server racks is a multifaceted decision that directly impacts the performance and scalability of your data center. By focusing on critical factors such as experience, production capabilities, quality control, customization, supply chain integration, pricing transparency, and robust communication and after-sales support, you can confidently choose an OEM partner that meets and exceeds your expectations.

Key Takeaways:

Experience and Expertise:

Prioritize OEMs with a proven track record in producing network server racks and related accessories.

Advanced Production Capabilities:

Ensure the facility uses modern, precision equipment that can handle a variety of materials and production scales.

Quality Control:

Robust testing protocols and recognized certifications are essential for consistent product quality.

Customization:

Choose a partner capable of delivering tailored solutions that meet your specific design requirements.

Supply Chain Integration:

An end-to-end supply chain ensures timely delivery and reliable production.

Transparent Pricing:

Detailed cost breakdowns help you understand the true value of your investment.

Effective Communication and After-Sales Support:

A dedicated, responsive partner minimizes risks and ensures smooth operations.

Sustainability and Innovation:

A forward-thinking OEM will provide long-term benefits through eco-friendly practices and continuous improvement.

For instance, HULK Metal offers a comprehensive range of network server rack models produced through advanced contract manufacturing. Their robust production capabilities, stringent quality control processes, and dependable after-sales support for quality issues or shipment shortages make them a strong candidate if you're looking for a partner who can deliver high-quality, reliable, and scalable solutions.

Investing in the right OEM partner is not merely a cost-saving measure—it's a strategic decision that sets the foundation for your data center's success. With a trusted OEM factory by your side, you can build a network infrastructure that is efficient, durable, and ready to scale with your growing business needs.

Final Thoughts

Every component in your data center plays a critical role in ensuring seamless operations, and network server racks are no exception. By carefully evaluating potential OEM partners using the guidelines outlined in this article, you can make an informed decision that enhances your data center's performance and reliability. Remember to request detailed proposals, conduct factory visits where possible, and maintain open communication throughout the process.

Choose an OEM partner that not only meets your technical and operational requirements but also shares your commitment to quality, innovation, and sustainable practices. With the right partner, you can ensure that every network server rack is engineered to the highest standards, providing the backbone for a robust, scalable, and efficient data center infrastructure.

Thank you for reading this comprehensive guide on choosing a suitable OEM factory to produce your network server racks. We hope the insights provided here help you make a decision that supports the long-term success of your data center.

Article Navigation

Article Navigation

Industries

Foundries