Network server racks are the backbone of any data center, providing the structural framework that houses servers, switches, and all vital networking equipment. This guide covers every aspect—from a comprehensive introduction and detailed technical paramet

Everything You Need to Know About Network Server Racks

Network Server Racks: A Complete Guide to Design, Specifications, and OEM Selection

-

Home>

-

Blog>

-

Technology>

A Comprehensive Guide to Network Server Racks

Network server racks are the backbone of any data center, providing the structural framework that houses servers, switches, and all vital networking equipment. This guide covers every aspect—from a comprehensive introduction and detailed technical parameters (with specific numbers for plate thickness, width, and more), to the common types of racks and their pros, cons, and applications. We also explore various materials used in rack construction along with their benefits and limitations. Finally, learn the key considerations when choosing an OEM factory to produce your network server racks, ensuring that your data center is efficient, reliable, and future-proof. (Note: When mentioning HULK Metal, only their wide-ranging OEM capabilities and after-sales support for quality issues or shipment shortages are highlighted.)

Comprehensive Introduction to Network Server Racks

Network server racks form the structural foundation of modern data centers, providing a standardized framework to securely house servers, switches, and other critical IT equipment. These racks are designed to optimize space, ensure proper airflow, and enhance system reliability. By organizing equipment in a vertical, modular format, server racks not only improve accessibility and ease of maintenance but also help manage cooling and power distribution effectively. Whether you're outfitting a small server room or a large-scale enterprise data center, high-quality racks are essential for maintaining efficiency and protecting your valuable hardware. Their design is driven by industry standards that ensure compatibility and uniformity across different devices. In essence, a well-engineered network server rack is key to maximizing operational uptime and simplifying future upgrades. Choosing the right rack—and the right manufacturing partner to produce it—lays the groundwork for a robust and scalable IT infrastructure.

Important Parameters of Network Server Racks

Understanding the technical parameters of network server racks is crucial for ensuring that your data center operates efficiently and reliably. These parameters not only dictate the physical dimensions but also affect the overall performance and compatibility of your equipment. Let's examine some of the most critical specifications:

Dimensions and Tolerances

Height (Rack Unit - "U"):

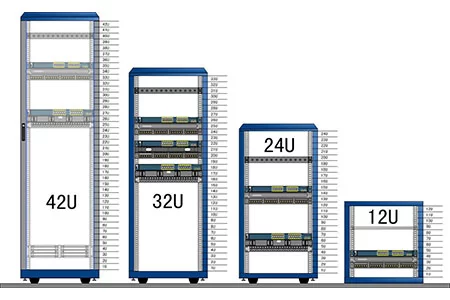

- A standard rack unit (1U) is defined as 1.75 inches (44.45 mm) in height.

- Typical server racks come in configurations such as 42U or 45U, meaning they provide 42 or 45 times that 1.75-inch unit. This allows for a wide variety of equipment sizes and densities.

Width and Depth:

- Width:

Standard rack widths typically range from 600 mm to 800 mm. Most equipment is designed to fit within these confines for seamless integration.

- Depth:

Rack depths can vary significantly, from 600 mm in smaller installations to 1200 mm or more in high-capacity data centers. These dimensions must be precise, with tolerances maintained as tight as ±0.2 mm to ensure components align perfectly.

Material Thickness and Construction

Plate Thickness:

- For the structural components of racks—such as side panels, mounting rails, and reinforcement brackets—material thickness is key.

- Typical thickness ranges for metal parts are between 1.5 mm and 2.5 mm. A thicker material (around 2.0-2.5 mm) often translates to higher durability, particularly in high-density or heavy-load environments, while 1.5 mm might be used for lighter-duty components where ease of installation is a priority.

Reinforcement and Structural Integrity:

- Racks must support substantial weight, so robust construction is essential. Critical load-bearing elements are engineered to sustain weights of 50 kg or more per rack level.

- The design often includes reinforced mounting rails and cross-bracing to prevent bending or warping over time.

Ventilation and Thermal Management

Airflow Optimization:

- Proper cooling is critical in data centers. Racks often incorporate ventilation slots or perforations to facilitate airflow.

- Typical perforation diameters range from 5 mm to 10 mm, arranged in patterns that balance structural integrity with optimal heat dissipation.

Cooling Compatibility:

- The design should ensure that any blank panels or covers do not obstruct airflow. In many cases, manufacturers offer ventilated options that support advanced cooling systems.

Integration Features

Cable Management:

- Many modern racks include integrated cable management systems, such as clips or trays. These features help organize cables, reduce clutter, and enhance airflow.

- Precise dimensions are essential here; even small misalignments can lead to tangled cables and obstructed ventilation.

Mounting and Accessory Compatibility:

- Standardization is critical for ensuring that servers, power distribution units, and other accessories fit seamlessly within the rack.

- Pre-drilled holes and tool-less locking mechanisms are often part of the design to facilitate quick and secure installations.

Environmental and Safety Considerations

Fire Safety and Compliance:

- Materials and finishes are selected to comply with fire safety standards, ensuring that the racks help mitigate fire risks in data centers.

- Coatings and treatments, such as high-quality powder coating, can enhance resistance to corrosion and environmental wear, prolonging the lifespan of the rack.

By understanding these technical parameters, you can ensure that your network server racks are built to the highest standards, providing a secure, efficient, and scalable solution for your data center. Each specification—from the precise 1.75-inch U measurement to the material thickness and ventilation design—plays a critical role in the overall performance of your IT infrastructure.

Common Types, Their Pros, Cons, and Applications of Network Server Racks

Network server racks come in several configurations, each designed to meet specific needs and operational demands. Understanding the common types, along with their advantages and disadvantages, helps you select the best solution for your data center. Here are the primary types:

Standard Racks

Standard racks are the most prevalent and widely used in data centers. They adhere to industry norms and provide a consistent framework for housing servers, switches, and accessories.

Pros:

- Uniformity: Standardized dimensions ensure compatibility with a wide range of equipment.

- Ease of Installation: Simplified design leads to quick and efficient setup.

- Cost-Effective: High-volume production of standard racks often results in lower costs.

Cons:

- Limited Flexibility: They may not accommodate specialized equipment or unusual configurations.

- Basic Features: Standard racks might lack integrated features such as advanced cable management or enhanced ventilation.

Applications:

Standard racks are ideal for general-purpose data centers where a uniform setup is preferred and where the environment is relatively stable with predictable requirements.

High-Density Racks

High-density racks are engineered to maximize space utilization in environments where equipment density is critical. They are designed to support more equipment within a given footprint.

Pros:

- Space Optimization: Allow for the installation of a large number of devices in a limited area.

- Enhanced Cooling: Often incorporate features that improve thermal management in high-load scenarios.

- Robust Construction: Built to handle heavier loads without compromising stability.

Cons:

- Cooling Challenges: Increased density can lead to hot spots if not managed properly.

- Complex Installation: May require additional planning and specialized cooling solutions.

Applications:

High-density racks are best suited for enterprise-level data centers and environments where maximizing computing power in limited space is essential.

Modular Racks

Modular racks offer flexibility and scalability. They allow for reconfiguration as needs change, making them ideal for dynamic data centers.

Pros:

- Adaptability: Modules can be added or removed to tailor the rack to current requirements.

- Customizable Layouts: Supports a variety of configurations to optimize airflow and cable management.

- Future-Proofing: Easily expandable to incorporate new technology as it emerges.

Cons:

- Higher Cost: Modular systems can be more expensive due to their versatility and design complexity.

- Complex Integration: May require additional time and expertise for initial setup and future reconfigurations.

Applications:

Modular racks are perfect for data centers expecting frequent upgrades or reconfigurations. They are also suitable for environments where a flexible layout is needed to accommodate varied workloads.

Custom Racks

Custom racks are produced based on unique design requirements and specifications. They are tailored to meet specific performance, aesthetic, or spatial needs.

Pros:

- Tailored Solutions: Designed to match exact dimensions, integrated features, or performance criteria that off-the-shelf products cannot meet.

- Enhanced Functionality: Can incorporate specialized cooling, cable management, or mounting systems unique to your environment.

- Optimized Performance: Engineered to support specific workloads or environmental conditions.

Cons:

- Longer Lead Times: Custom manufacturing often involves extended production times.

- Higher Cost: Tailored solutions typically come with increased costs due to bespoke design and lower production volumes.

Applications:

Custom racks are ideal for specialized data centers with unique requirements, such as non-standard layouts, high-performance computing needs, or specific security and cooling demands.

Summary of Rack Types

Each type of rack offers distinct advantages and potential drawbacks. Standard racks are best for straightforward deployments, high-density racks excel in space-constrained environments, modular racks offer unmatched flexibility, and custom racks provide bespoke solutions tailored to specific needs. Understanding these differences is key to selecting a product that not only meets your current requirements but can also adapt to future growth and technological advancements.

Materials Used in Network Server Racks and Their Pros and Cons

The materials used in manufacturing network server racks significantly affect their durability, weight, aesthetics, and overall performance. Below is an overview of common materials, along with their advantages and disadvantages:

Steel

Steel is a traditional and popular choice for server racks due to its exceptional strength and durability.

Pros:

- High Strength: Steel racks provide robust support, ideal for heavy equipment and high-density installations.

- Durability: With proper treatment and coatings, steel is highly resistant to wear and tear, ensuring long-term reliability.

- Structural Integrity: Steel's rigidity helps maintain stability and prevents deformation over time.

Cons:

- Weight: Steel racks are heavy, which can complicate installation and may require additional support structures.

- Corrosion Risk: Without adequate protective coatings, steel is susceptible to rust, especially in humid environments.

- Aesthetic Limitations: The industrial look of raw steel may not suit data centers that demand a modern or sleek appearance without additional finishing.

Aluminum

Aluminum is valued for its lightweight properties and natural resistance to corrosion, making it a popular alternative to steel.

Pros:

- Lightweight: Easier to handle and install compared to steel, reducing overall stress on the data center's infrastructure.

- Corrosion Resistance: Aluminum naturally resists corrosion, extending the lifespan of the rack in various environmental conditions.

- Modern Aesthetics: Its smooth finish contributes to a contemporary, clean look in data centers.

Cons:

- Lower Strength: While strong enough for many applications, aluminum may not provide the same level of support as steel for extremely heavy installations.

- Higher Cost: Aluminum can be more expensive than steel in some cases, impacting the overall budget.

- Thermal Conductivity: Aluminum conducts heat well, which can be an advantage for cooling but may require careful design to manage thermal expansion.

High-Grade Plastics and Composites

High-grade plastics (such as PVC or polycarbonate) and composite materials offer a lightweight and cost-effective solution for certain rack components.

Pros:

- Cost-Effective: Generally less expensive than metals, providing a budget-friendly option.

- Lightweight: Ease of installation and reduced load on the overall rack structure.

- Design Flexibility: Plastics can be molded into complex shapes, allowing for integrated features such as cable management or ventilation designs.

Cons:

- Lower Structural Strength: May not be suitable for heavy-duty applications or environments where maximum durability is required.

- Thermal Limitations: Plastics may deform under high temperatures, making them less ideal for high-density, high-heat data centers.

- Aesthetic and Aging: Over time, some plastics may discolor or degrade, particularly if exposed to UV light or harsh chemicals.

Hybrid and Composite Materials

Hybrid solutions often combine the strengths of metals and plastics to deliver a balanced performance profile.

Pros:

- Optimized Performance: By combining materials, hybrid racks can offer the strength of metal with the lightweight benefits of plastics.

- Customizable: Allows for tailored solutions that meet specific performance or aesthetic requirements.

- Enhanced Durability: Composite materials can be engineered for increased resistance to corrosion and environmental factors.

Cons:

- Complex Production: The integration of different materials can complicate manufacturing processes and increase lead times.

- Higher Cost: Advanced composites may come at a premium compared to traditional materials.

- Repair Challenges: In the event of damage, hybrid components may require specialized repair techniques.

Summary of Material Considerations

The choice of material for network server racks depends on balancing strength, weight, cost, and aesthetics. Steel offers unmatched durability and support but at the cost of increased weight. Aluminum provides a modern, lightweight alternative with excellent corrosion resistance, while high-grade plastics and composites offer cost-effective and flexible solutions for less demanding applications. Hybrid materials provide a tailored approach, combining the best attributes of each material, though often at a higher price and production complexity.

Selecting the right material is critical to ensuring that your network server racks are both reliable and efficient, fitting seamlessly into your data center's overall design and operational requirements.

Key Considerations When Choosing an OEM Factory for Network Server Racks

Choosing the right OEM factory to produce your network server racks is a strategic decision that directly influences the performance, scalability, and reliability of your data center. Here are the key factors to consider when selecting an OEM partner:

Experience and Expertise

Why It Matters:

An OEM factory with extensive experience in metal processing and sheet metal fabrication has the technical know-how and proven track record to produce high-quality racks. Look for:

- Industry Experience:

A long history of manufacturing data center components.

- Technical Specialization:

Proven expertise in producing various types of racks—standard, high-density, modular, and custom.

- Engineering Support:

Availability of a knowledgeable technical team to assist with design refinements and troubleshooting.

Advanced Production Capabilities

Why It Matters:

State-of-the-art production capabilities ensure that every rack is manufactured with high precision and consistency. Key factors include:

- Precision Equipment:

Look for advanced laser cutting, CNC bending, and automated stamping systems that achieve tight tolerances (as precise as ±0.2 mm).

- Material Versatility:

The OEM should handle a range of materials (steel, aluminum, plastics, composites) with thicknesses typically between 1.5 mm and 2.5 mm.

- Scalability:

The ability to handle both small prototype runs and large-scale production without compromising quality.

- Customization Flexibility:

Facilities that can adapt to custom designs and integrate specialized features such as enhanced cable management or ventilation systems.

Rigorous Quality Control and Certifications

Why It Matters:

Reliable quality control practices are essential to ensure that every rack meets industry standards for performance and safety.

- Continuous Inspections:

Look for in-process and final quality testing for dimensional accuracy, load capacity, and thermal performance.

- Certifications:

International certifications (e.g., ISO 9001) provide assurance of high-quality manufacturing processes.

- Traceability:

A robust system for tracing components from raw material to finished product minimizes defects and ensures consistency.

Customization and Design Flexibility

Why It Matters:

Data centers often require tailored solutions. An OEM that offers customization ensures your network server racks meet specific design, functionality, and aesthetic requirements.

- Tailored Production:

The ability to produce racks with custom dimensions, integrated cable management features, or unique finishes.

- Collaborative Approach:

A partner willing to work closely with your design team to optimize product specifications.

- Rapid Prototyping:

Quick turnaround on prototypes helps refine designs and minimize production risks.

Integrated Supply Chain and Logistics

Why It Matters:

A fully integrated supply chain ensures seamless production and timely delivery.

- End-to-End Management:

From raw material sourcing to final delivery, the OEM should manage the entire process.

- Efficient Inventory Control:

Robust systems for managing production volumes and order schedules.

- Timely Shipping:

Reliable logistics and on-time delivery are critical to meeting your project deadlines.

Transparent Pricing and Cost Effectiveness

Why It Matters:

Understanding the true cost of production helps you make informed decisions.

- Detailed Quotations:

Request clear, itemized cost breakdowns covering raw materials, labor, finishing, and shipping.

- Competitive Offers:

Compare proposals from multiple OEMs, balancing cost against quality and reliability.

- Total Cost of Ownership:

Consider long-term value, including potential savings from reduced downtime and maintenance costs.

Communication and After-Sales Support

Why It Matters:

Effective communication ensures a smooth production process, while robust after-sales support minimizes the impact of any issues.

- Dedicated Account Management:

A single point of contact who understands your requirements and coordinates production.

- Regular Updates:

Proactive communication regarding progress and any changes or delays.

- After-Sales Service:

Clear policies on returns, exchanges, and replenishments for quality issues or shipment shortages. (For instance, HULK Metal offers after-sales support for quality issues and short shipments.)

Summary of Key Considerations

By focusing on these critical factors—experience, production capabilities, quality control, customization, supply chain integration, pricing transparency, and effective communication—you can choose an OEM partner that will deliver high-quality network server racks tailored to your data center's unique needs. A reliable OEM partner not only produces robust and scalable racks but also provides the after-sales support necessary to ensure long-term operational success.

Final Thoughts

Network server racks are more than just enclosures; they are the backbone of your data center. The right OEM partner can make all the difference by ensuring that every rack is manufactured to the highest standards of precision, durability, and efficiency. By carefully evaluating potential OEM factories based on the criteria outlined in this guide and maintaining clear, detailed specifications throughout the process, you can make a strategic decision that supports the long-term growth and reliability of your IT infrastructure.

Take the time to request detailed proposals, visit manufacturing facilities when possible, and establish open communication with potential partners. A trusted OEM factory—one that values quality, transparency, and innovation—will be a critical asset in building a data center that is both efficient and scalable.

Thank you for reading this comprehensive guide on choosing a suitable OEM factory to produce your network server racks. We hope that the insights provided here empower you to make an informed decision that enhances the performance and reliability of your data center.

Contact us today to discuss your production requirements and receive a competitive, custom-tailored quote from a partner dedicated to excellence in network server rack manufacturing.

Article Navigation

Article Navigation

Industries

Foundries

-

November.21, 2024

HULK Metal Stamping Factory Show

READ MORE

-

October.18, 2024

HULK Metal Fabrication

READ MORE

-

February.21, 2025

Optimized Network Server Blank Panel Solutions for Modern Data Centers

READ MORE

-

February.21, 2025

Choose a Suitable OEM Factory to Produce Your Network Server Racks

READ MORE

-

February.21, 2025

1U, 2U 18U, 42U, What That Mean

READ MORE

-

February.21, 2025

How Should You Choose A Suitable OEM Factory to Produce Your Network Server Accessories

READ MORE